Intelligent magnetic bearing

A magnetic bearing, electromagnetic bearing technology, applied in the direction of bearings, shafts and bearings, mechanical equipment, etc., can solve the problems of low professional efficiency, high labor intensity, high cost, etc., to save installation space, improve sensitivity and accuracy, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] A preferred embodiment of the present invention is described as follows in conjunction with accompanying drawing:

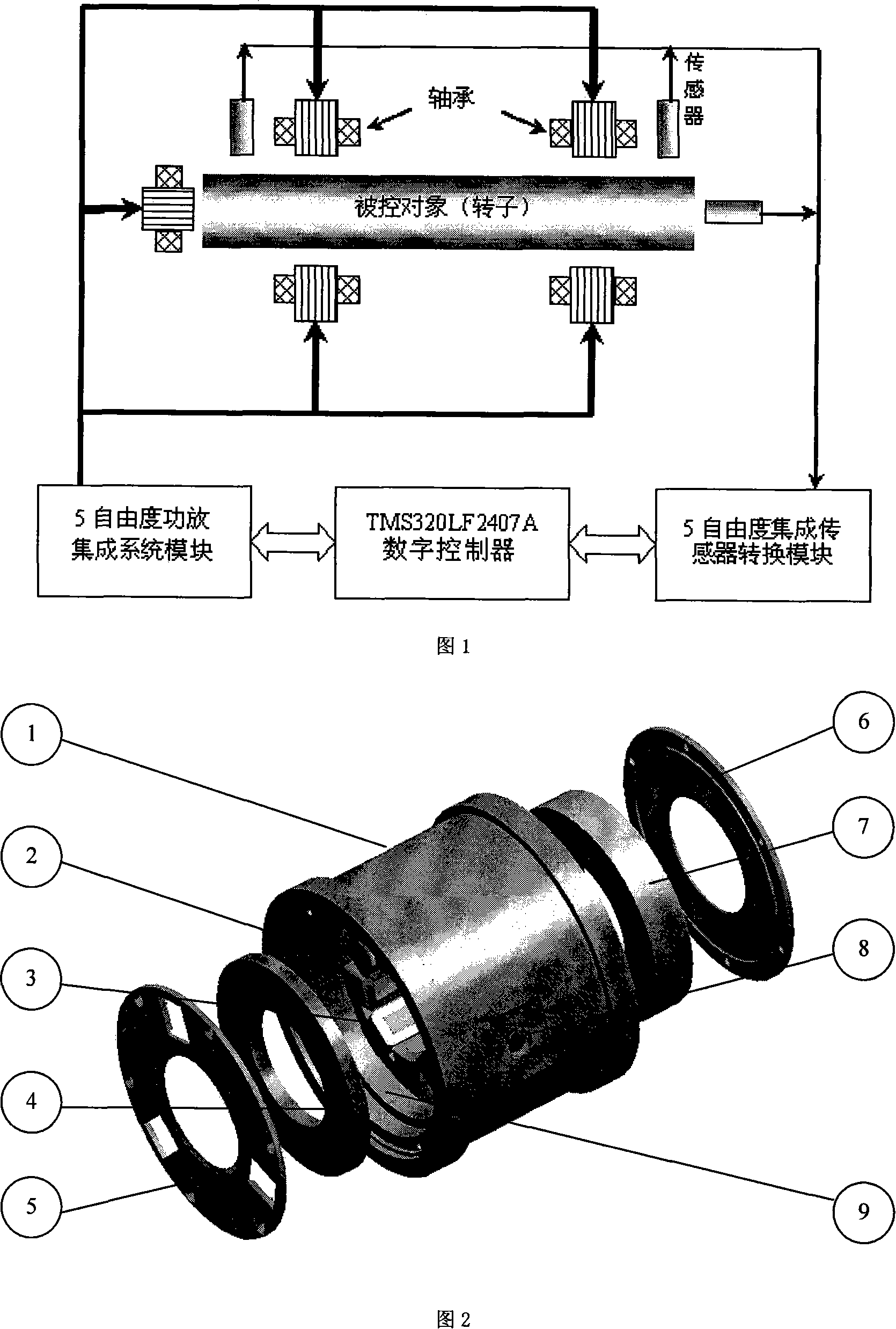

[0031] Fig. 1 is a block diagram of the working principle of the five-degree-of-freedom magnetic suspension bearing system implemented in the present invention, which includes a digital controller, a five-degree-of-freedom power amplifier integrated system module, a five-degree-of-freedom sensor conversion module, 2 radial electromagnetic bearings, 1 An axial magnetic bearing and a rotor. The rotor is the controlled object in the whole system. The sensor detects the movement position of the suspended rotor and feeds the signal back to the digital controller. The controller generates corresponding control signals according to the feedback signals, and then the power amplifier converts the control signals into corresponding control signals. Voltage or current actively controls the electromagnet in the actuator, that is, the electromagnetic bearing, so that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com