Slit coating apparatus

A coating device, a slit-type technology, applied in the direction of photo-engraving process coating equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Since the embodiments of the present invention can be implemented in various forms, the scope of claims of the present invention is not limited to the following embodiments.

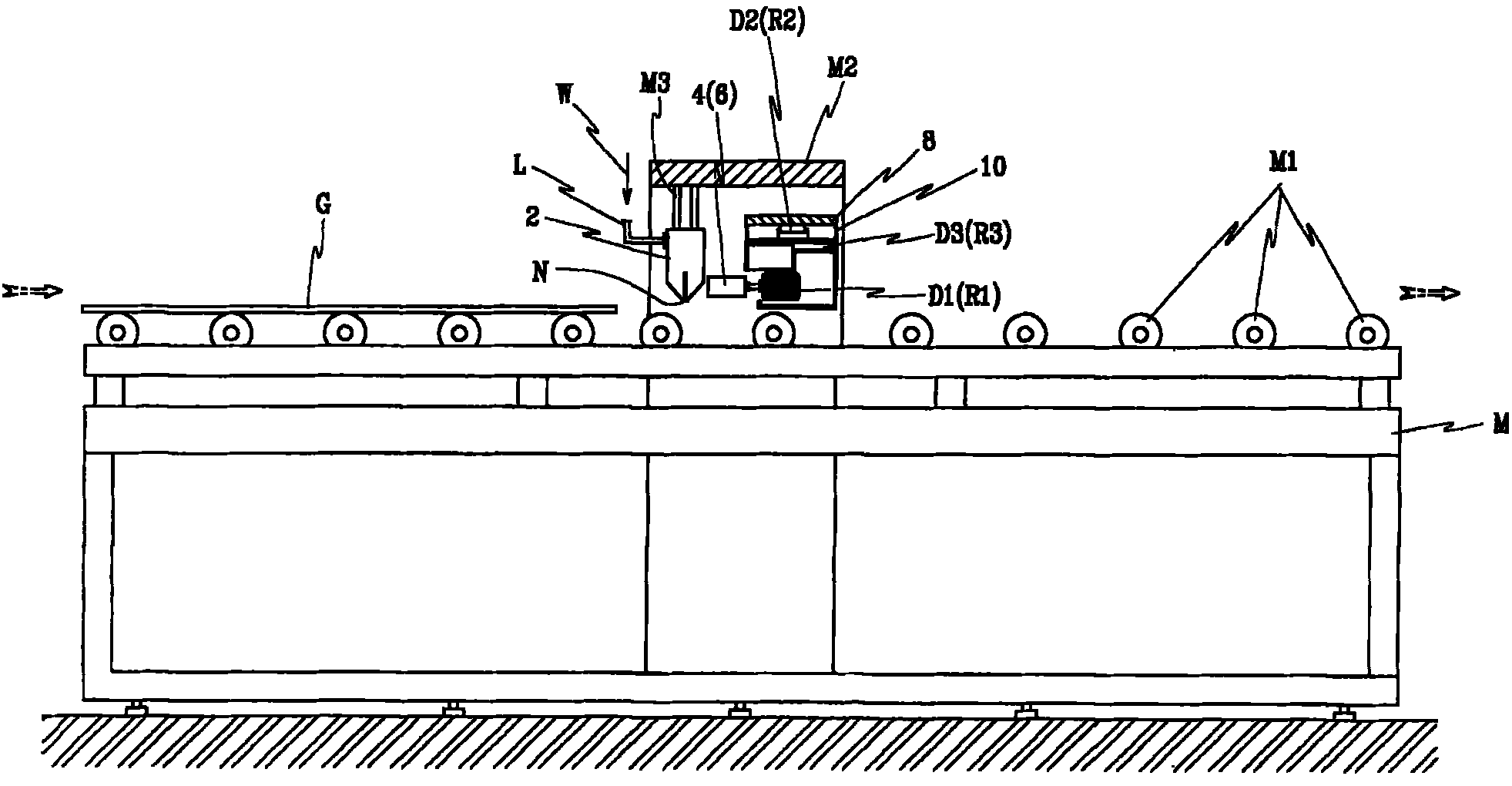

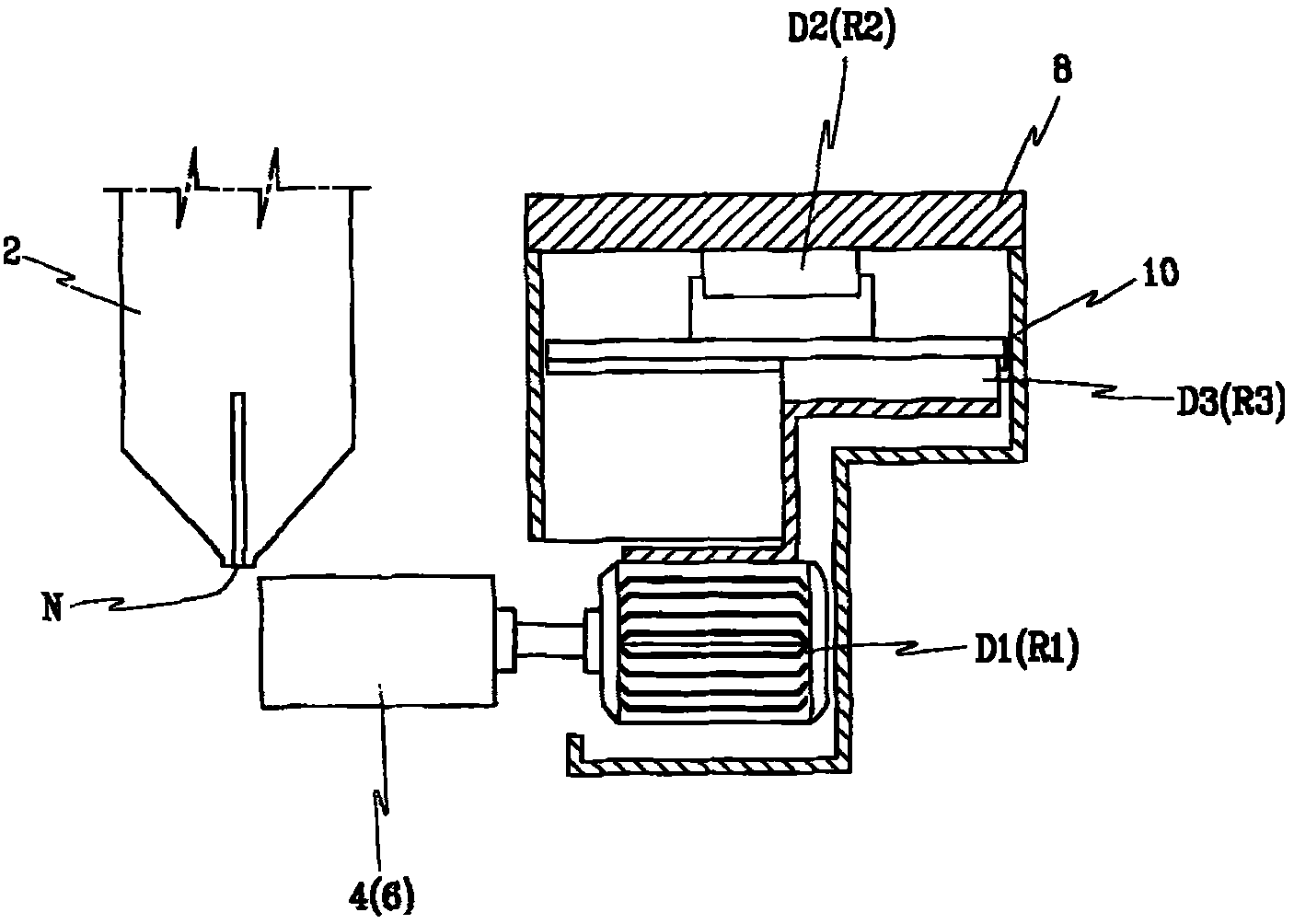

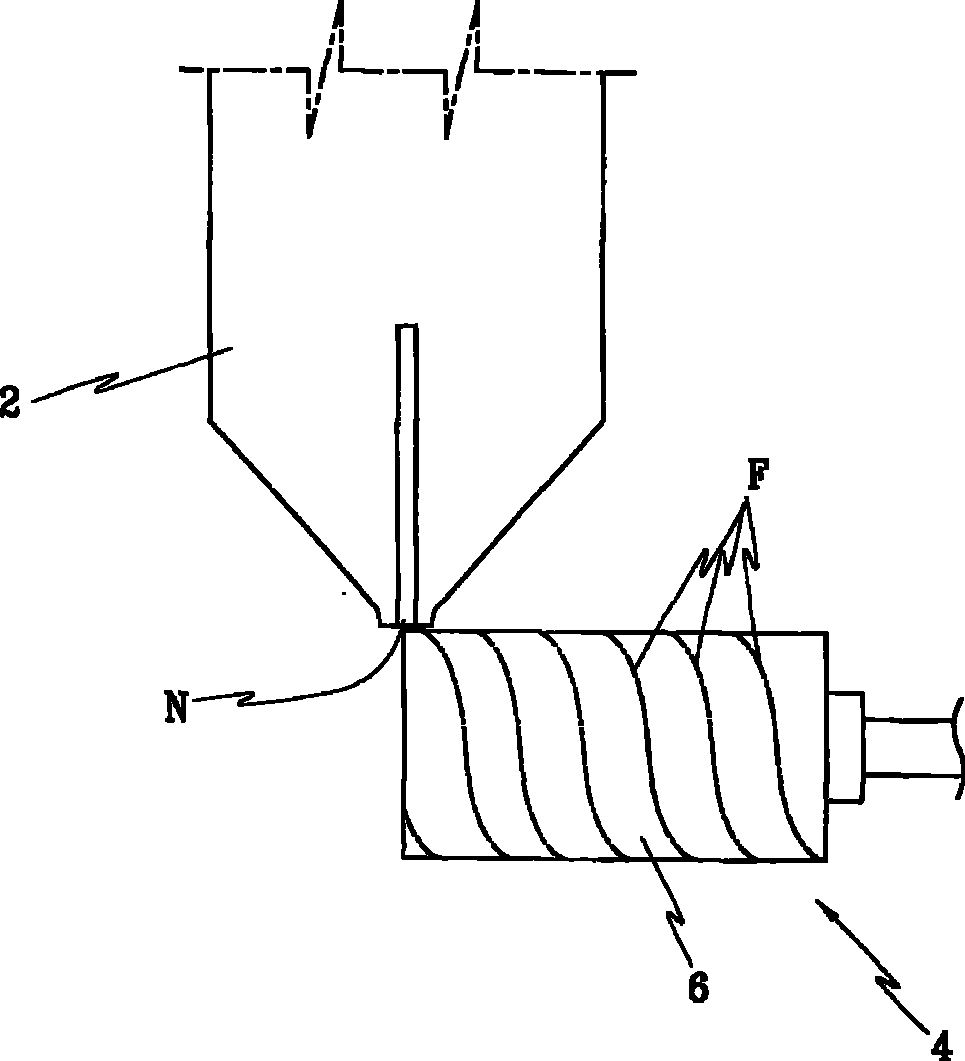

[0041] figure 1 It is a schematic diagram of the overall structure of the slit coating device of the present invention, and the symbol 2 in the figure represents the nozzle body.

[0042] The top view shape of the nozzle body 2 is a rectangle, which is suitable for the usual slit coating operation, and is fixed on one side of the workbench M. The table M is equipped with a conveying device M1 such as a roller conveyor, and has the nozzle body 2 . While the substrate G for a flat panel display (hereinafter referred to as "substrate") is being conveyed by the conveying device M1, a coating operation of applying a photosensitive liquid W such as a photoresist to the substrate G is performed.

[0043] like figure 1 As shown, the nozzle body 2 can be fixed on the support table M2 installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com