Power supply circuit of fluorescence display device

A power supply circuit and display technology, applied in the direction of static indicators, instruments, electrical components, etc., can solve the problems of large noise, multiple costs and time, high power consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

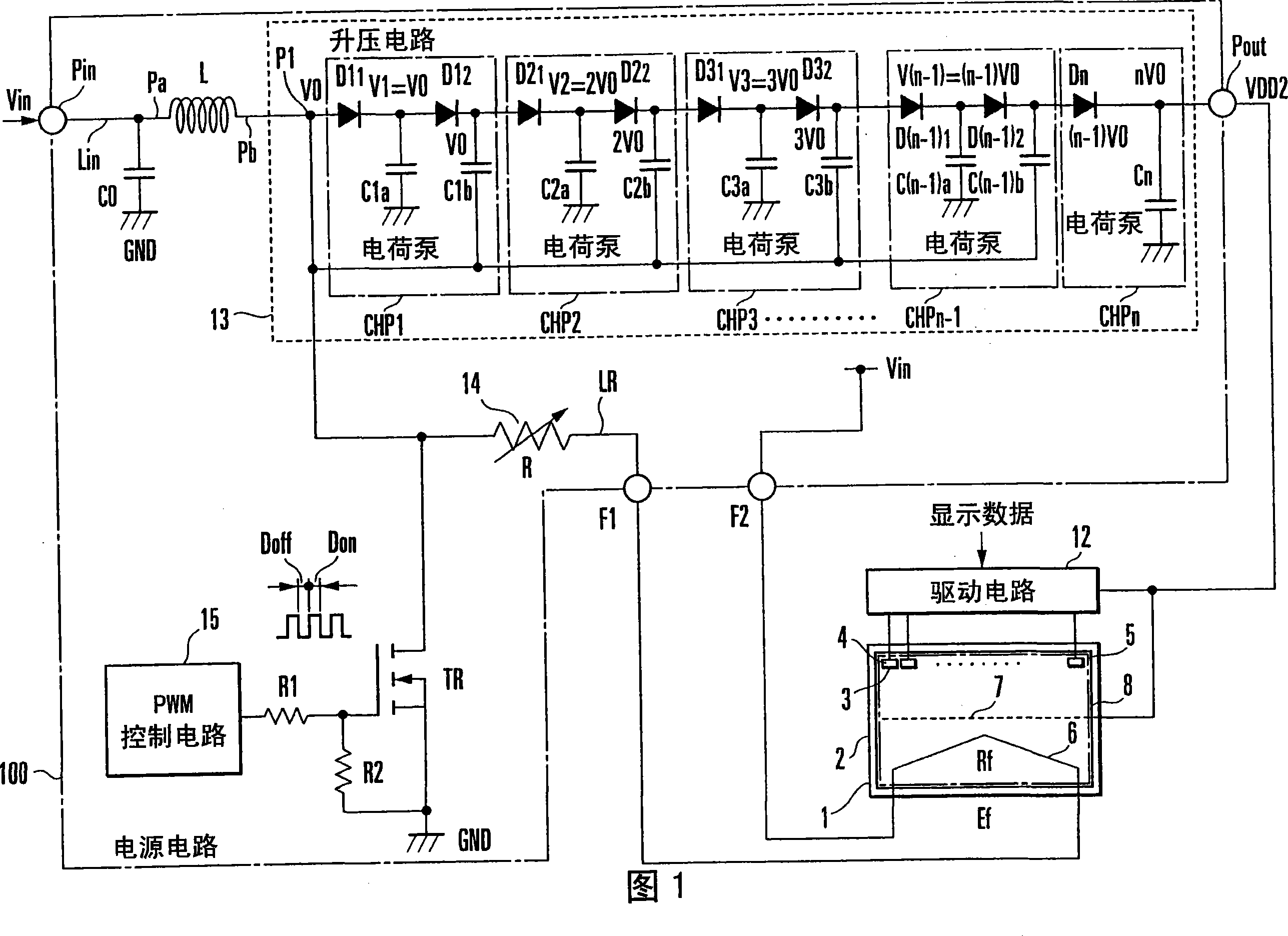

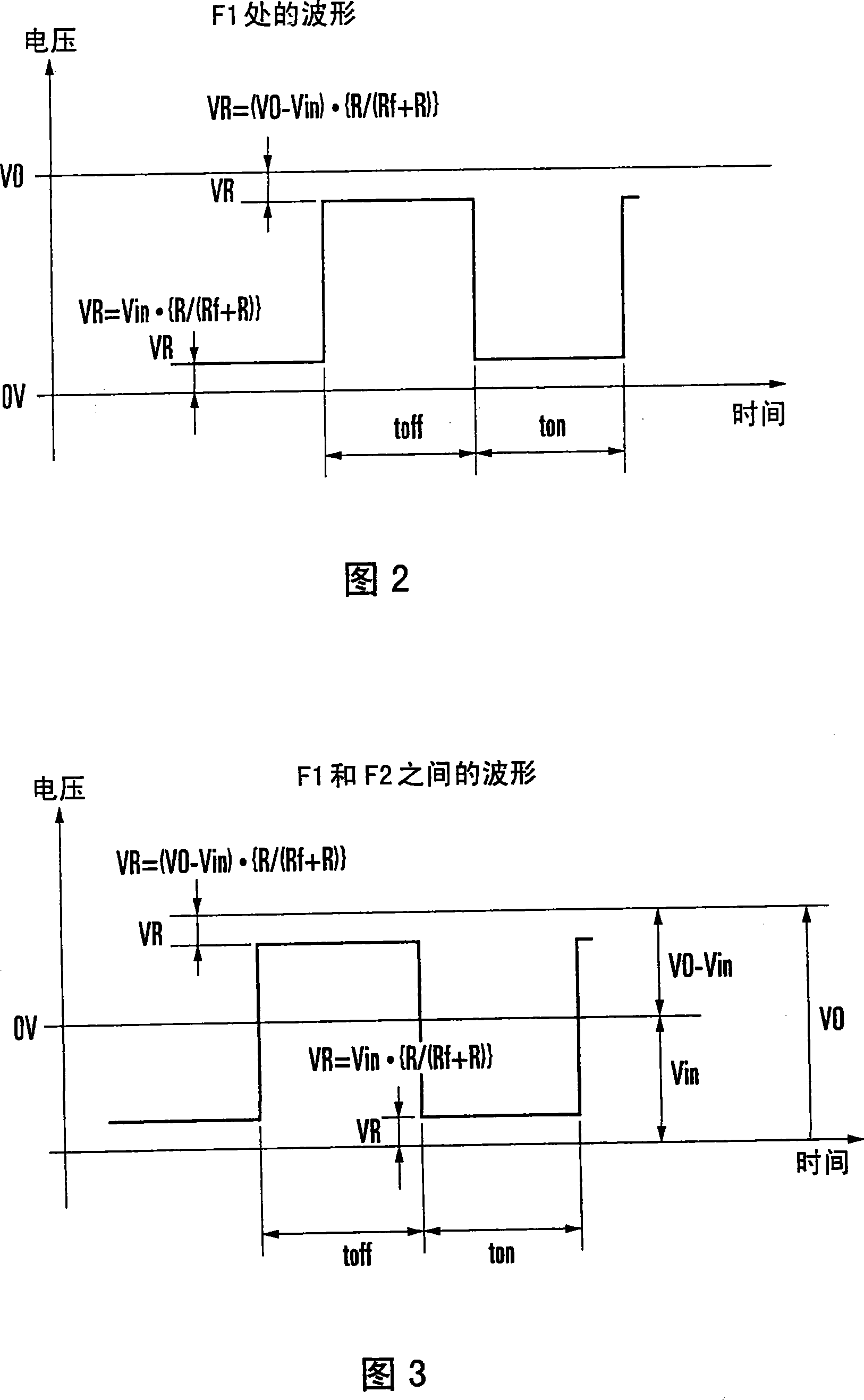

[0039] FIG. 1 is a circuit diagram showing a main part of a power supply circuit according to an embodiment (first embodiment) of the present invention. The power supply circuit 100 includes a capacitor (input smoothing capacitor) CO, a boost coil (inductance element) L, a boost circuit 13, a switching transistor (field effect transistor) TR, a variable resistor (voltage adjustment resistor) 14, and a PWM control circuit 15 and resistors R1 and R2. The power supply circuit has an input terminal Pin, an output terminal Pout, a filament terminal F1 (first terminal) and a filament terminal F2 (second terminal).

[0040] The input voltage (DC voltage) Vin is applied to the input terminal Pin. The DC voltage VDD2 for anode / gate is output from the output terminal Pout. A cathode (filament) 6 of the vacuum fluorescent display tube 1 is connected between filament terminals F1 and F2.

[0041] In the power supply circuit 100 , the boost coil L is provided on the current path Lin bet...

no. 2 example

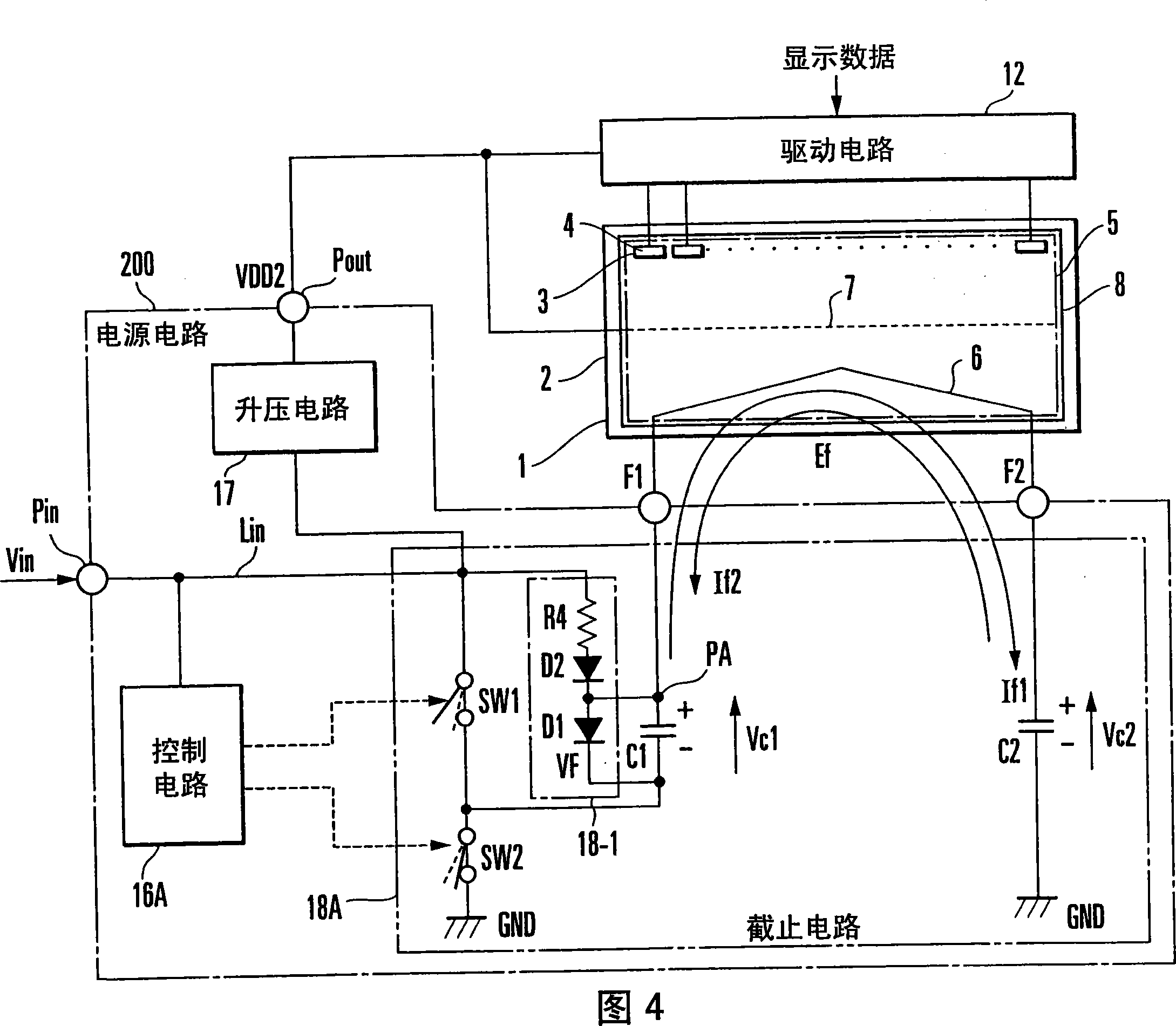

[0097] FIG. 4 shows a main part of a power supply circuit according to another embodiment (second embodiment) of the present invention. The power supply circuit 200 includes a control circuit 16A, a boost circuit 17 and a cutoff circuit 18A, and has an input terminal Pin, an output terminal Pout, and filament terminals F1 and F2. A DC voltage (input voltage) Vin is applied to the input terminal Pin. The DC voltage VDD2 for anode / gate is output from the output terminal Pout. A cathode (filament) 6 of the vacuum fluorescent display tube 1 is connected between filament terminals F1 and F2.

[0098] The cut-off circuit 18A includes a first switch SW1, a second switch SW2, a resistor R, diodes D1 and D2, and capacitors C1 and C2. The switches SW1 and SW2 are connected in series between the input line Lin for the DC voltage Vin and the ground (GND). In this series connection, the switch SW1 is on the input line Lin side of the DC voltage Vin, and the switch SW2 is on the ground s...

no. 3 example

[0142] FIG. 8 shows an application of the power supply circuit 200 shown in FIG. 4 . In the power supply circuit 300, the third and fourth switches SW3 and SW4 are connected in series between the input line Lin for the DC voltage Vin and the ground line. In this series circuit, the switch SW3 is located on the input line Lin side of the DC voltage Vin, and the switch SW4 is located on the ground line side. Capacitor C2 is connected between filament terminal F2 and node PB between switches SW3 and SW4.

[0143] The switch SW1 and the switch SW4 constitute a first switch pair, and the switch SW2 and the switch SW3 constitute a second switch pair. The control circuit 16B periodically and alternately turns on / off the first pair of switches ( SW1 and SW4 ) and the second pair of switches ( SW2 and SW3 ) in opposite directions.

[0144] That is, the control circuit 16B periodically repeats "simultaneously turning off the second switch pair (SW2 and SW3) while simultaneously turnin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com