Casting mould, process and device for casting metal melts

A metal melt and casting mold technology, applied in the direction of molten metal supply equipment, metal processing equipment, casting equipment, etc., can solve the problems of blockage impact, inner wall penetration of the mold, etc., so as to slow down the blockage impact and prevent sudden pressure rise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

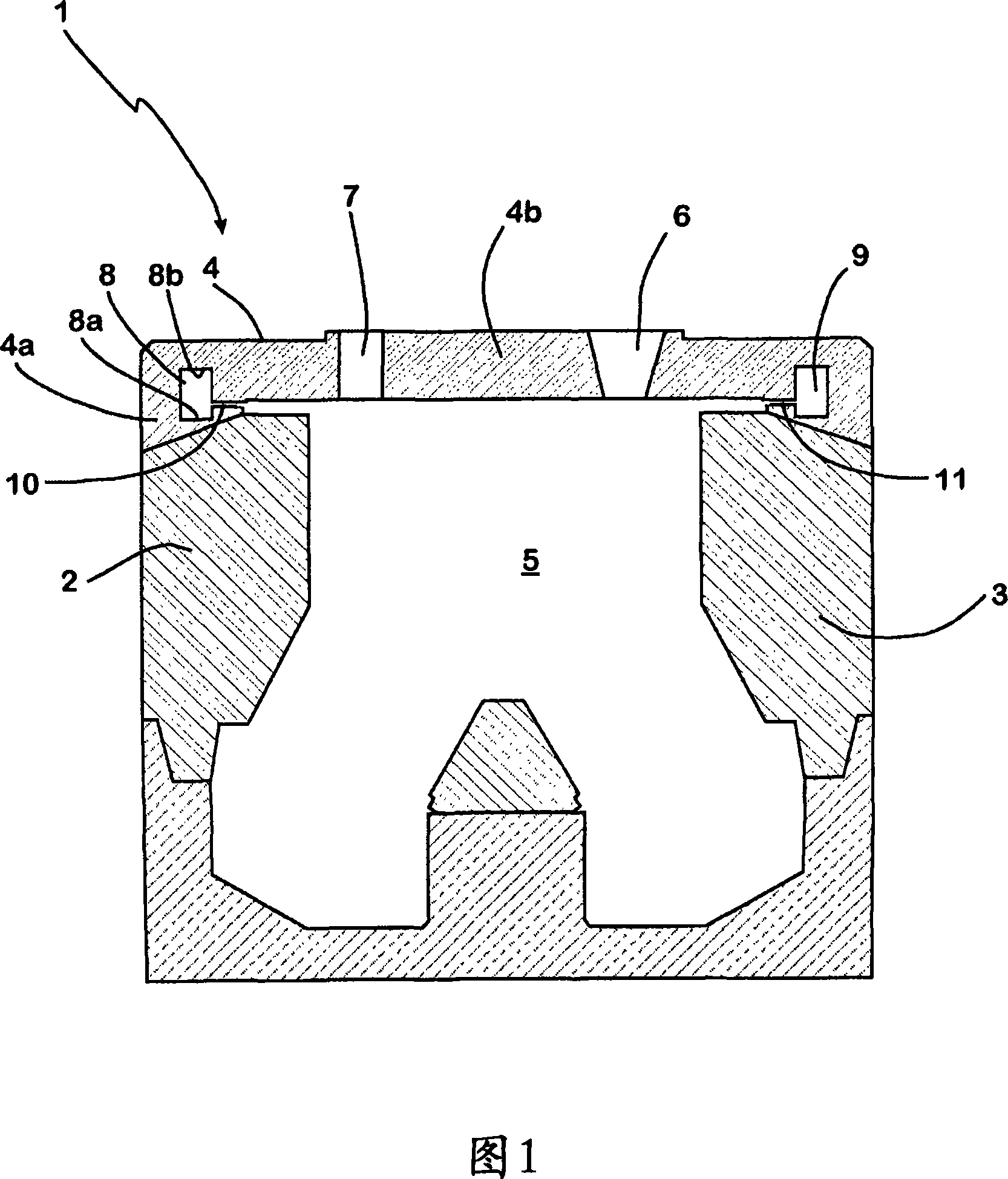

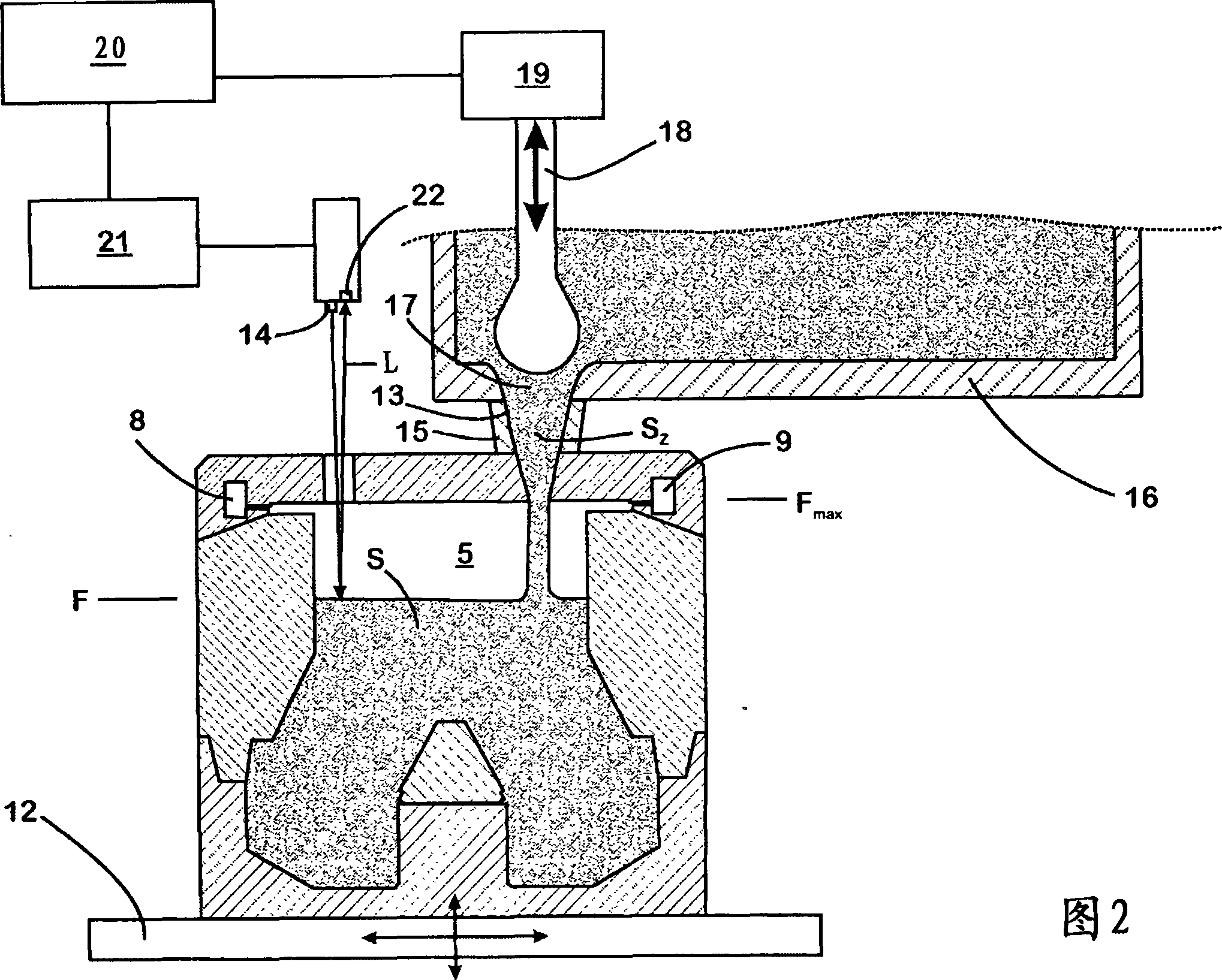

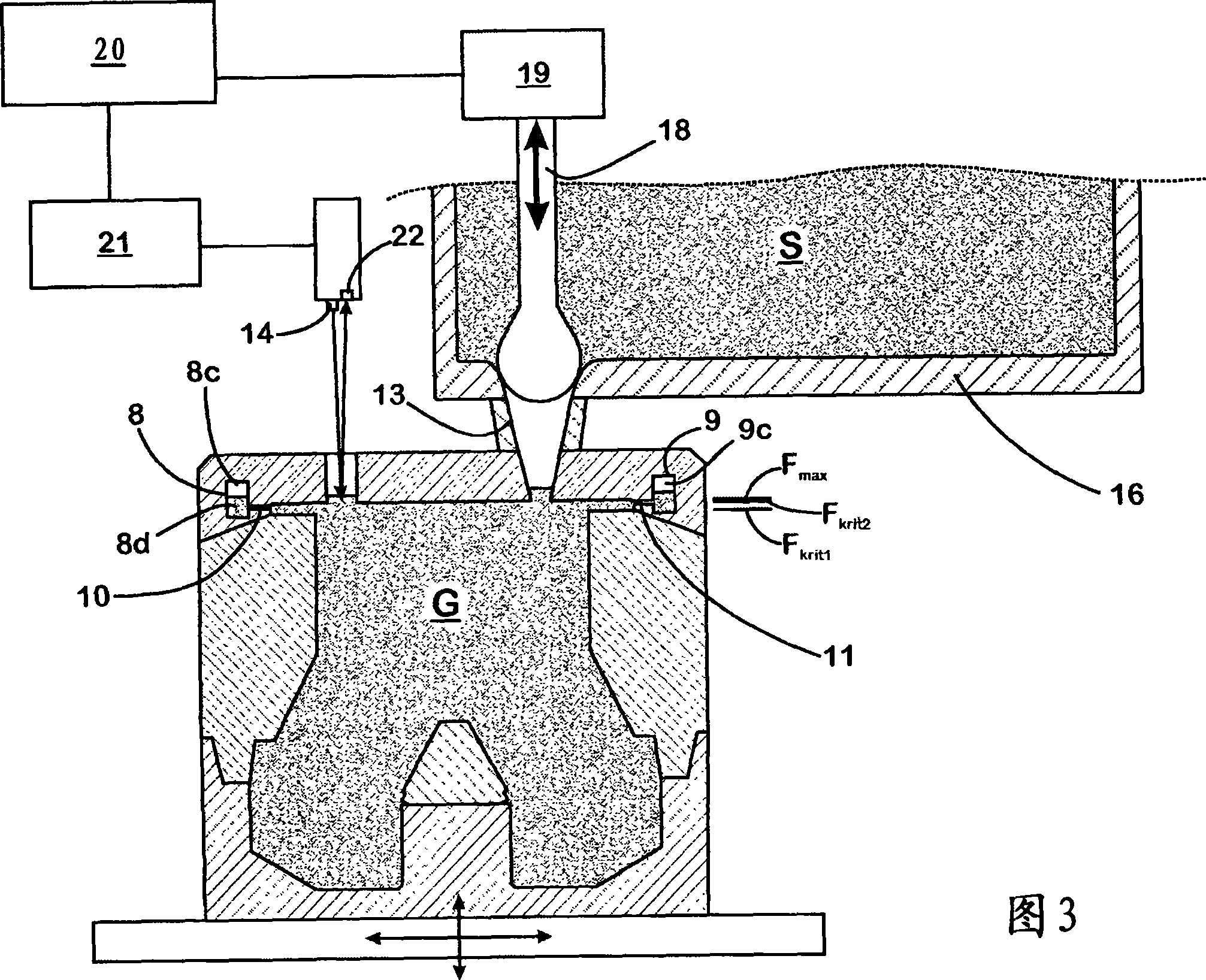

[0031] The casting mold 1 is composed of a plurality of side mold elements 2, 3, a bottom surface element and a mold cover element 4 as a mold core assembly (Kernpaket), the mold cover element 4 is arranged on the casting mold in the casting position shown in the figures and is placed on it. The upper side of the cavity 5 covers the cavity 5 surrounded by the mold elements 2 , 3 , 4 . The mold elements 2 , 3 , 4 are produced from a mold material mixed with molding sand and a binder and are destroyed when the casting G formed in the mold cavity is demolded. The casting G may relate, for example, to a cylinder block for an internal combustion engine.

[0032] Formed in the mold cover element 4 of the casting mold 1 is a funnel-shaped sprue opening 6 that tapers in the direction of the cavity 5 and opens into it, and a cylindrical inspection hole 7 is formed, which likewise extends straight from the top surface of the mold cover element 4 . into cavity 5.

[0033] The mold cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com