Composite bar energy converter cleaning machine

A technology of transducers and composite rods, which is applied in the field of cleaning machines, can solve problems such as oil stains, dirt, and dust that are difficult to remove, reduce operation quality, and small bandwidth, and achieve good cleaning operation quality, wide operating frequency range, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Embodiments of the invention will be described in detail below with reference to the accompanying drawings

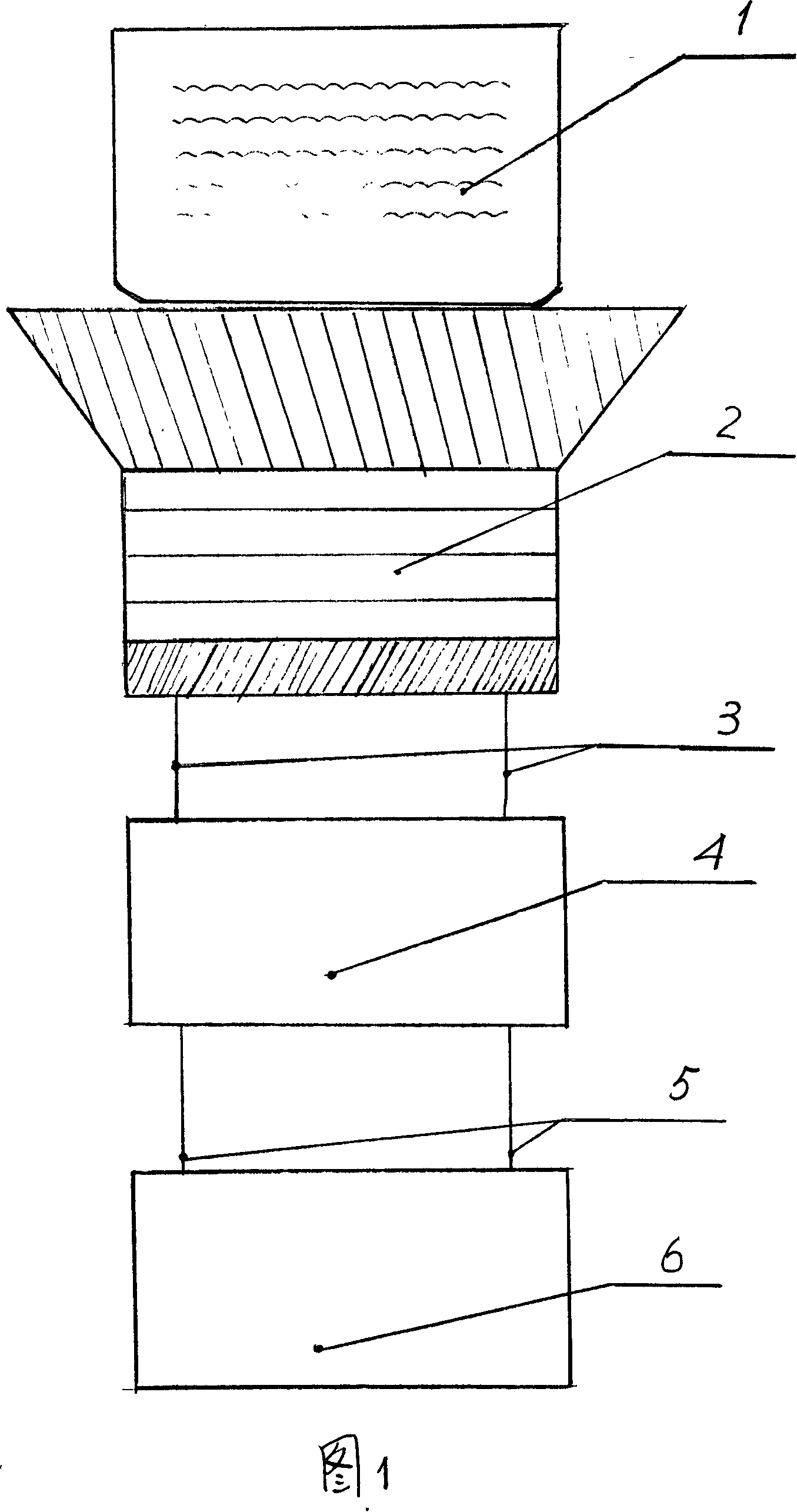

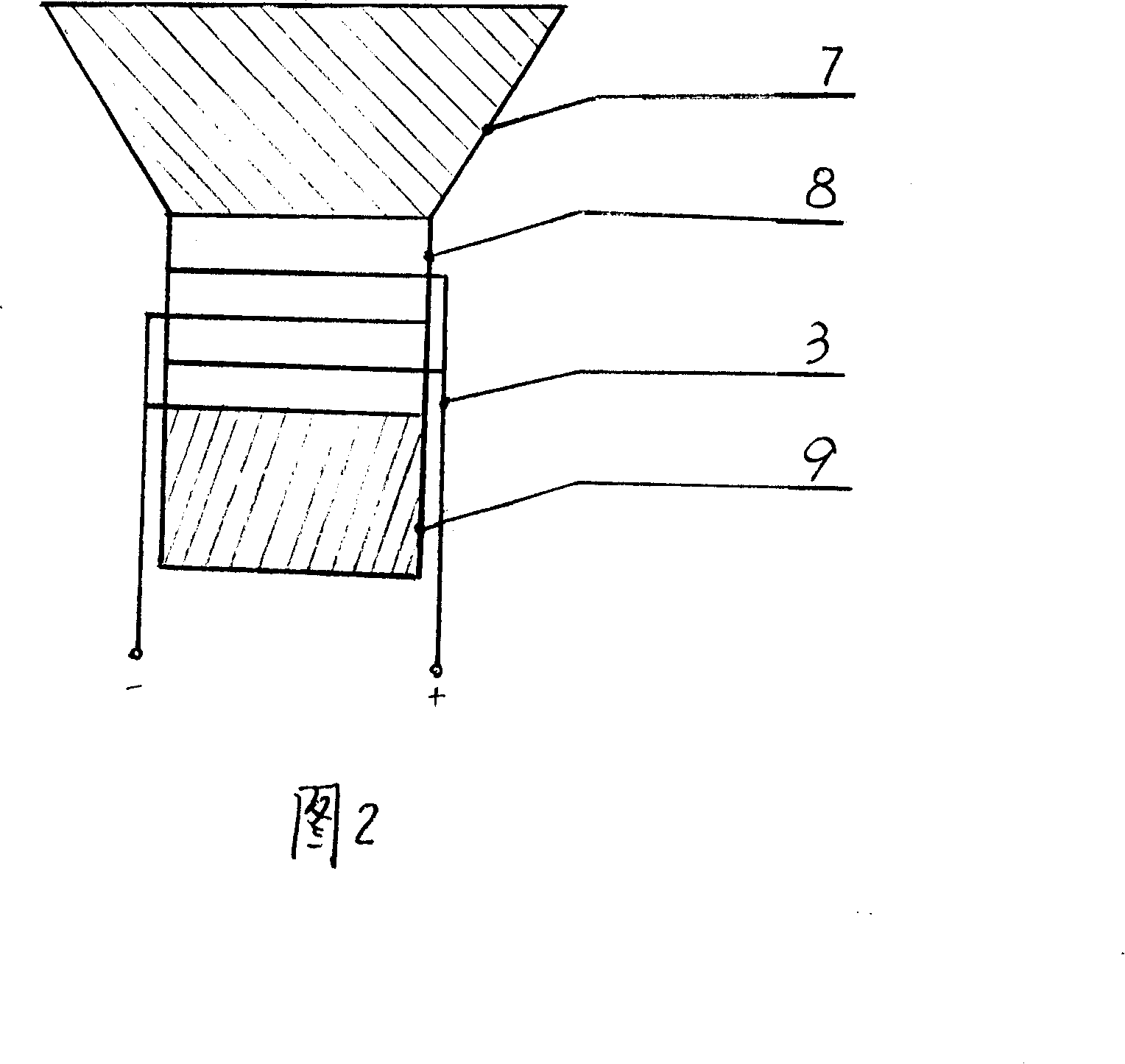

[0010] The composite rod transducer cleaning machine includes a liquid container 1, a power amplifier 4 and a signal source 6. The liquid container 1 is assembled on the upper part of the composite rod transducer 2, and the wire 3 and the wire 5 respectively connect the composite rod transducer 2 and the power amplifier 4. And the power amplifier 4 is connected with the signal source 6 . The composite rod transducer 2 is composed of a duralumin front cover 7, a piezoelectric ceramic stack 8 and a steel back cover 9. The hard aluminum front cover 7 and the steel back cover 9 are respectively assembled on the piezoelectric ceramics. On the upper and lower end surfaces of the stack 8 , the wires 3 are respectively connected to the positive and negative electrical contacts of the piezoelectric ceramic stack 8 .

[0011] When cleaning parts, put the cleaning liquid i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com