Automatic sewing device

A driving device and sewing technology, applied in sewing machine control devices, sewing equipment, sewing machine components, etc., can solve the problems of complex structure, reduce production efficiency, increase the workload of operators, etc., achieve convenient operation, high production efficiency, reduce The effect of the process and time of folding and flipping the fabric

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

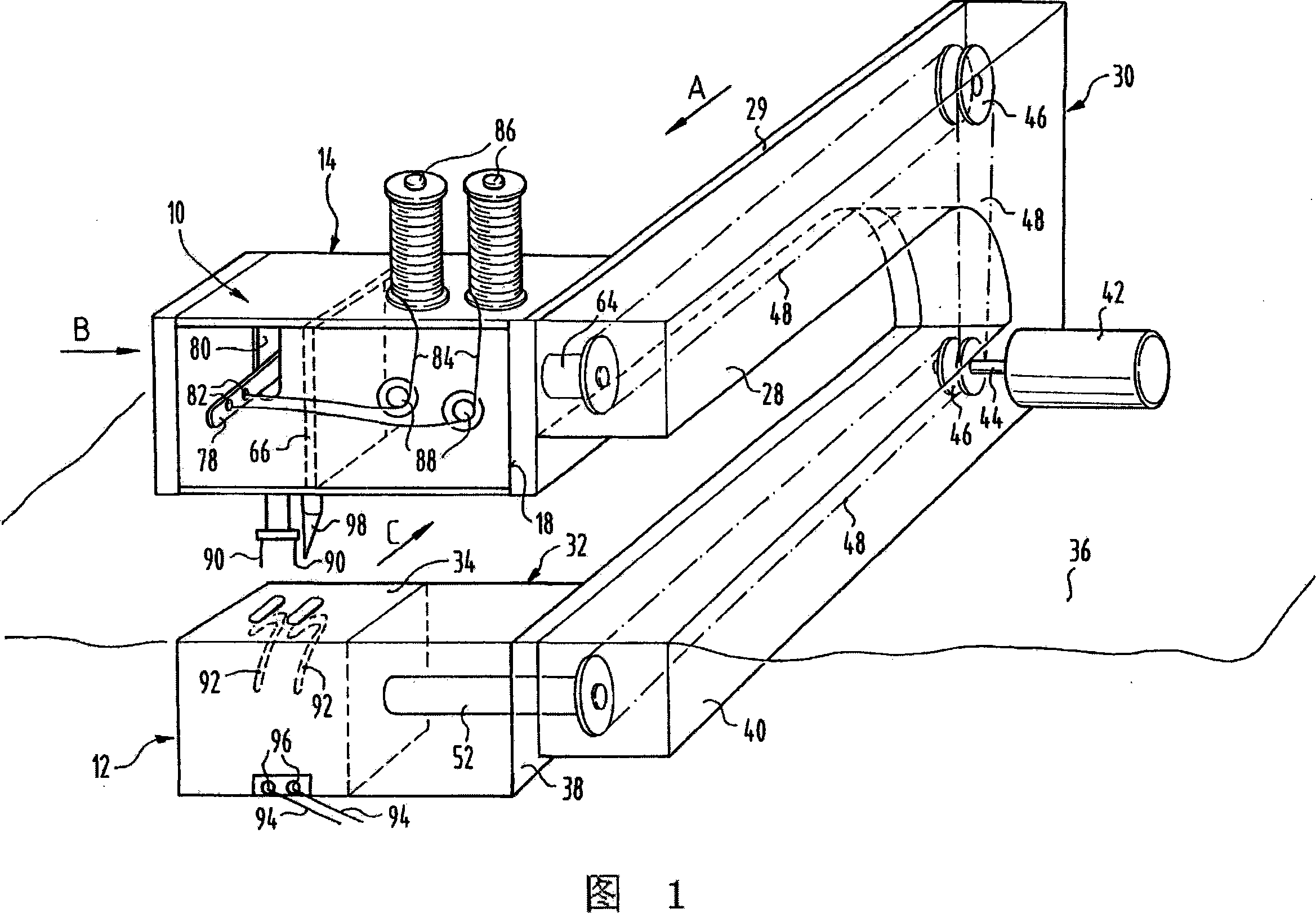

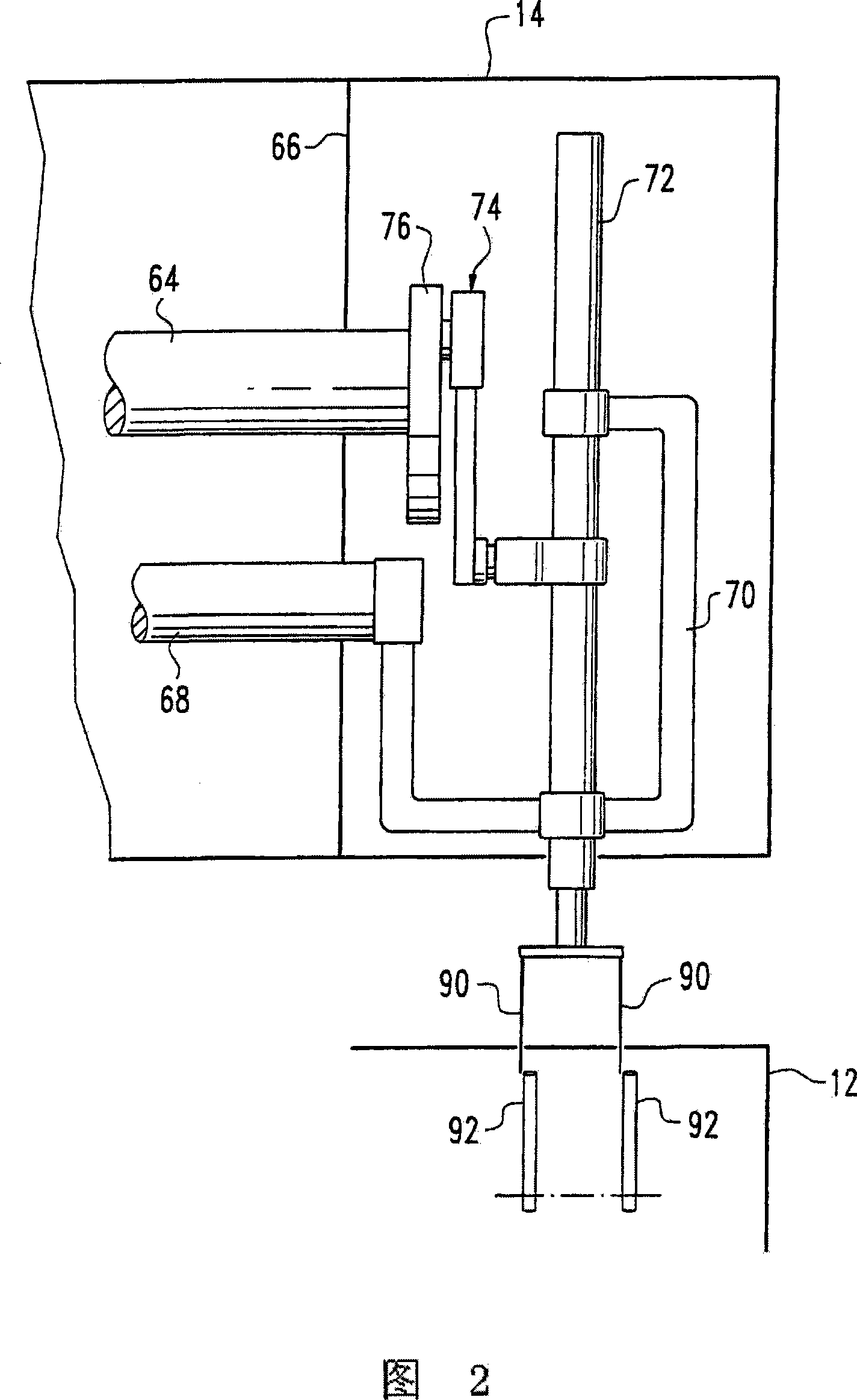

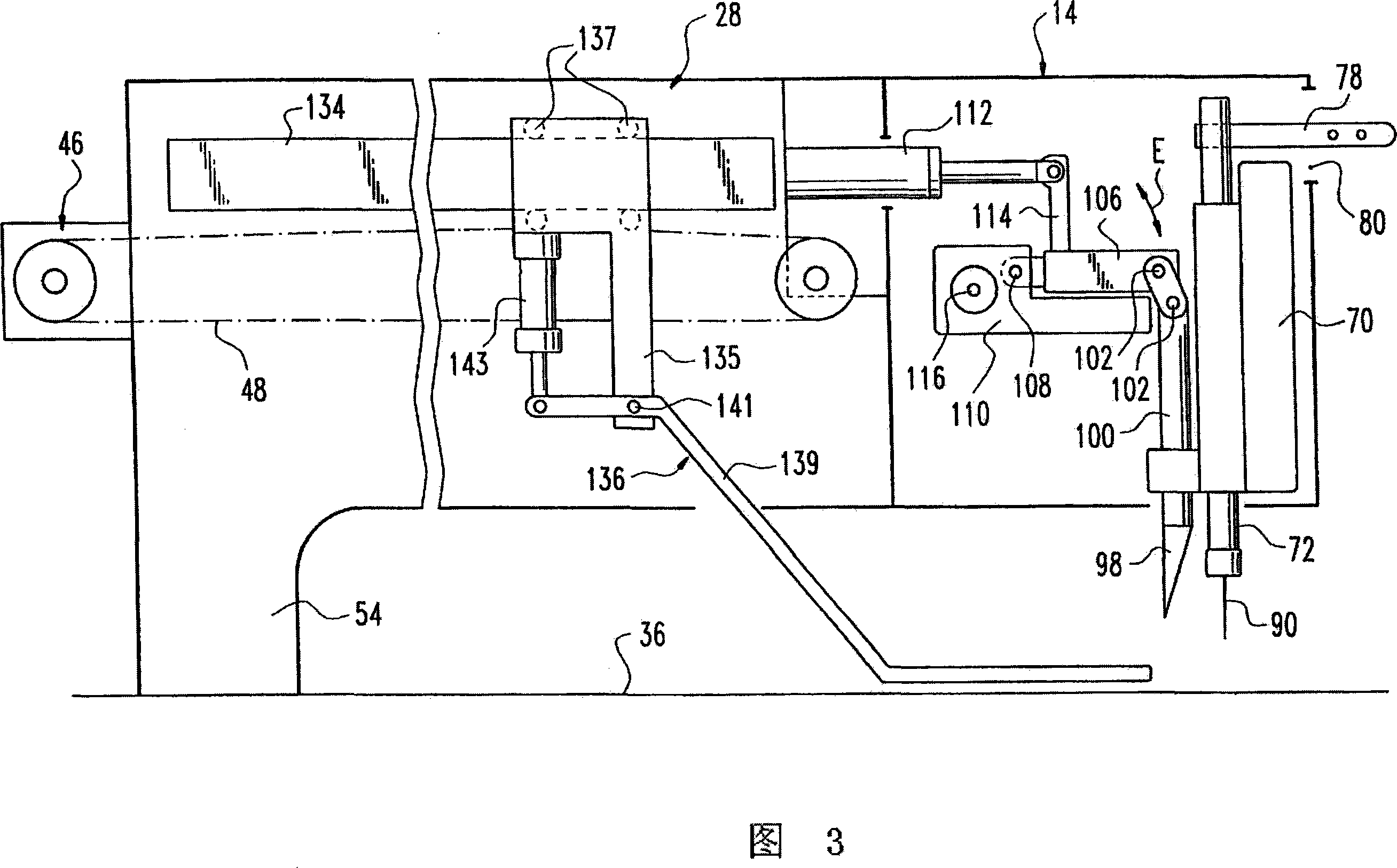

[0036] As shown in Figure 1, this automatic sewing device comprises superstructure 10 and substructure 12, and superstructure 10 comprises a rectangular upper housing 14, and this upper housing 14 has six sides, and wherein sidewall is designed as upper mounting surface 18, whereby the upper shell 14 is fixed on the upper arm 28 of the C-shaped bracket 30. A groove-shaped opening 80 is also formed on the upper housing 14 , and the thread take-up rod 78 protrudes from the groove-shaped opening 80 . The lower structure 12 also has a rectangular lower casing 32. There is a needle plate 34 on the lower casing 32, and the needle plate 34 is flush with the cloth table 36. The lower structure 12 also relies on the lower casing 32...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com