Full-frequency sound absorption component and making method

A production method and sound-absorbing technology, which is applied to building components, sound insulation, etc., can solve problems such as the inability to achieve full-band sound absorption, and achieve good absorption effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

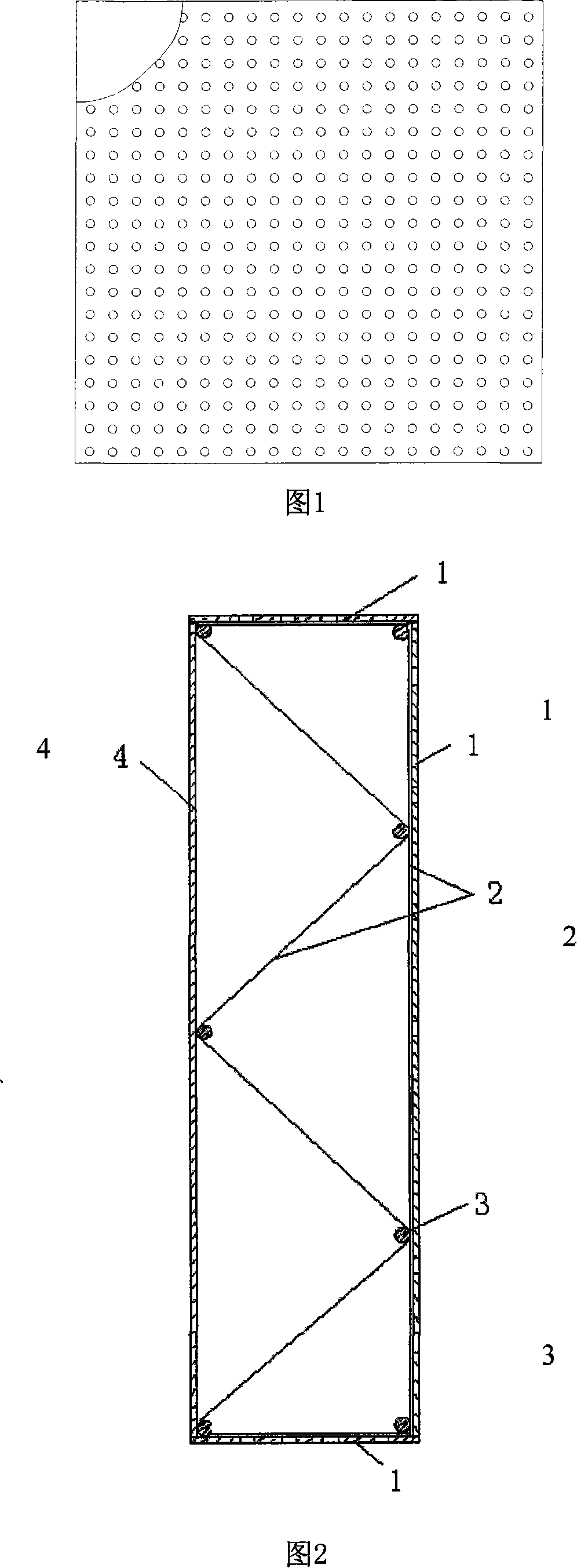

[0019] A full-frequency sound-absorbing component according to the present invention is mainly composed of a surface-perforated sound-absorbing panel 1 , a micro-perforated sound-absorbing membrane (thin plate) 2 , steel bars 3 and a protective panel 4 . The micro-perforated sound-absorbing film (thin plate) 2 is made of PVC material, the surface-perforated sound-absorbing board 1 is made of aluminum plate, the guard plate 4 is made of aluminum plate, and the steel bar 3 acts as a keel support.

[0020] The micro-perforated sound-absorbing film (thin plate) 2 respectively cross-wraps the steel bars 3 on both sides along the direction of the fold line, effectively increasing the sound-absorbing area. Then wrap a circle along the surface of the perforated sound-absorbing panel, thus forming a double-layer micro-perforated sound-absorbing film (sheet) resonant sound-absorbing structure, and the rear resonant cavity of each layer of micro-perforated sound-absorbing film (sheet) is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com