Sample feeding system, anticollision device and anti-collision method

An anti-collision device and anti-collision technology, applied in the field of medical and chemical industry, can solve problems such as the collision of the sample adding system, and achieve the effects of ensuring the safety of people and equipment, easy detection process, and simple mechanical structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

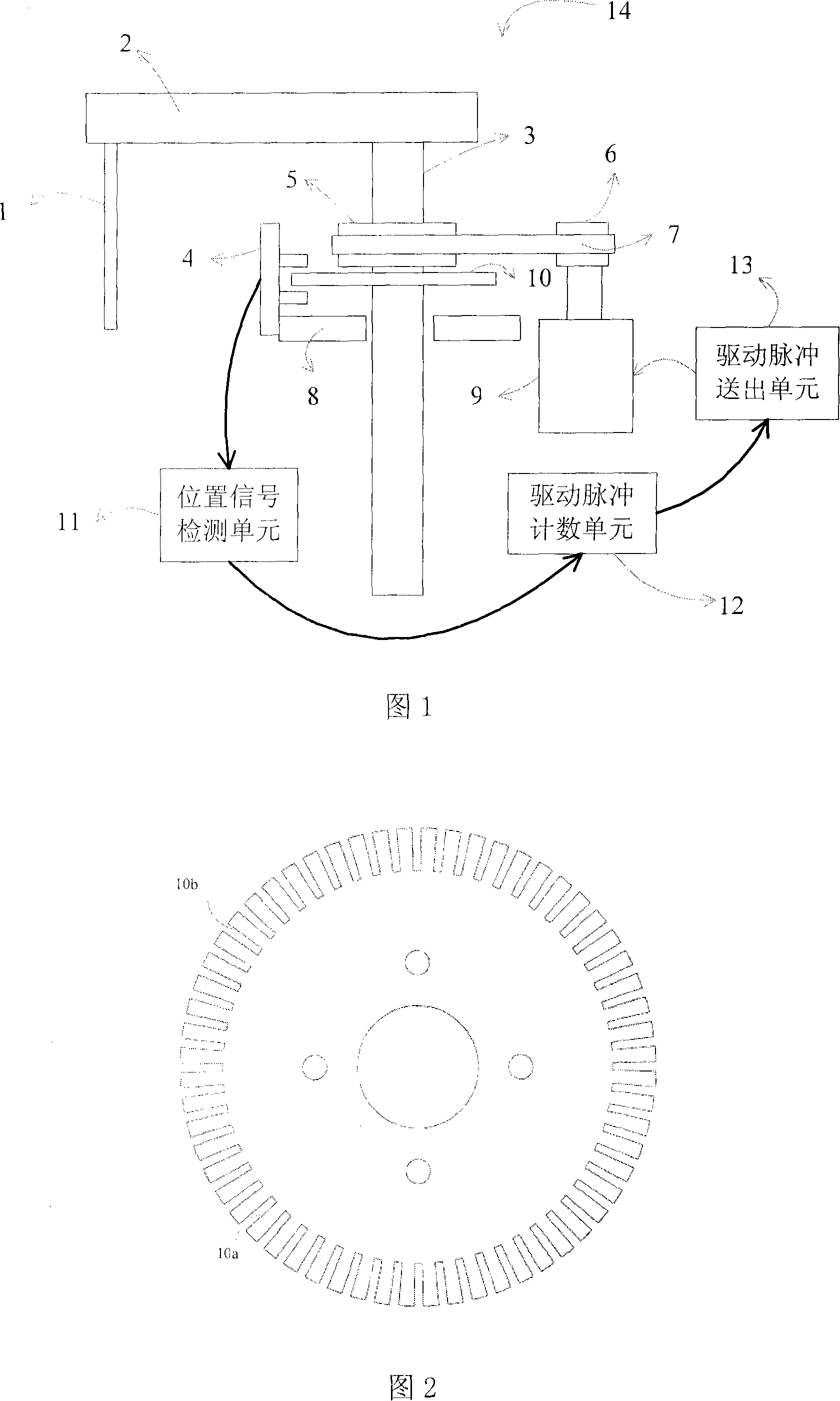

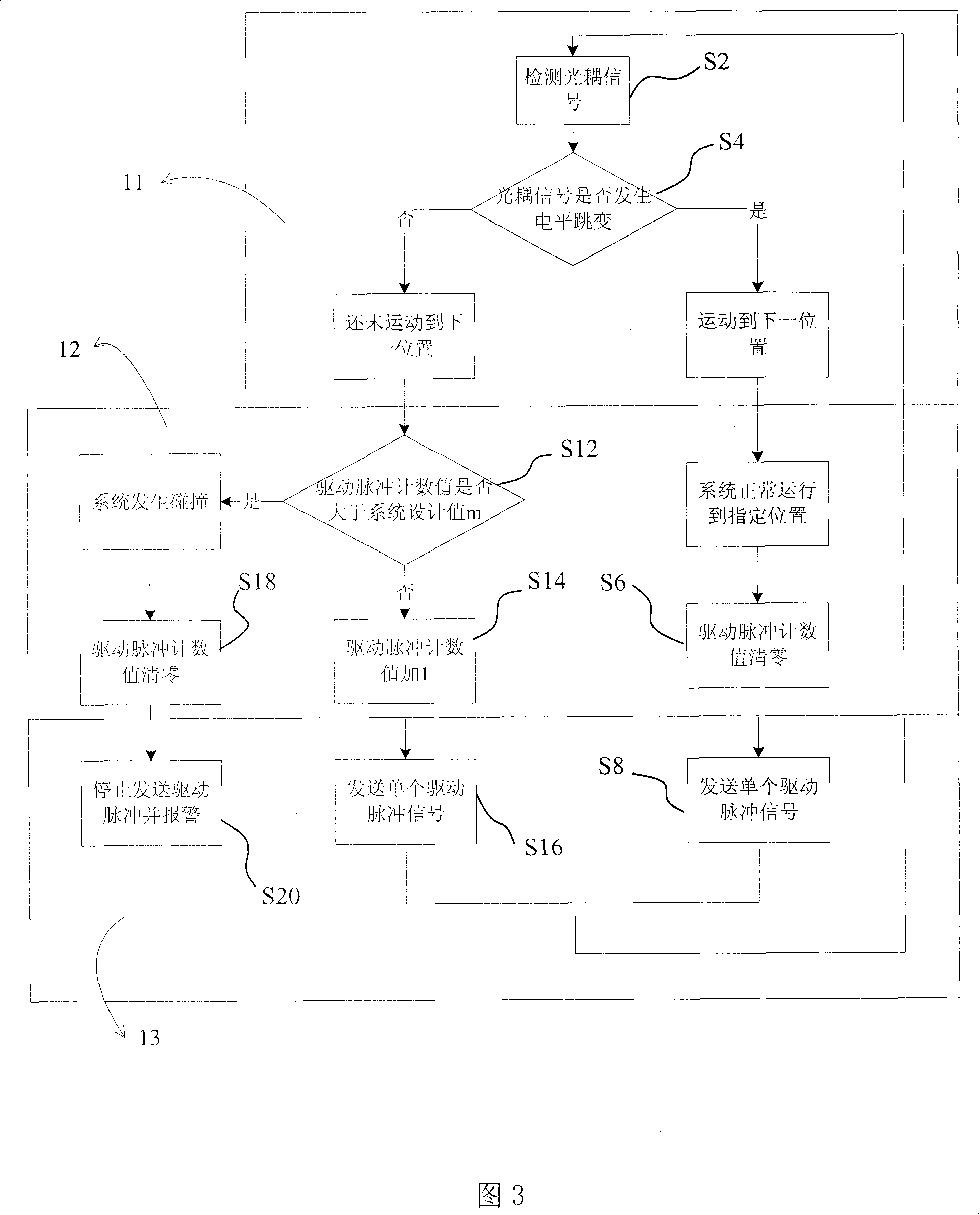

[0037] Embodiment 1. This embodiment is an application of the present invention in a rotary sample feeding system. The moving mechanism is a rotating mechanism, including a rotating shaft. The overall structure of the sample feeding system 14 is shown in Figure 1, the driving motor 9 is connected to the small pulley 6 and drives it to rotate, the small pulley 6 is connected to the large pulley 5 through the timing belt 7, and the rotational motion is transmitted to the large pulley 5 , the large pulley 5 drives the rotating shaft 3 and the code disc 10 to move synchronously. The probe 1 is connected with the rocker 2, and the rocker 2 connected thereto is driven by the rotating shaft 3 to rotate the probe 1 to a designated position. The code disc 10 is a circular disc, and the edge of the code disc 10 is equidistantly provided with light-transmitting gaps 10a, and the light-transmitting gaps 10a can be bar-shaped or tooth-shaped apertures, as shown in Figure 2, and can also be...

Embodiment 2

[0046] Embodiment 2, the present invention can also be applied in a linear motion sample adding system, the moving mechanism is a linear motion mechanism, the preferred solution is that the optical coupler is fixed on the moving mechanism and moves with the moving mechanism, the code disc is a rectangular disc, and is The accessories fixed on the moving track of the moving mechanism do not move with the moving mechanism, and one edge of the code disc is parallel to the moving track of the moving mechanism, so that the code disc penetrates the light gap into the detection position of the optocoupler. The position signal detection unit, the driving pulse counting unit and the driving pulse sending unit can be the same as those in the first embodiment, and have the same anti-collision function as the first embodiment.

[0047] It should be noted that the above-mentioned code wheel with a light-transmitting gap can be replaced by a mark wheel with uniformly distributed micromirrors...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com