Design of ultra-applanation fuel battery engines air conveying device

An air conveying device and fuel cell technology, which is applied to fuel cell components, fuel cells, fuel cell additives, etc., can solve the problems of limited installation space, large volume, and inability to install, and achieve space saving and small volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

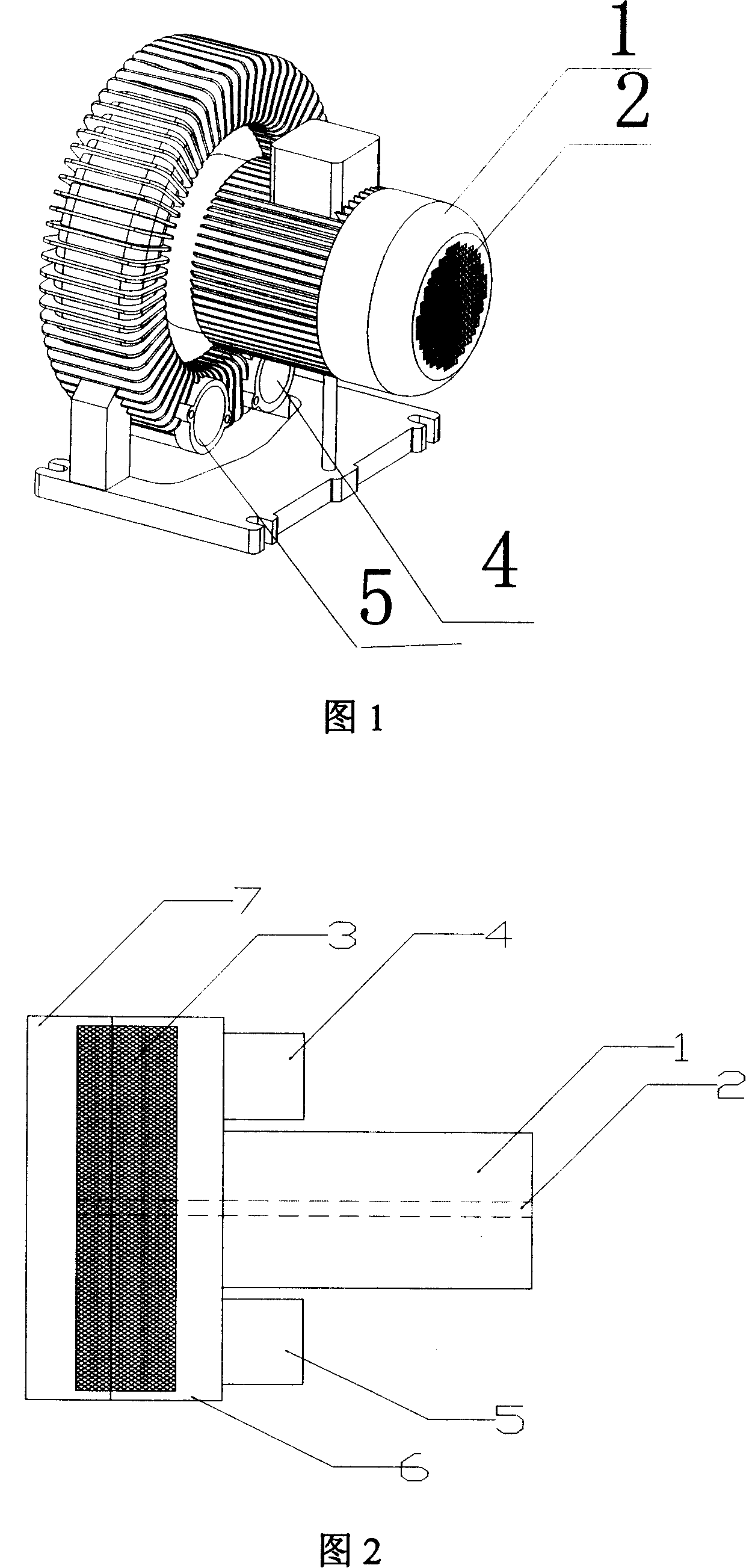

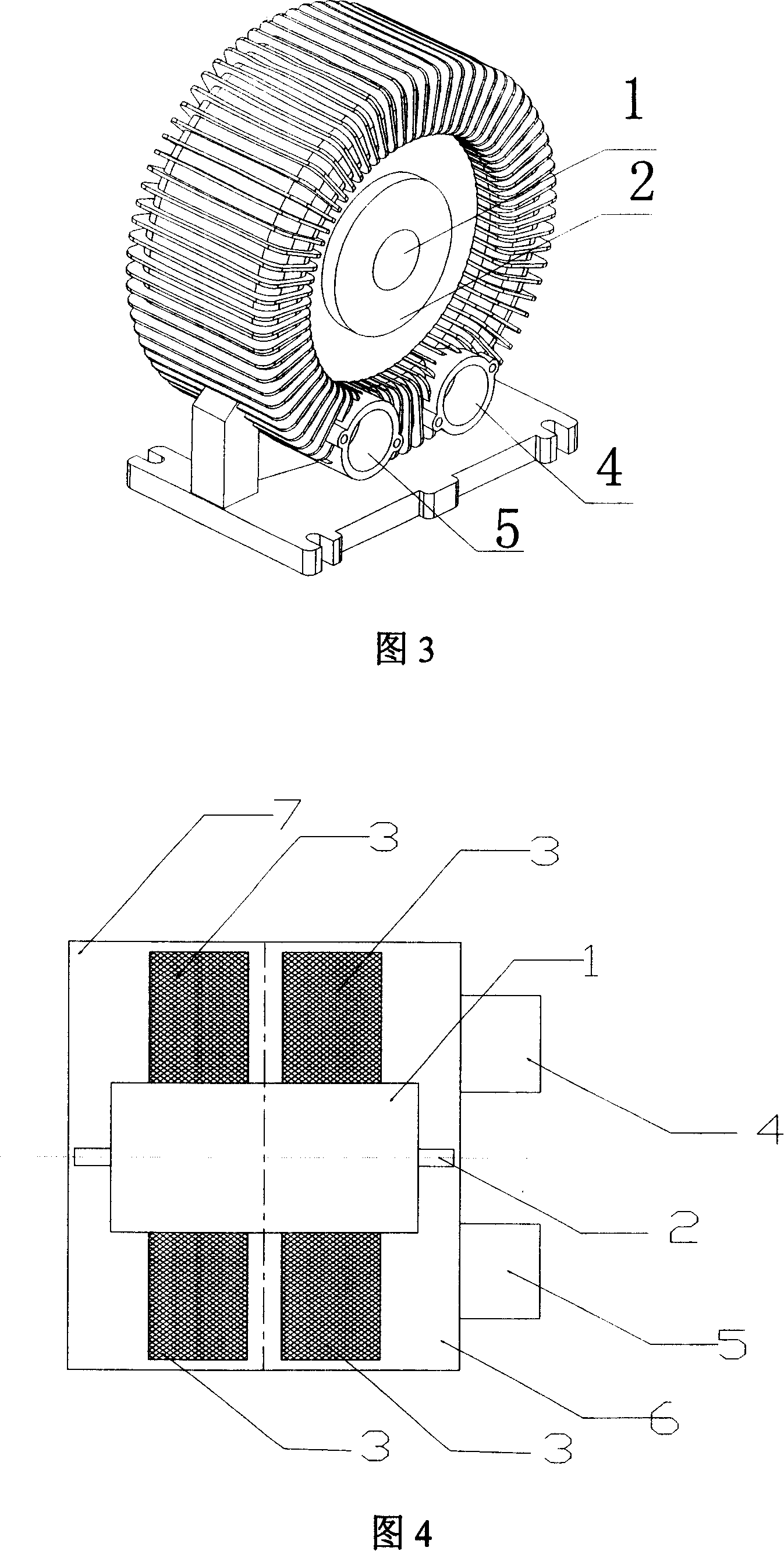

[0029] As shown in Figures 3 and 4, the design of an ultra-flat fuel cell engine air delivery device includes the outer rotor 1 of the motor, the central stator 2 of the motor, the impeller 3 of the fan, the air suction port 4, the air outlet 5, and the upper part of the fan. The drum 6, the lower drum 7 of the fan, the central stator 2 of the motor is fixed on the upper and lower drums 6, 7 of the fan, and the outer rotor 1 of the motor is directly provided with an impeller 3, so that the motor and the fan drum are integrated, The height of the whole air conveying device is the sum of the heights of the upper and lower drum discs of the fan, and the air suction port 4 and the air outlet port 5 are arranged on the drum disc.

[0030] The impeller can be provided with 1 to 4 as required, and this embodiment is provided with 2; the material of the impeller includes metal and plastic, and this embodiment uses engineering plastics, such as polytetrafluoroethylene plastic; the sucti...

Embodiment 2

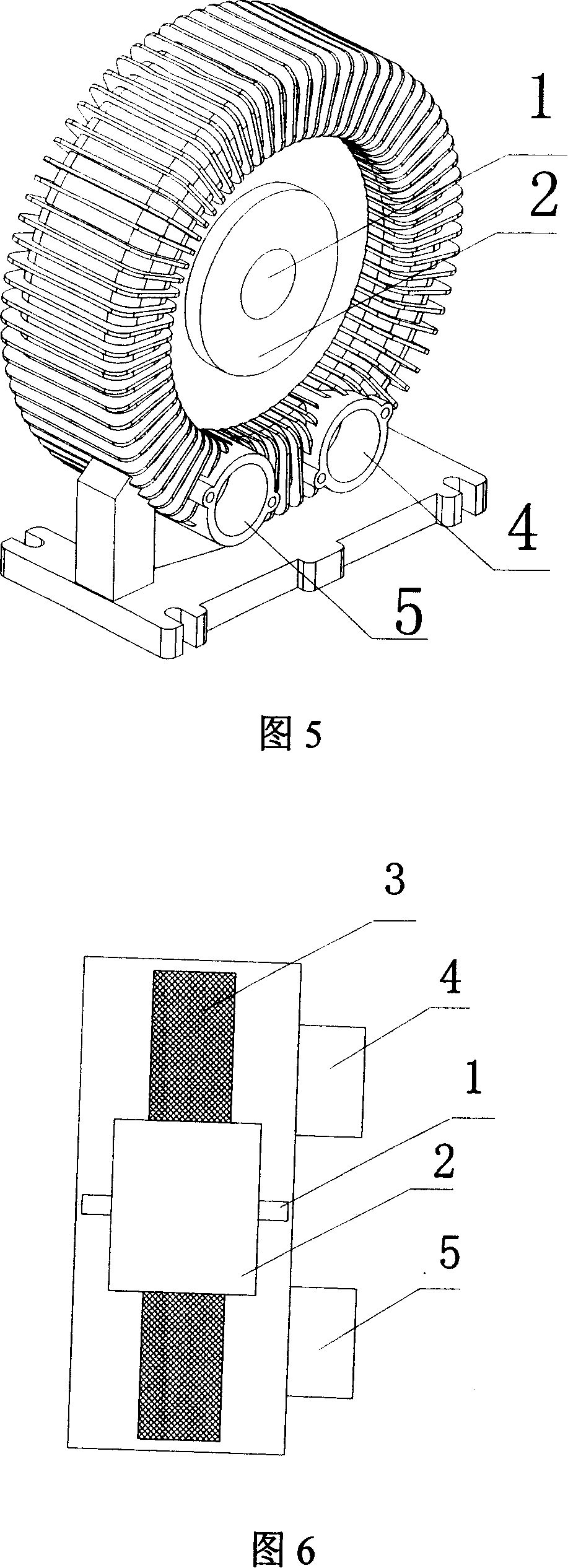

[0032] As shown in Figures 5 and 6, the design of an ultra-flat fuel cell engine air delivery device includes the outer rotor 1 of the motor, the central stator 2 of the motor, the impeller 3 of the fan, the air suction port 4, the air outlet 5, and the upper part of the fan. The drum 6, the lower drum 7 of the fan, the central stator 2 of the motor is fixed on the upper and lower drums 6, 7 of the fan, and the outer rotor 1 of the motor is directly provided with an impeller 3, so that the motor and the fan drum are integrated, The height of the whole air conveying device is the sum of the heights of the upper and lower drum discs of the fan, and the air suction port 4 and the air outlet port 5 are arranged on the drum disc.

[0033] The impeller can be provided with 1 to 4 as required, and one is provided in this embodiment; the material of the impeller includes metal and plastic, and metal material is used in this embodiment; The same side or the different side of the disc, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com