Heat pipe type solar thermal-collecting tube

A solar collector tube and heat pipe type technology, applied in the directions of solar collectors, solar thermal energy, solar thermal power generation, etc., can solve the problems of burst tubes, large circular cavity space, inability to heat the heat conduction medium, etc., to improve the effective utilization rate, Fast hot start and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

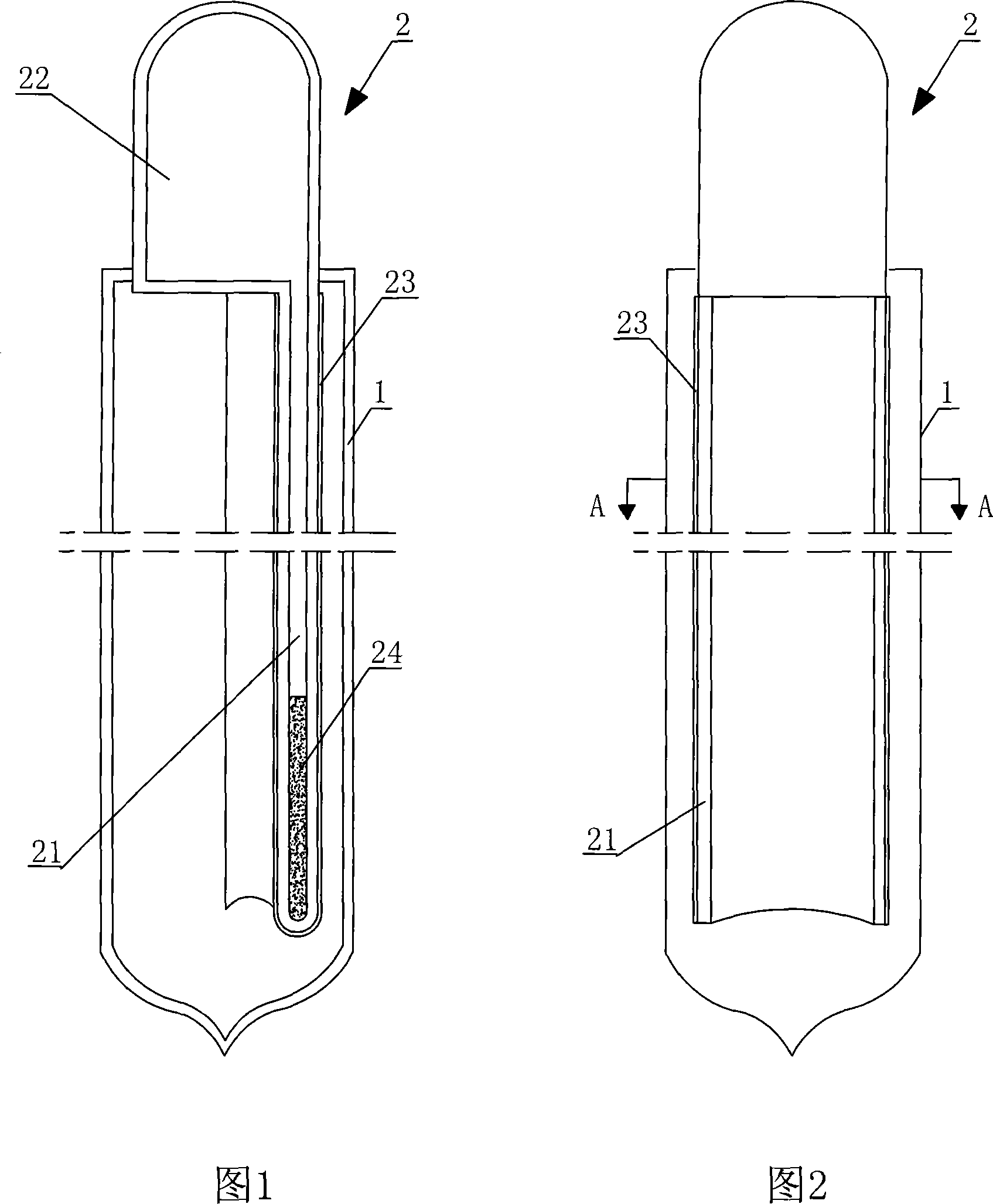

[0042] Referring to Fig. 1-3, a heat pipe type solar collector tube is composed of an outer tube 1 and an inner heat pipe 2, the inner heat pipe 2 is composed of a heat absorbing part 21 and a heat releasing part 22, and the inner heat pipe 2 The heat-absorbing part 21 of the inner heat pipe 2 is arranged in the outer casing 1, and the cross-section of the heat-absorbing part 21 of the inner heat pipe 2 is a circular arc-shaped double-layer structure provided with a hollow inner cavity, and the heat-releasing part 22 of the inner heat pipe 2 is clamped It is located outside the outer casing 1, and the joint between the inner heat pipe 2 and the outer casing 1 is sealed. The outer surface of the heat-absorbing part 21 of 2 is coated with a solar absorbing coating 23, and the inner cavity of the inner heat pipe 2 is provided with a heat-conducting medium 24.

[0043] The heat absorbing part 21 of the inner heat pipe 2 has a double-layer structure with a circular arc-shaped cross...

Embodiment 2

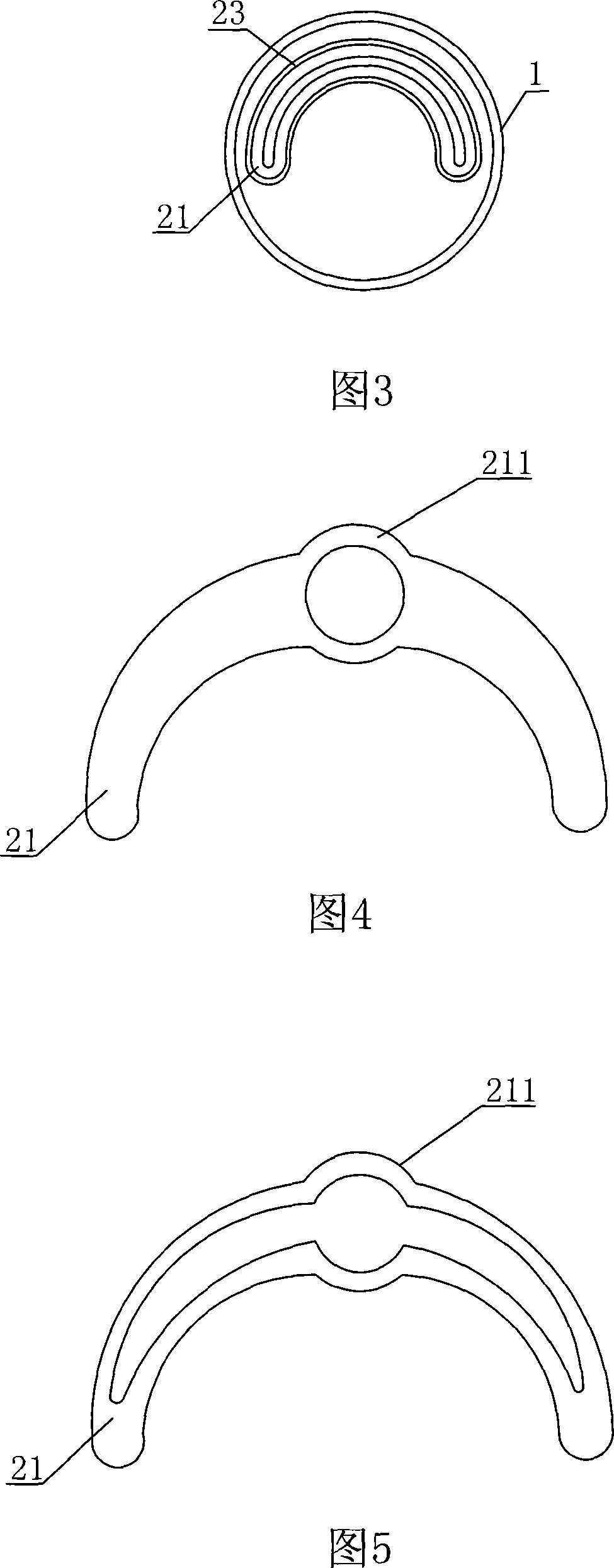

[0051] Referring to shown in Fig. 4, a kind of heat pipe type solar collector tube, it differs from Embodiment 1 in that:

[0052] The heat absorbing part 21 of the inner heat pipe 2 is provided with a double-layer structure with a circular arc-shaped cross-section and a hollow inner cavity, and a hollow inner cavity 211 with a circular cross-section is provided.

[0053] The heat absorbing portion 21 of the inner heat pipe 2 has an arc-shaped cross section and a double-layer structure with a hollow inner cavity, and the distance between inner walls is 0.1 mm.

[0054] The heat release portion 22 of the inner heat pipe 2 has a length of 5 cm.

[0055] The shape of the inner chamber cross-section of the heat releasing part 22 of the inner heat pipe 2 is arc shape.

[0056] The shape of the cross-section of the outer sleeve 1 is a garden arc.

Embodiment 3

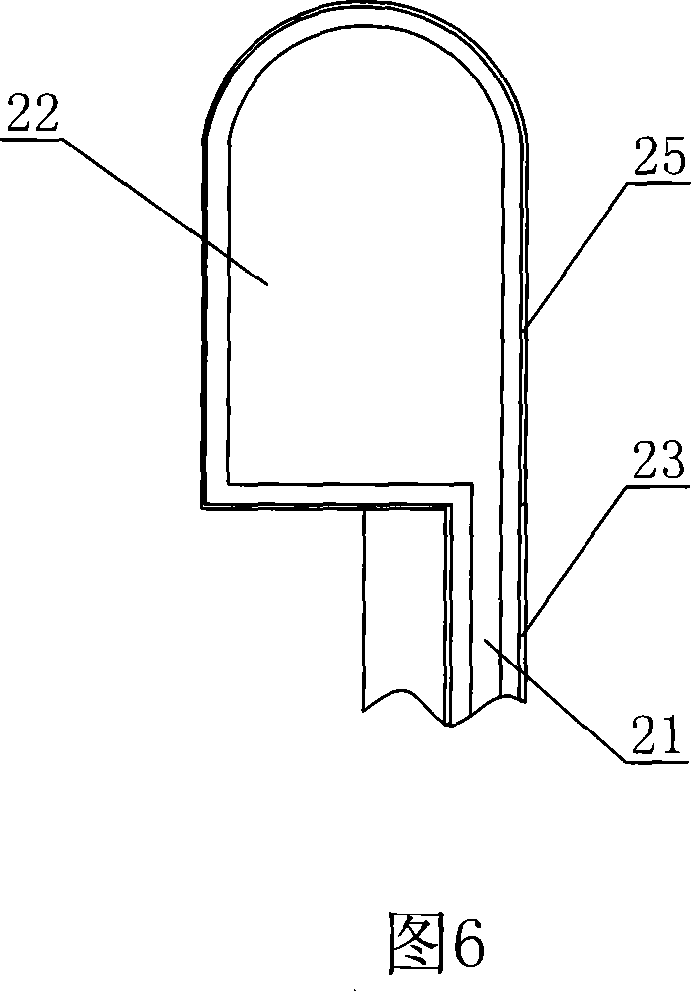

[0058] Referring to Fig. 5-6, a kind of heat pipe type solar collector tube differs from Embodiment 1 in that:

[0059] The cross-section of the heat absorbing portion 21 of the inner heat pipe 2 may be a combination of a hollow arc-shaped inner cavity and a hollow circular inner cavity.

[0060] The material of the inner heat pipe 2 is plastic.

[0061] The heat conducting medium 24 is a composite inorganic superconducting heat medium.

[0062] The surface of the inner cavity of the heat absorbing part 21 of the inner heat pipe 2 is coated with a solar absorbing coating 24 .

[0063] The outer surface of the heat release part 22 of the inner heat pipe 2 is coated with an anti-scaling thermal conductive coating 25 .

[0064] The heat-absorbing part 21 of the inner heat pipe 2 has an arc-shaped cross-section and a double-layer structure with a hollow inner cavity, and the distance between inner walls is 3 mm.

[0065] The heat release portion 22 of the inner heat pipe 2 has ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com