Drilling fluid high-temperature high pressure multifunctional dynamic evaluation tester

A high-temperature, high-pressure, multi-functional technology, applied in the fields of instruments, scientific instruments, earth-moving drilling, etc., can solve the problems of wrong test methods, cumbersome operation steps, unsatisfactory equipment and other problems, and achieve continuously adjustable shear rate, convenient and convenient. cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

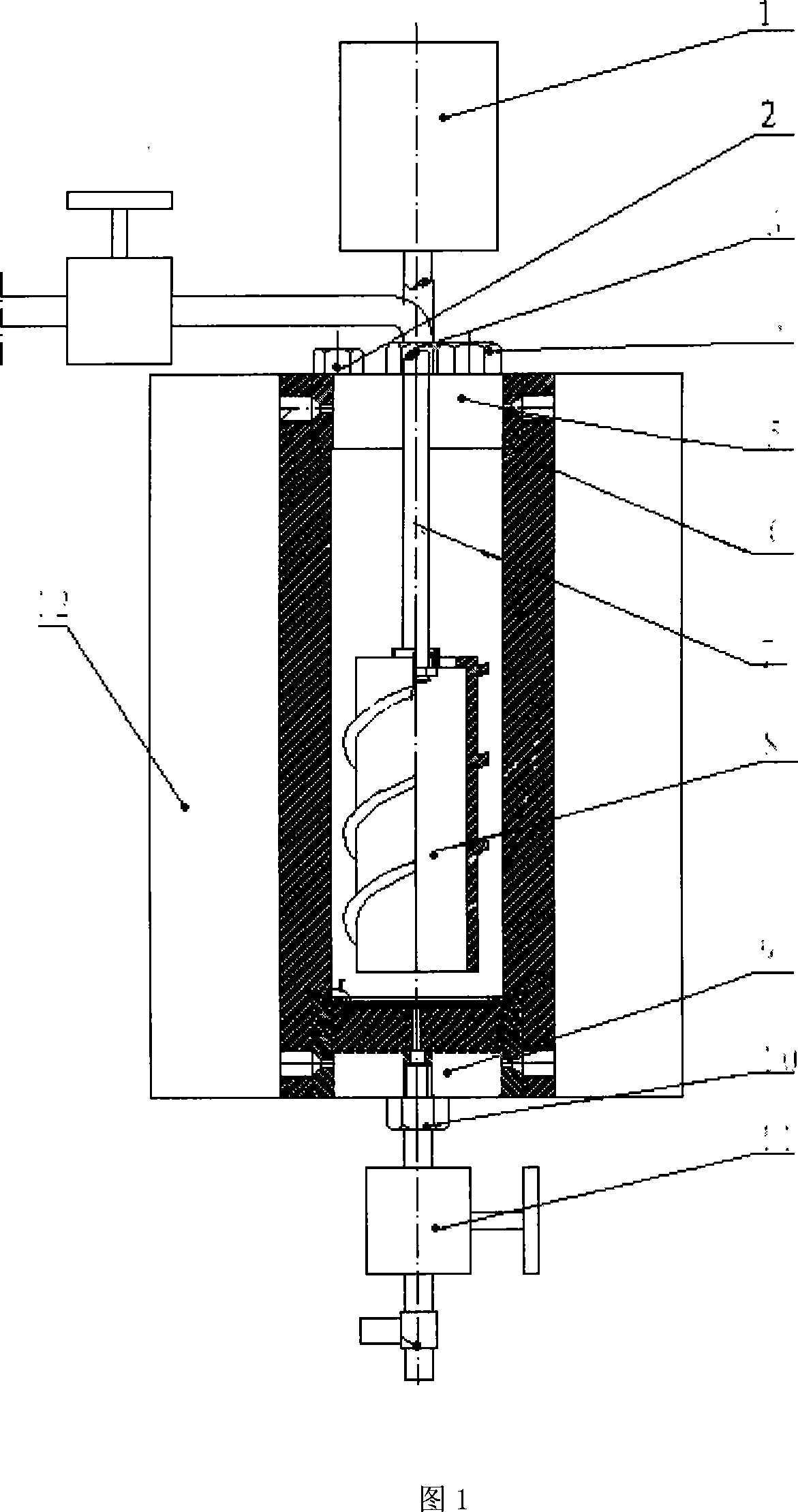

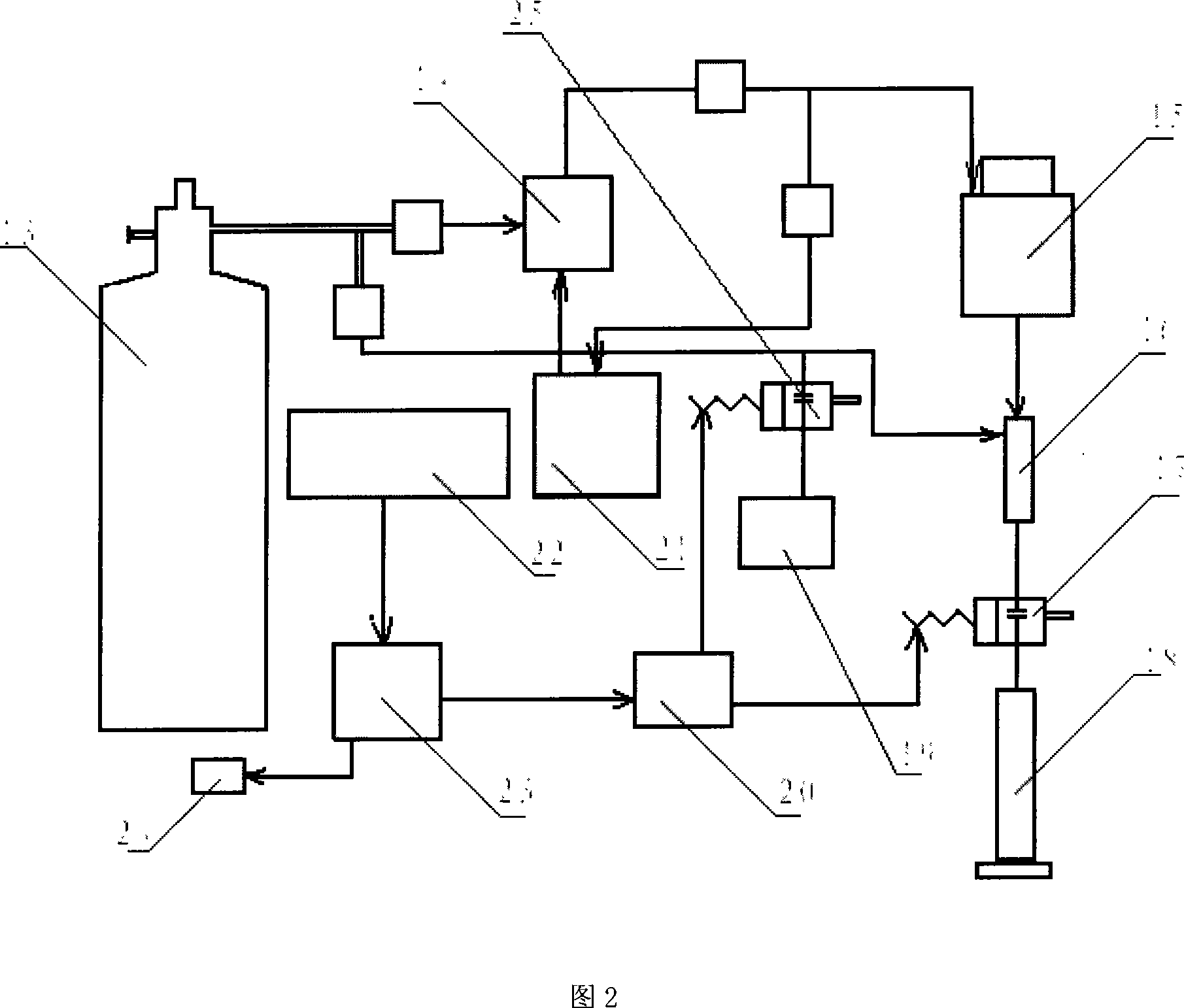

[0017] Drilling fluid high temperature and high pressure multifunctional dynamic evaluation test instrument, mainly composed of booster pump 14, test tank 15, condenser 16, solenoid valve 17, material storage tank 21, filtrate measuring cylinder 18, slurry tank 19, sensor 22, computer 23 and Composed of time controller 20, experimental tank 15 is mainly composed of tank body 12, magnetic transmission system 1, thermometer socket 2, booster hole joint 3, liquid filling hole joint 4, mud cup 6, stirring shaft 7, and mixing drum 8, The top of the test tank 15 is a magnetic transmission system 1, and the top cover of the test tank 15 is respectively provided with a thermometer jack 2, a booster hole joint 3, and a liquid filling hole joint 4. The center of the test tank 15 is a mud cup 6, and the top of the mud cup 6 is It is the upper cover 5 of the mud c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com