Antiseptic mixture and photoresist stripper composition

A technology of preservatives and mixtures, applied in the field of lithographic printing of printed circuit boards, can solve problems affecting product quality, corrosion of wiring materials, etc., and achieve excellent peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

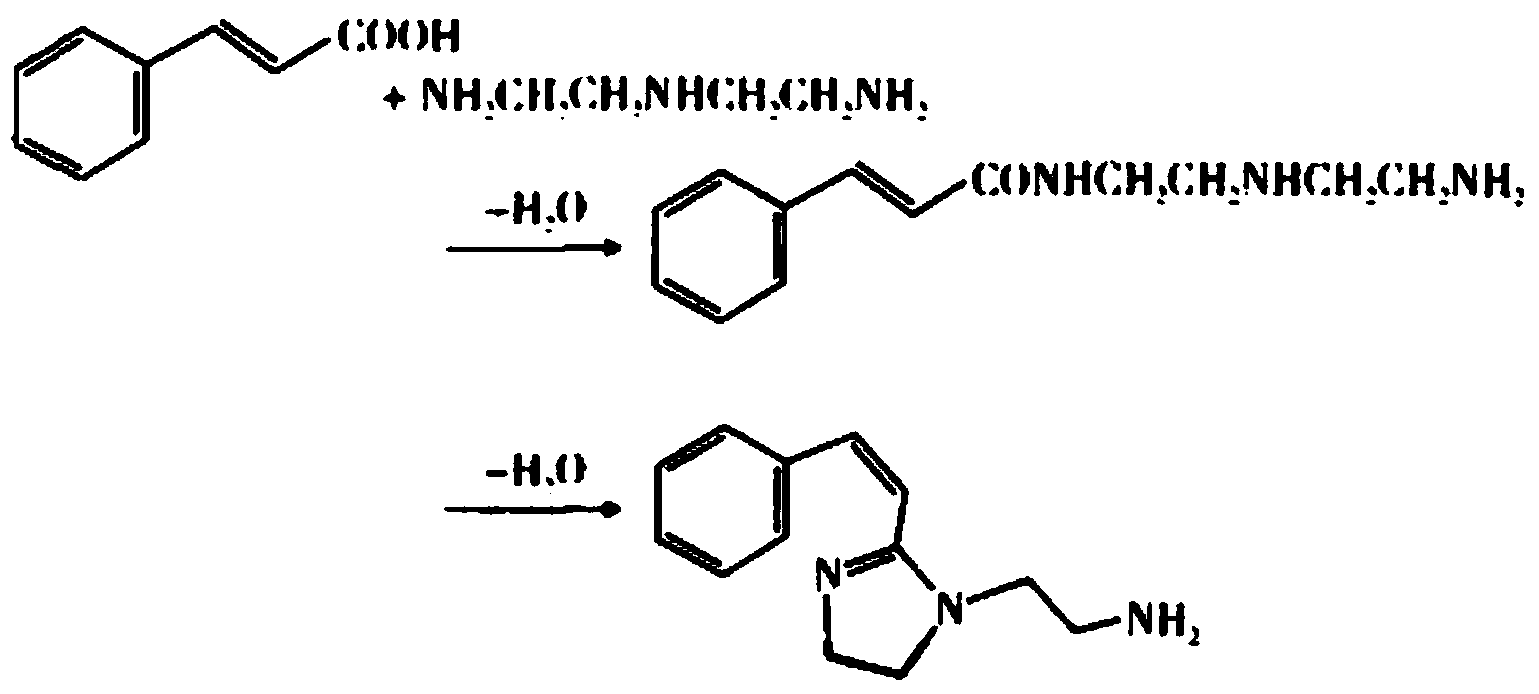

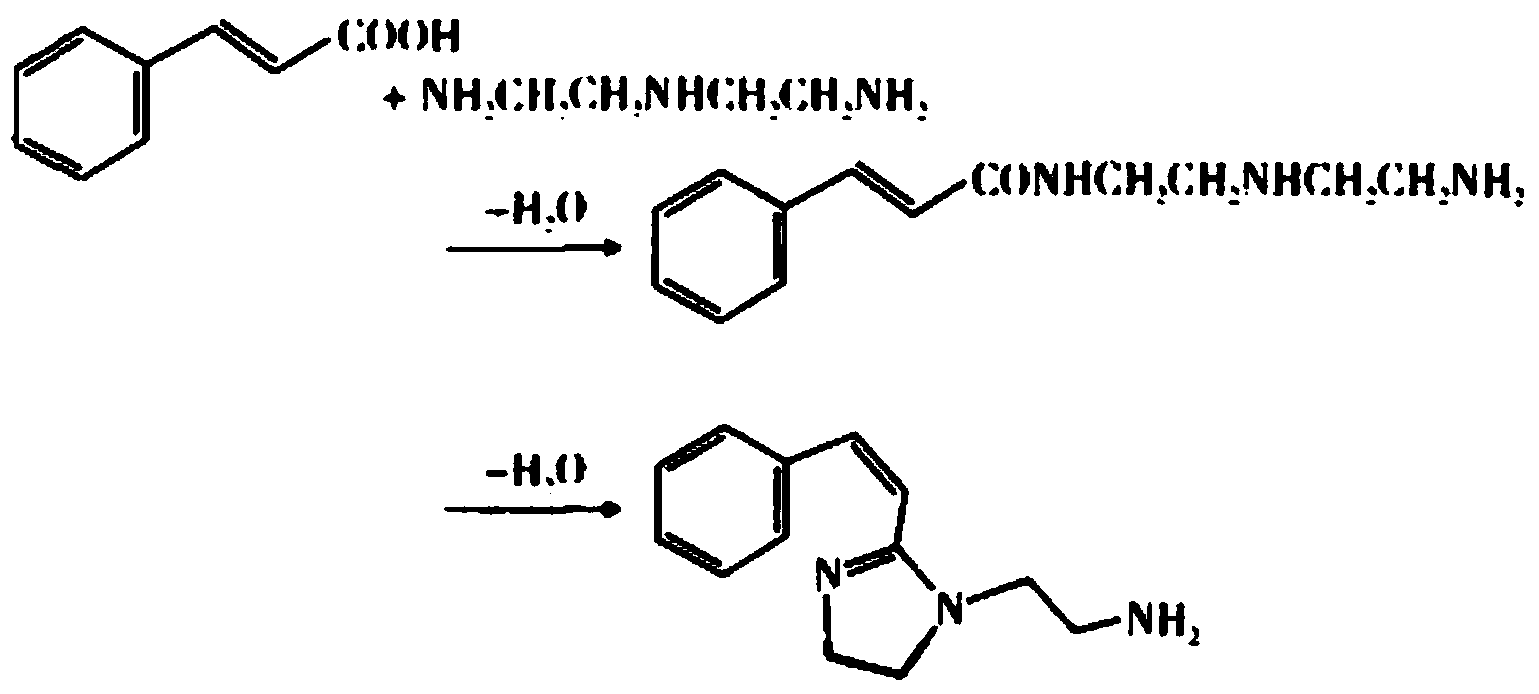

[0041] The preparation method of described cinnamyl imidazoline is specifically:

[0042] Put 10ml of analytically pure diethylenetriamine in a four-necked flask, raise the temperature to 150°C, add 3ml of analytically pure toluene dropwise, add 22g of analytically pure cinnamic acid, stir under nitrogen, and then heat up to 170°C to start acyl After reaction for 5 hours, the temperature was raised to 240°C to start cyclodehydration for 3 hours. After the reaction was completed, it was placed in a vacuum drying oven to dry to obtain cinnamyl imidazoline in a brown viscous shape. The reaction formula is as follows:

[0043]

[0044] The present invention also provides a preparation method of the above-mentioned photoresist stripper composition. The above-mentioned polyol mixture, the above-mentioned Mix the anticorrosion agent mixture, the above-mentioned organic amine and the above-mentioned deionized water, and stir evenly to obtain the product.

Embodiment 1

[0046] The preparation of embodiment 1 cinnamyl imidazoline

[0047] Put 10ml of analytically pure diethylenetriamine in a four-necked flask, raise the temperature to 150°C, add 3ml of analytically pure toluene dropwise, add 22g of analytically pure cinnamic acid, stir under nitrogen, and then heat up to 170°C to start acyl After 5 hours of reaction, the temperature was raised to 240° C. to start cyclodehydration for 3 hours. After the reaction was completed, it was placed in a vacuum oven to dry to obtain cinnamyl imidazoline in a brown viscous shape.

Embodiment 2

[0048] Embodiment 2 photoresist stripping agent 1

[0049] With 5g sorbitol, 10g xylitol, 5g tetramethylammonium hydroxide, 20g sodium methylate, 5g morpholine, 4g polyoxyethylene ether, 15gN-methyl-2-pyrrolidone, 4g cinnamyl imidazole prepared in Example 1 Phenylline, 6g of 2-methyl-5-dodecylisoxazole, 20g of monoethanolamine and 6g of ionized water were mixed and stirred evenly to obtain photoresist stripper 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com