Grating aligner

A collimator and grating technology, applied in the field of medical equipment, can solve the problems of the performance and quality discount of the intensity-modulated conformal field, the influence of the follow-up speed, and the poor treatment efficiency, and achieves fast image follow-up speed, high degree of automation, and universal use. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

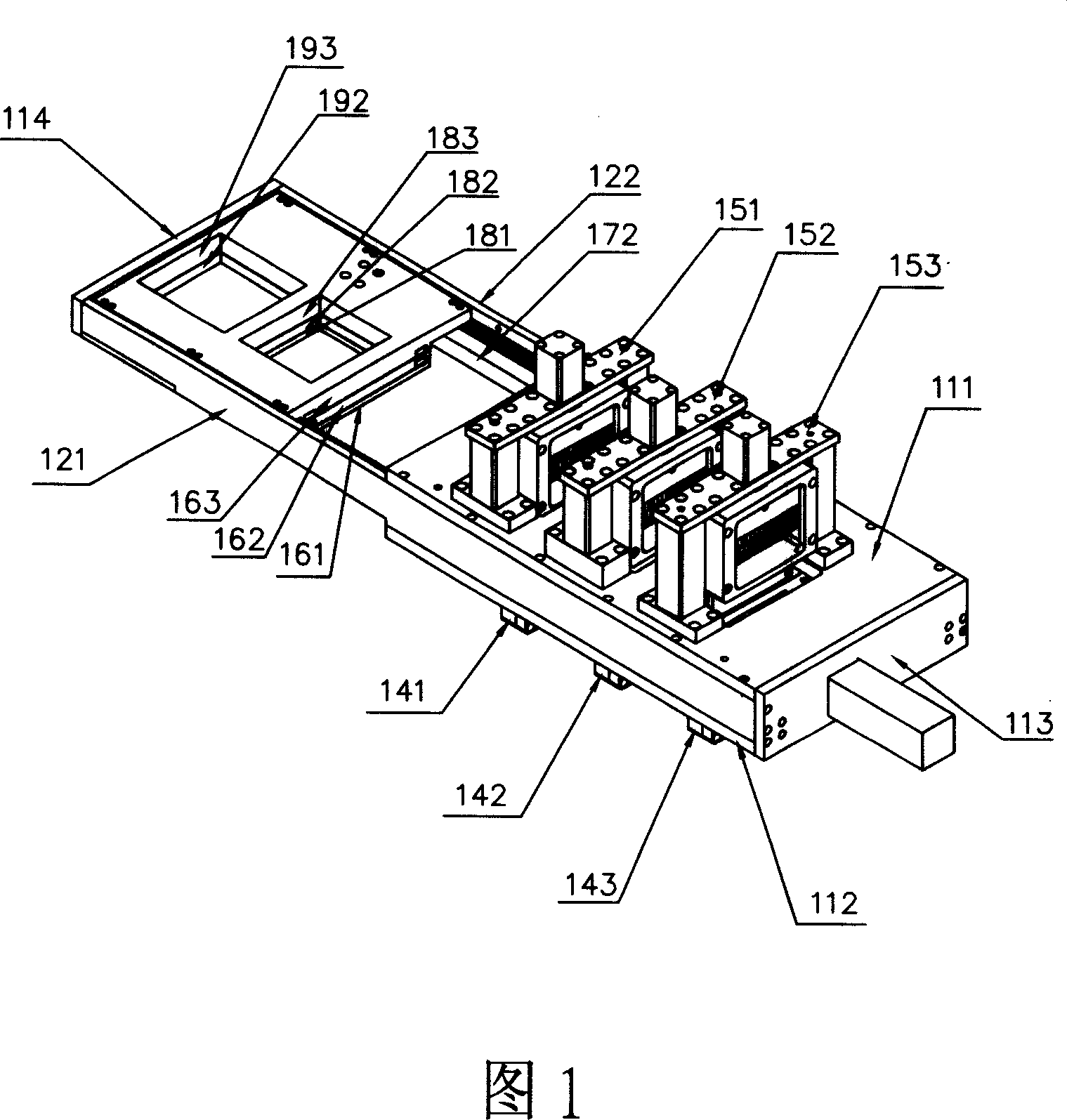

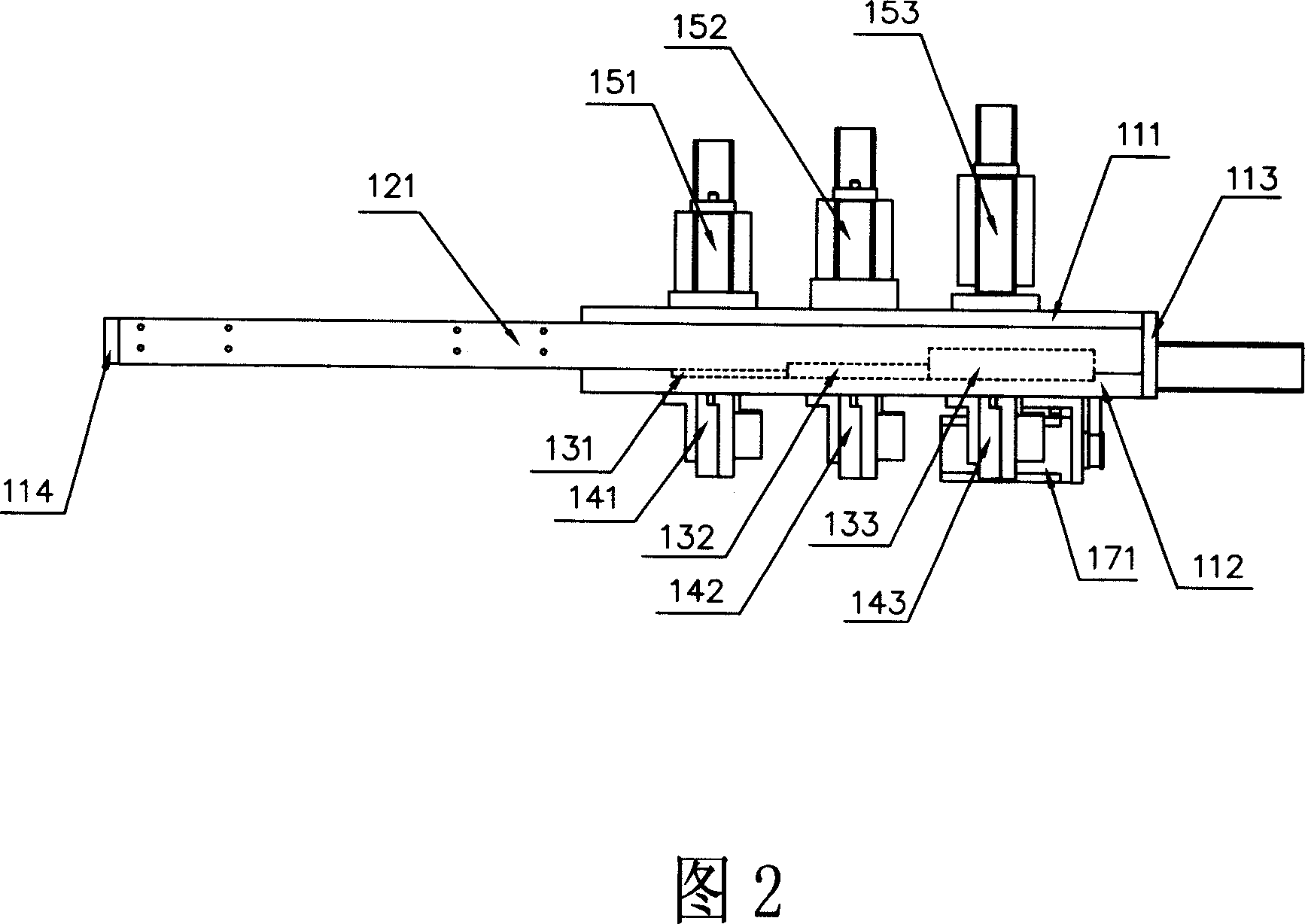

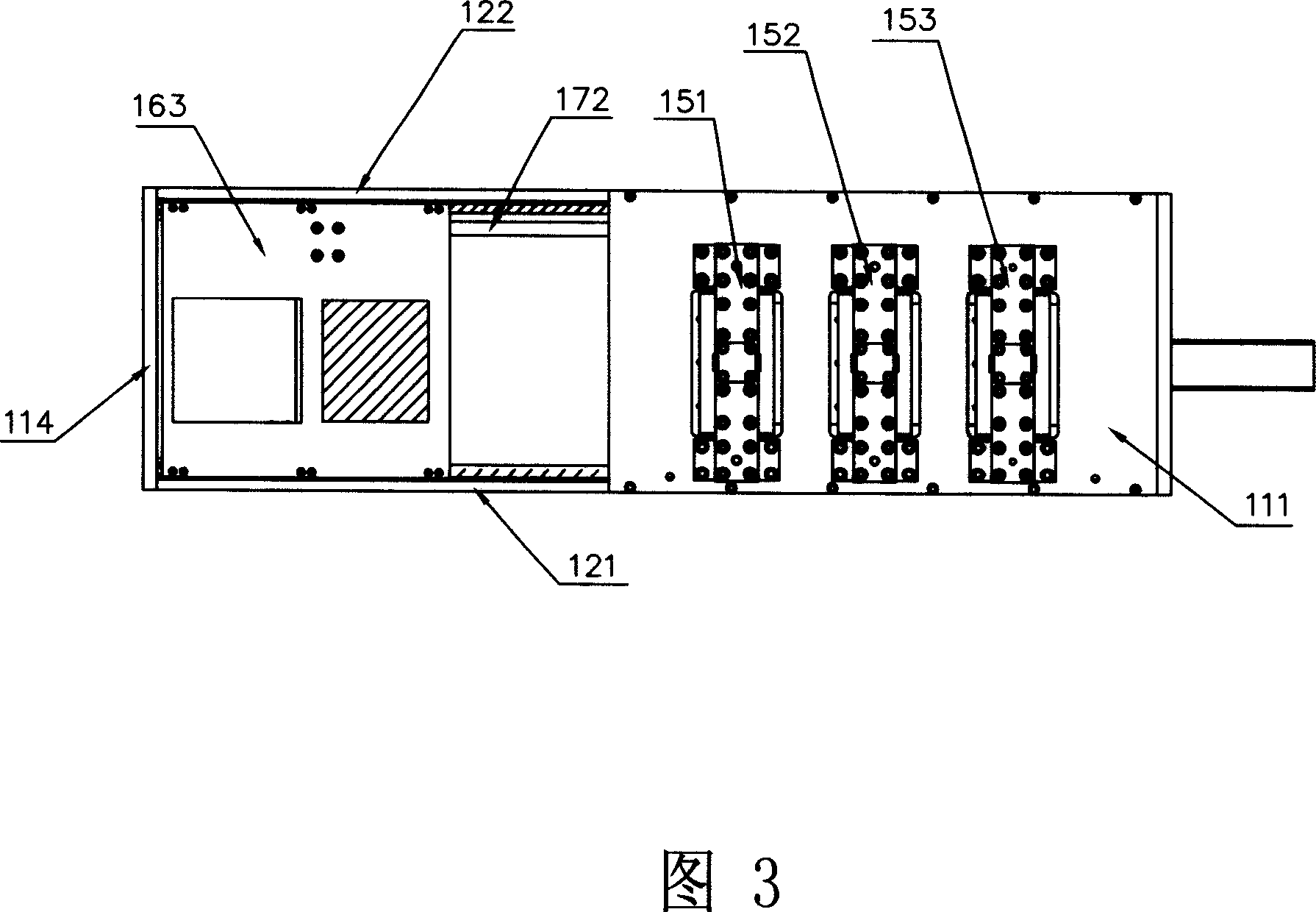

[0019] Please refer to Fig. 1, 2, 3 and 4 in conjunction with, the grating collimator provided by the present invention comprises upper fixed plate 111, lower fixed plate 112, rear fixed plate 113, limit plate 114, guide rail 121,122, magazine device 131 , 132,133, needle pushing device 141,142,143, needle withdrawal device 151,152,153, sub-grating transport device 161,162,163, motor 171, screw mandrel 172.

[0020] The grating collimator provided in this embodiment has three sets of needle withdrawal devices, and the numbers in the drawings are respectively 151, 152 and 153. Correspondingly, there are three needle withdrawal operation holes on the upper fixing plate 111, and the needle withdrawal devices 151, 152 and 153 are horizontally fixed side by side above the upper fixing plate 111, and are respectively located at the three withdrawal operation holes. The grating collimator provided in this embodiment has three sets of magazine devices. The magazine devices 131 , 132 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com