A hydrothermal processing method for fuel battery current field

A hydration treatment and fuel cell technology, which is applied to fuel cells, fuel cell parts, solid electrolyte fuel cells, etc., can solve problems such as uneven gas distribution in the battery pack, water accumulation, MEA flooding, etc., to achieve The effect of reducing MEA flooding phenomenon, reducing water management pressure, and improving water increasing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

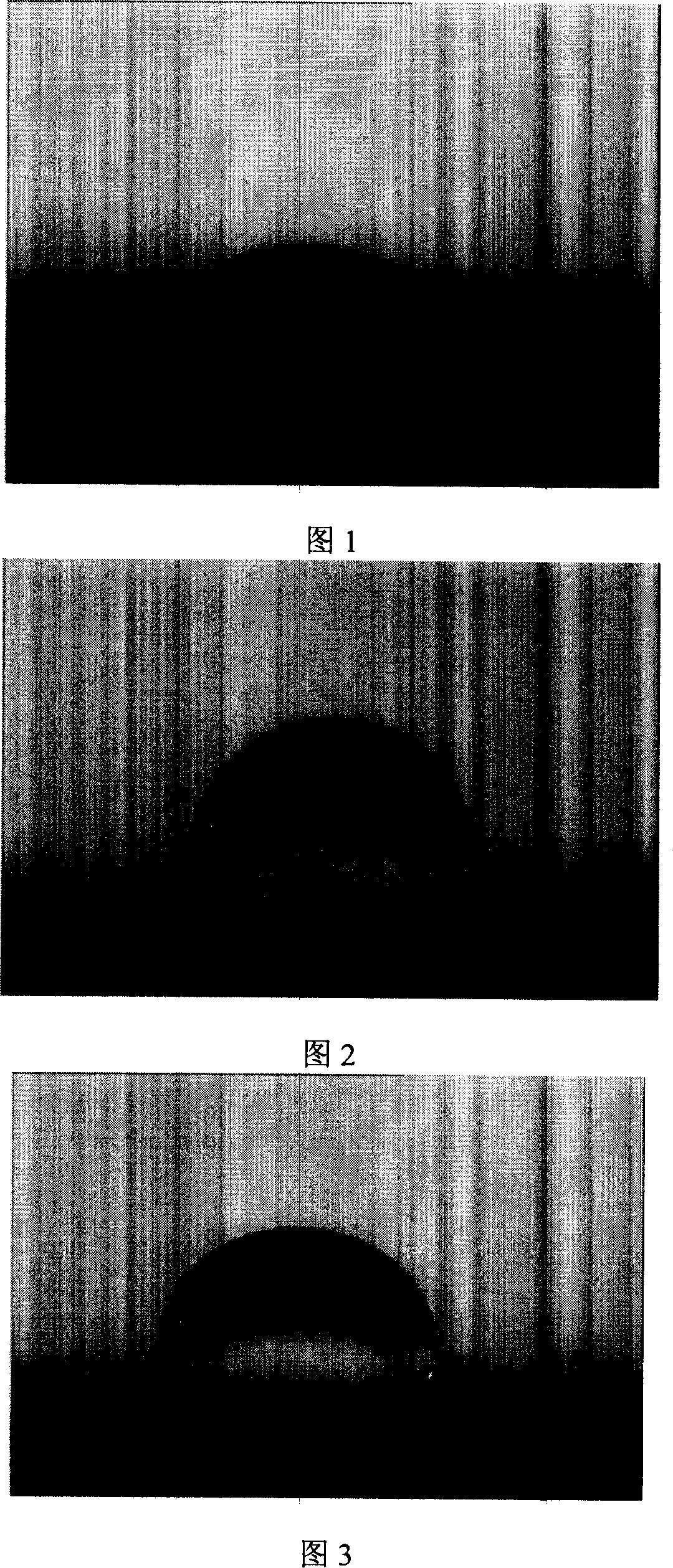

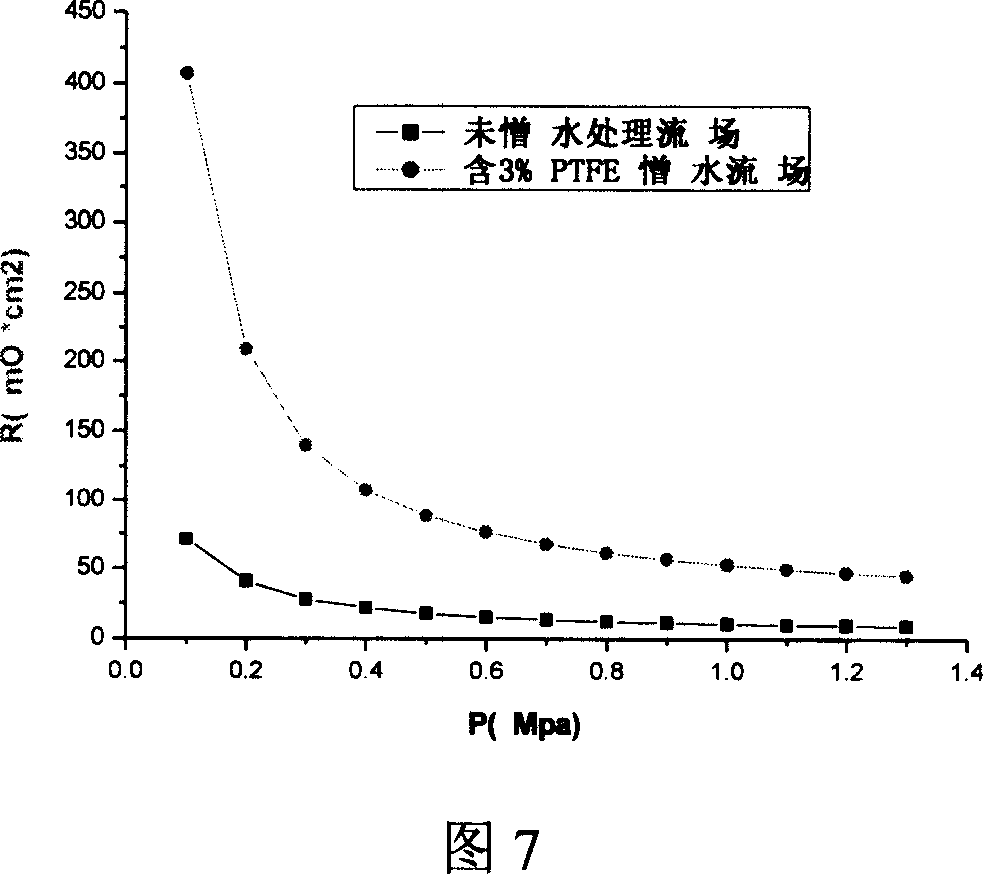

[0022] According to the method of the present invention, 60% PTFE emulsion is used to configure 2% PTFE solution, and the expanded graphite flow field plate is soaked once or several times, so that the content of tetrafluoride in the flow field is controlled at 0.5%. Then put the soaked flow field into a vacuum oven and bake and cure at 350° C. for 2 hours. Finally, the boss part of the surface of the flow field is polished to remove the non-conductive substance on the surface. The surface contact angle (Figure 1 and Figure 2) and contact resistance (Figure 5) of the flow field plate after hydrophobic treatment were tested. The results show that the resistance of the flow field does not increase much, but the water increase performance of the flow field is significantly improved.

Embodiment 2

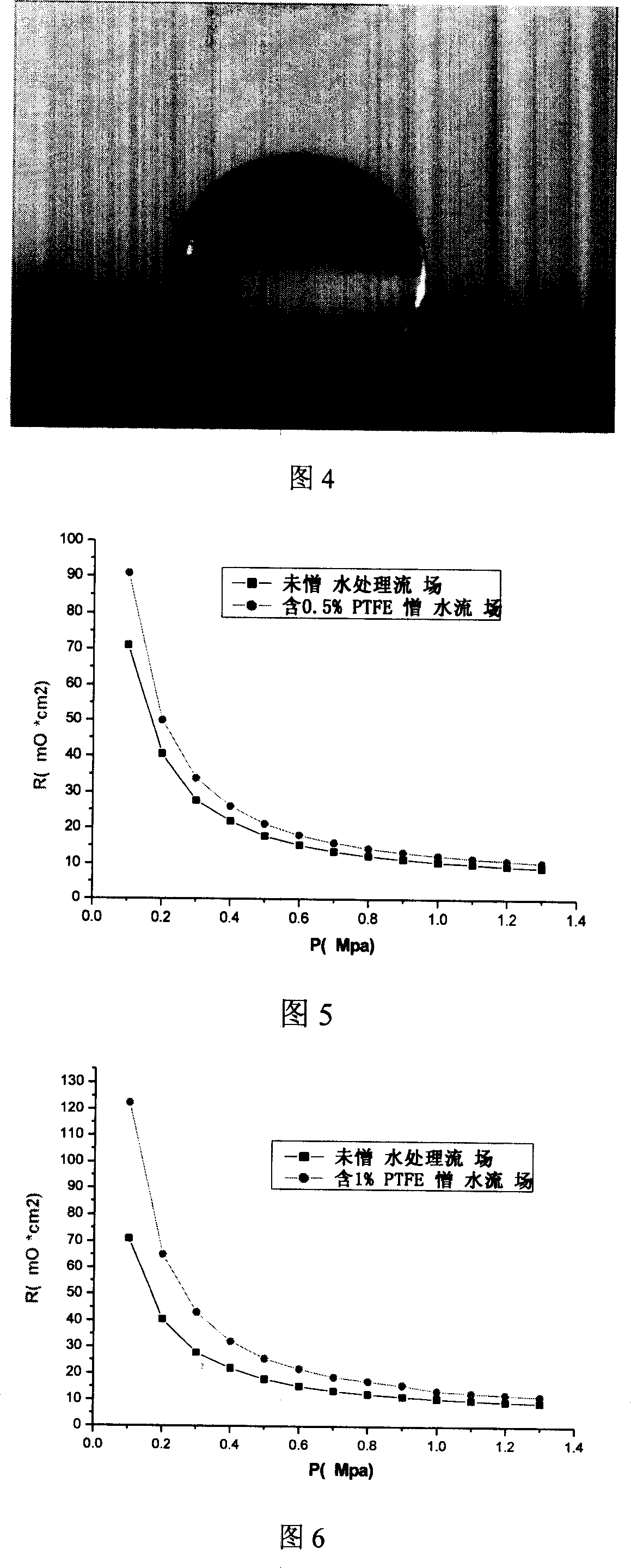

[0024] According to the method of the present invention, 60% PTFE emulsion is used to prepare 5% PTFE solution, and the expanded graphite flow field plate is soaked once or more times, so that the tetrafluoroethylene content in the flow field is controlled at 1%. Then put the soaked flow field into a vacuum oven and bake and cure at 400° C. for 1 hour. Finally, the boss part of the surface of the flow field is polished to remove the non-conductive substance on the surface. The surface contact angle (Fig. 3) and contact resistance (Fig. 6) of the flow field plate after hydrophobic treatment were tested. The results show that the resistance of the flow field does not increase much, but the water increase performance of the flow field is significantly improved.

Embodiment 3

[0026] According to the method of the present invention, 60% PTFE emulsion is used to configure 5% PTFE solution, and the expanded graphite flow field plate is soaked once or more times, so that the tetrafluoroethylene content in the flow field is controlled at 3%. Then put the soaked flow field into a vacuum oven and bake and cure at 400° C. for 1 hour. Finally, the boss part of the surface of the flow field is polished to remove the non-conductive substance on the surface. The surface contact angle (Figure 4) and surface contact resistance (Figure 7) of the flow field plate after hydrophobic treatment were tested. The results show that 3% PTFE in the flow field will lead to an increase in the resistance of the flow field plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com