Method and system for measuring water hardness

A technology for water hardness and detection of water, applied in the direction of testing water hardness, testing water, immunoassay, etc., can solve the problems of slow and inaccurate methods, and achieve the effect of reducing the excessive use of chelating agents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

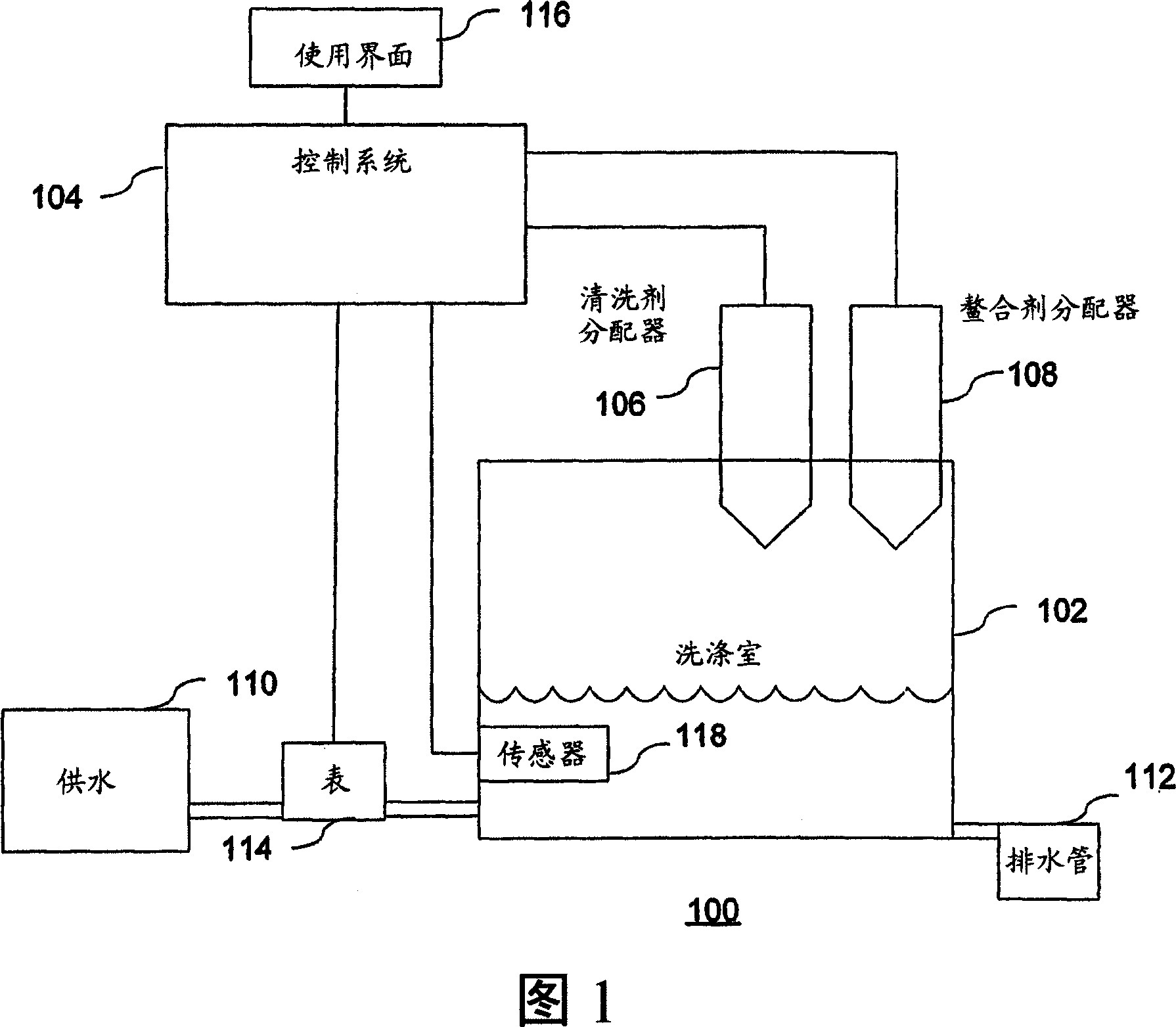

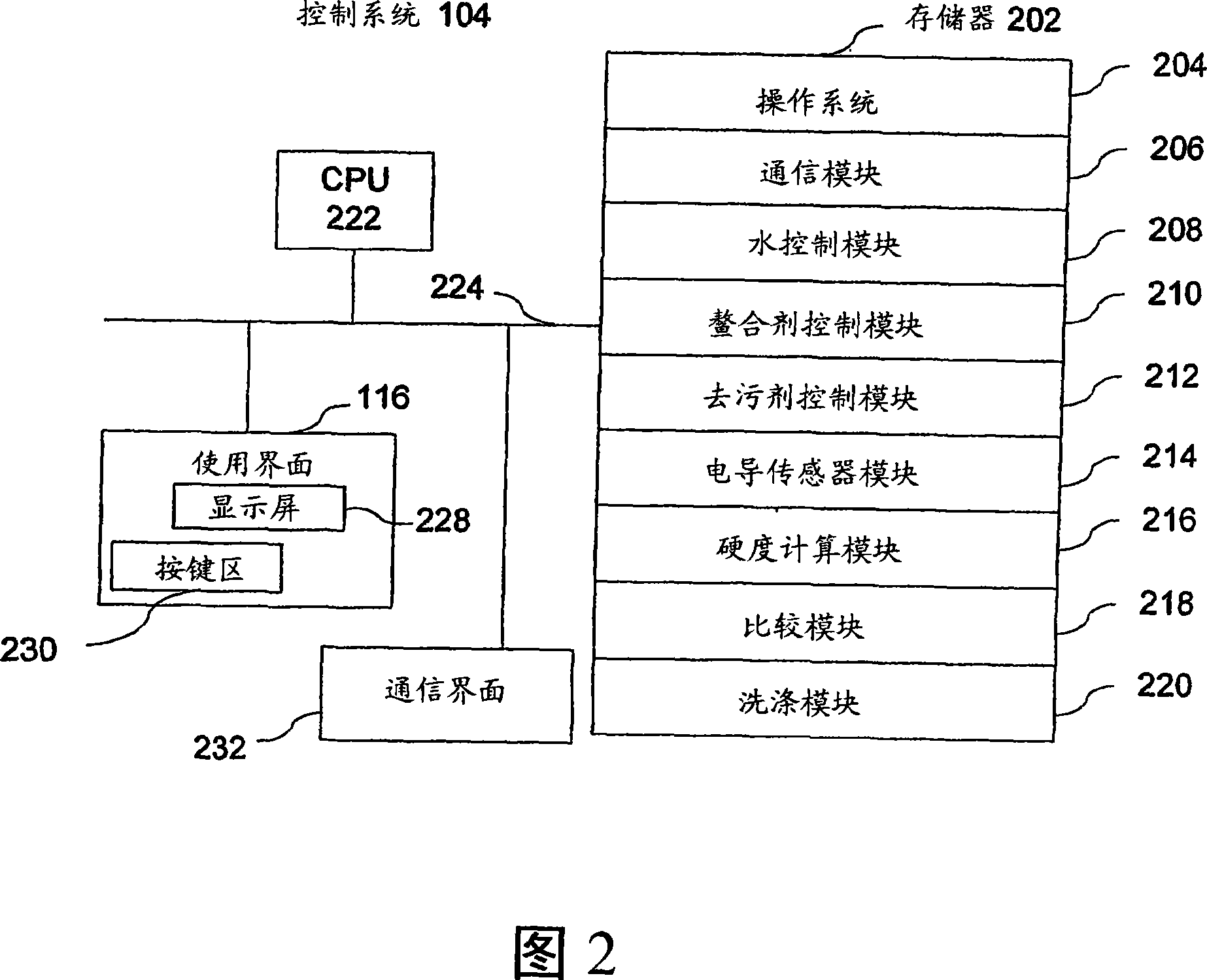

[0019] Water hardness is determined in a novel manner using a conductivity sensor, one or more chelating agents, and a computer-controlled chemical dispersion system.

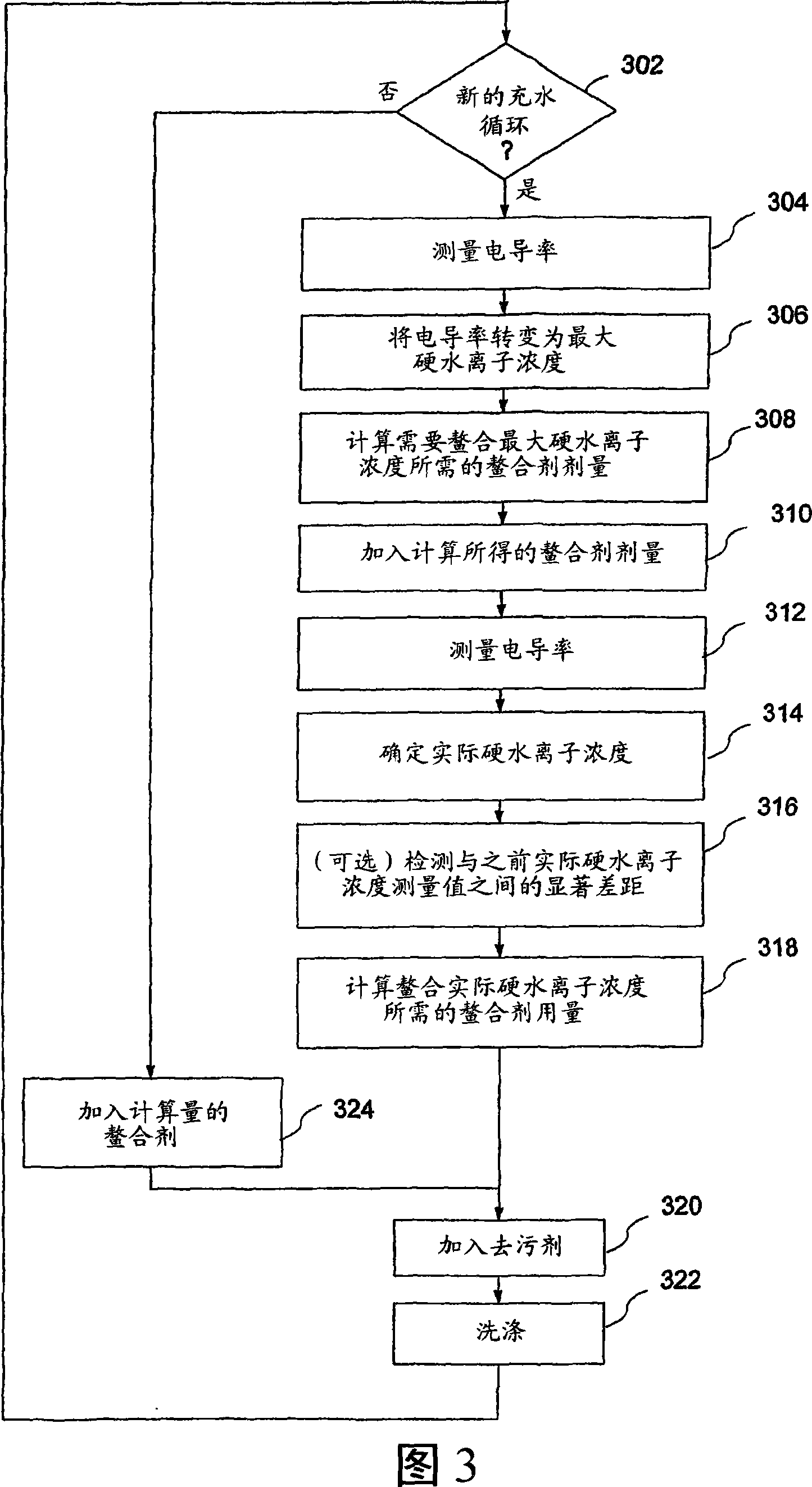

[0020] In certain embodiments, when a new water fill cycle is detected, an initial conductivity measurement of the water in the wash compartment is determined. Determine the maximum concentration of hard water ions that is equivalent to the measured conductivity, that is, even though other ions may actually affect the measured conductivity, assuming that all conductivity is caused by the caused by calcium and / or magnesium ions. Then, add enough chelating agent to the wash chamber to sequester these maximum concentrations of hard water ions and measure the conductivity again. Using these two conductivity measurements, the actual concentration of hard water ions is determined. The chelating factor based on the actual concentration of hard water ions is then used to determine the amount of chelating agent to be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com