Solar energy flat glass house novel structure

A solar panel and glass house technology, applied to lighting and heating equipment, drying, furnace types, etc., can solve the problems of many consumables, low luminous flux, and high cost, and achieve high luminous flux, safe consumables, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

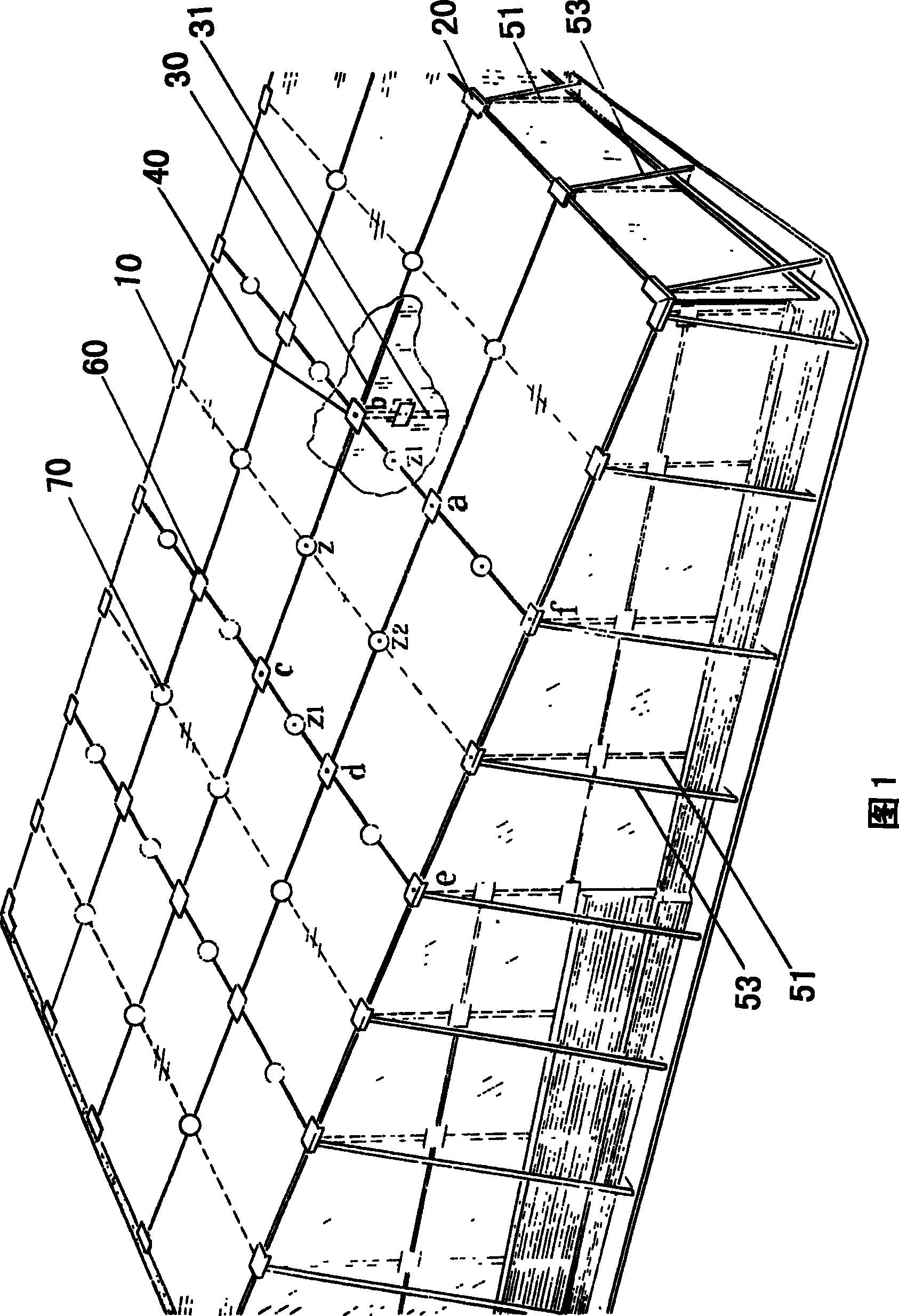

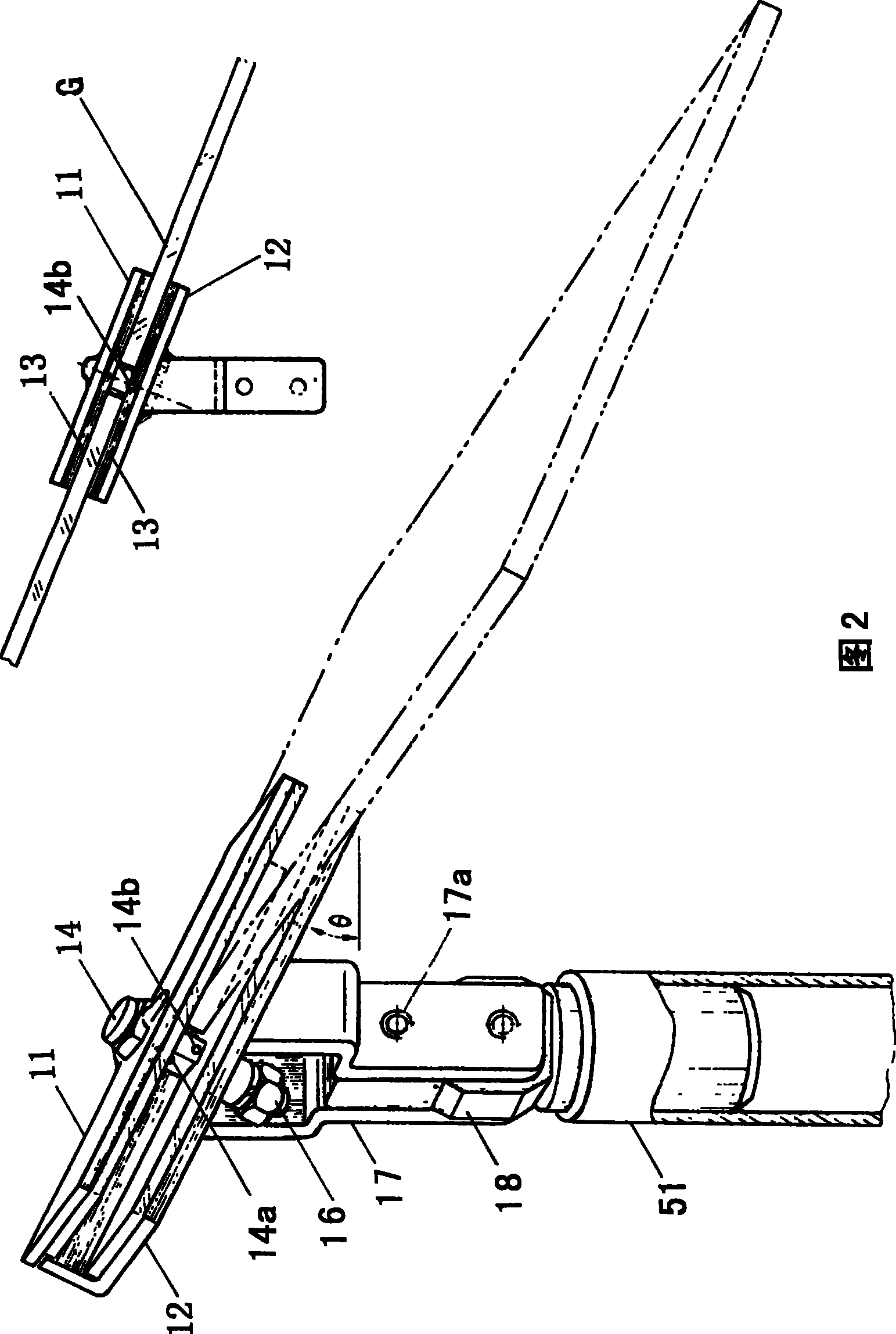

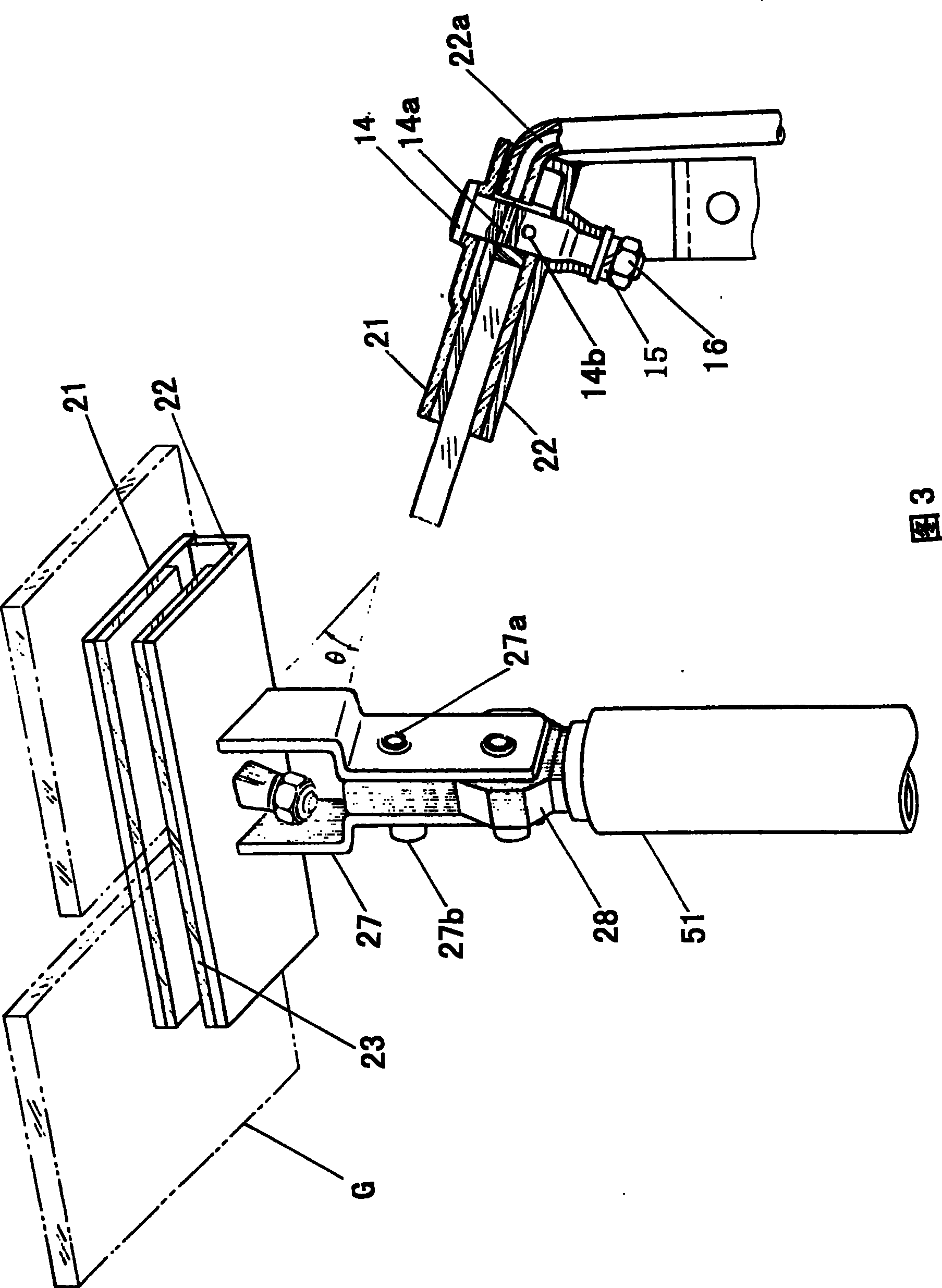

[0016] The features of the present invention are: 1. figure 1 The southeast and west three sides are all glass walls, and the north is a reinforced concrete partition wall (the middle partition is insulation material). The periphery of these four walls is evenly distributed with a tripod 50 welded by steel pipes, and its riser 51 (right-angled side) In the wall, the inclined pipe 53 (hypotenuse) is obliquely braced outside the wall, and the short right-angled side is horizontally embedded in the ground silicon base; Aluminum-zinc anti-corrosion) tensioned, criss-crossed steel wires form the entire roof slope. Four kinds of room surface clips are installed on the top of each tripod 50 with screws; On the steel wire, there are bolts with horizontal holes in the string, and then clamp the upper and lower clips with bolts (rubber gaskets are lined between the clip and the glass), and at the same time clamp each adjacent piece of glass and fix it with the tensioned steel wire , J...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap