High accuracy vision detection system

A visual detection, high-precision technology, applied in the field of high-precision non-contact testing devices, can solve the problem that the detection system is difficult to meet the detection accuracy, and achieve the effect of strong anti-interference ability and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

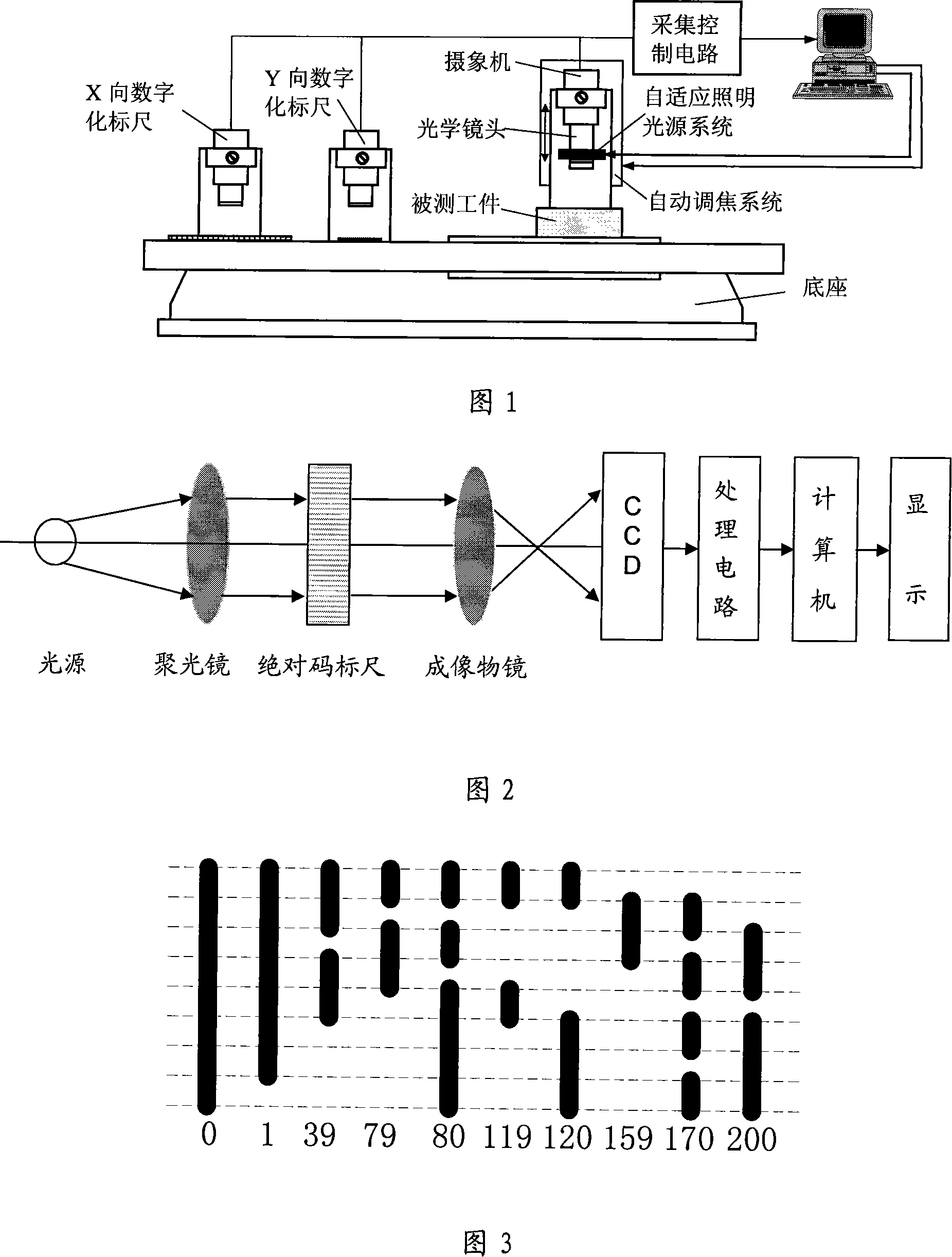

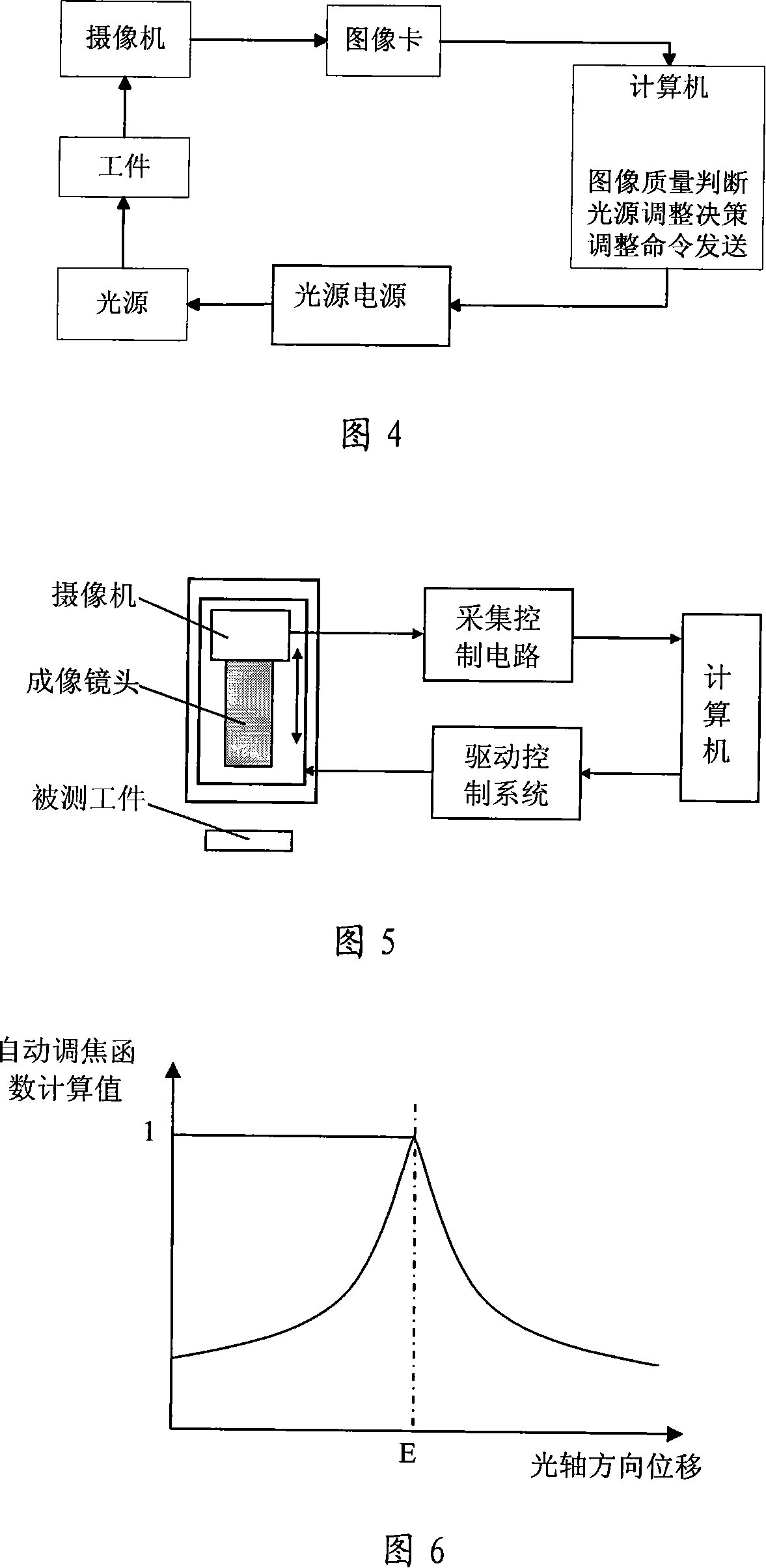

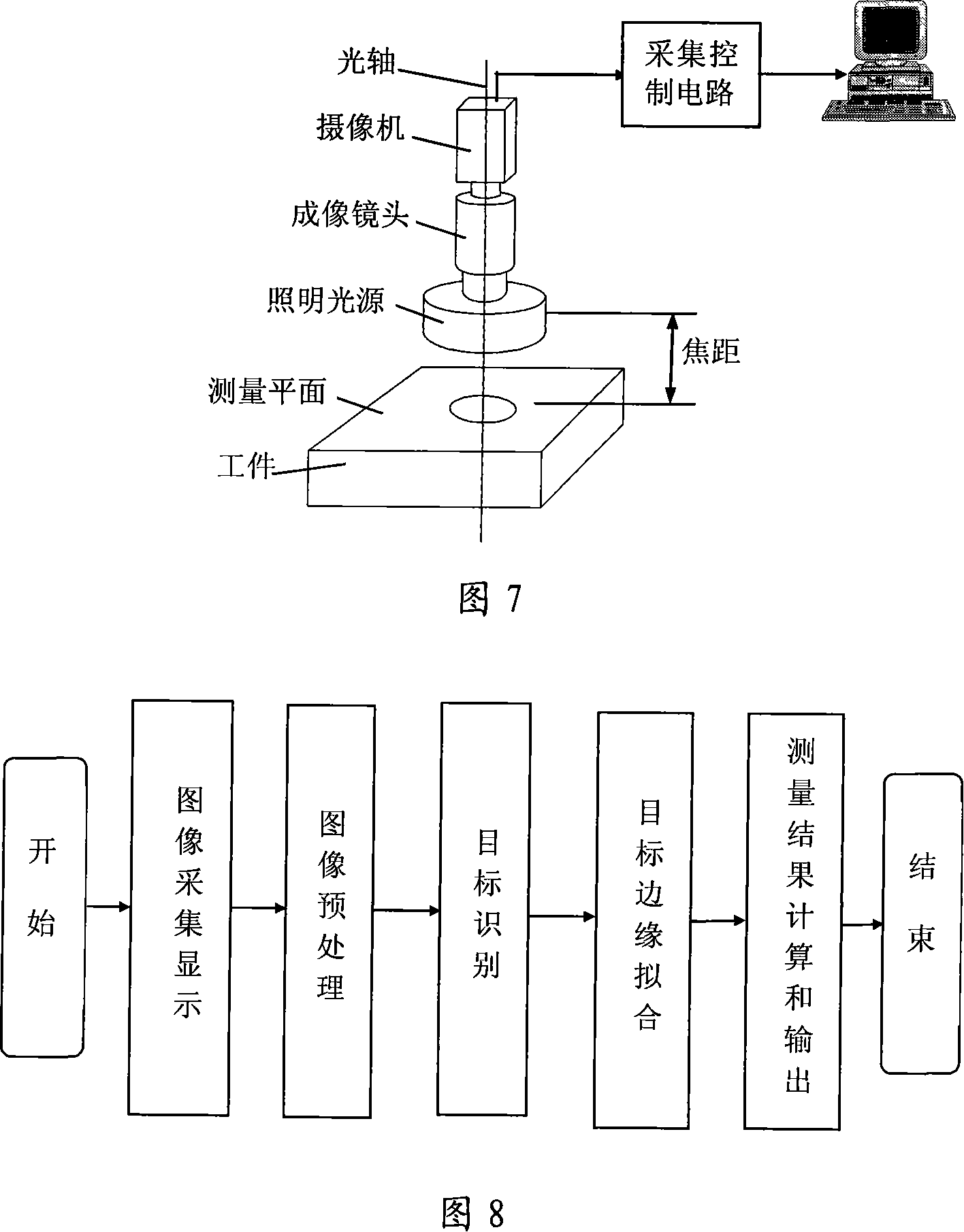

[0025] As shown in Figure 1, the present invention is composed of a digital scale system, an adaptive light intensity adjustment lighting system, an automatic focusing system, an optical imaging system, visual inspection software, a base, a computer or a micro-processing system. The X-direction and Y-direction digital scale systems pick up the position information of the photosensitive surface of the camera in the machine coordinates in the vertical and horizontal directions respectively. The digital scale systems in the two directions each have a camera, and the signals collected by the camera are sent to the camera through the image acquisition control circuit. The computer determines the coordinate values of the two directions through image processing technology; the self-adaptive adjustment light intensity lighting system uses the image quality evaluation function to judge the image quality collected by the optical imaging system, and the computer adjusts the output of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com