Propylene oxidation unit DCS control system in crylic acid device

A technology of propylene oxidation and control system, which is applied in the direction of electrical program control, comprehensive factory control, organic chemistry, etc., can solve the problems of affecting the service life of the catalyst, increasing the separation cost of the acrylic acid refining system, increasing the steam consumption, etc., achieving considerable economic benefits, The effect of reducing human interference and safe and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0036] Taking the propylene oxidation unit of an acrylic acid plant with an annual output of 80,000 tons as an example, DCS control is used to illustrate the situation of the present invention.

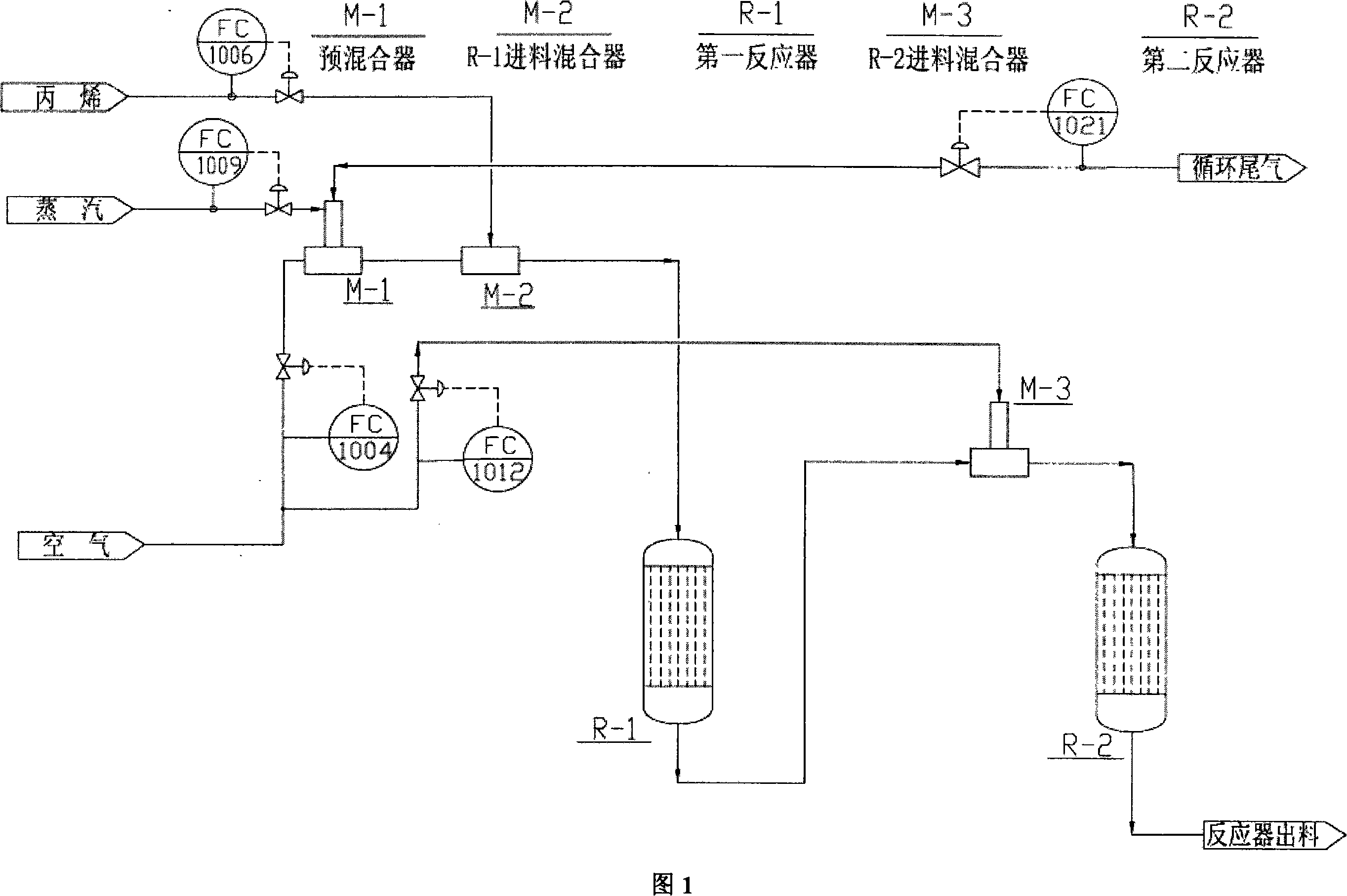

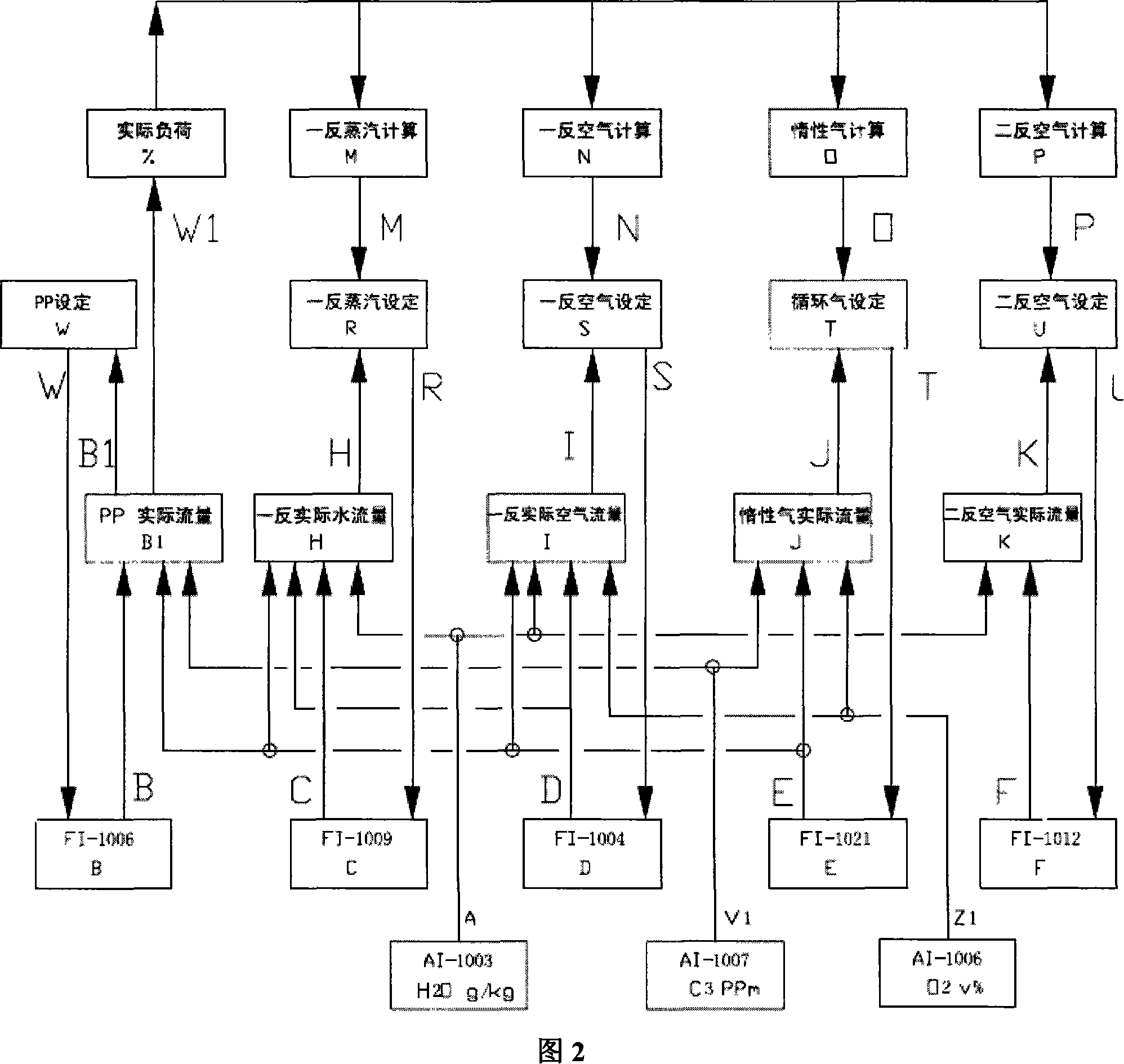

[0037] The flow of steam is measured through the orifice plate and differential pressure transmitter; the flow of air is measured through Annubar and differential pressure transmitter; the flow rate of circulating exhaust gas is measured through the orifice plate and differential pressure transmitter, and the three enter the pre-mixer M- 1. Fresh propylene enters the feed mixer M-2 after flow measurement, and then enters the mixer M-2 with fresh propylene after mixing, and then enters the first reactor R-1; the reaction gas after the reaction in the first reactor enters The feed mixer M-3 is mixed with the supplementary air of the second reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com