Heat-conducting gas supply mechanism, supply method and substrate processing device and method

A substrate processing device and gas supply technology, applied in gas/liquid distribution and storage, electrical components, plasma, etc., can solve problems such as pressure deviation, glass substrate processing quality degradation, PCV pressure responsiveness damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

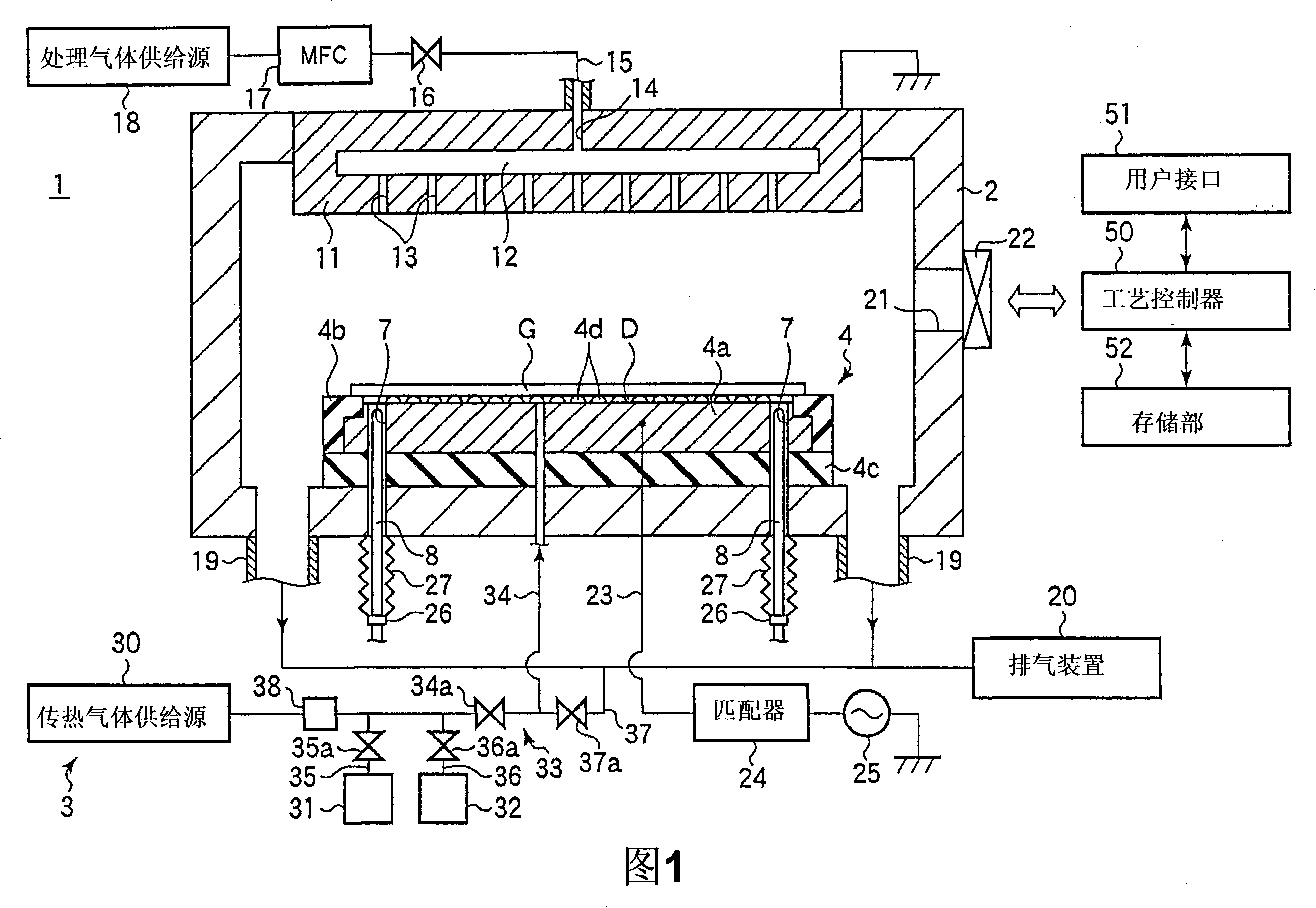

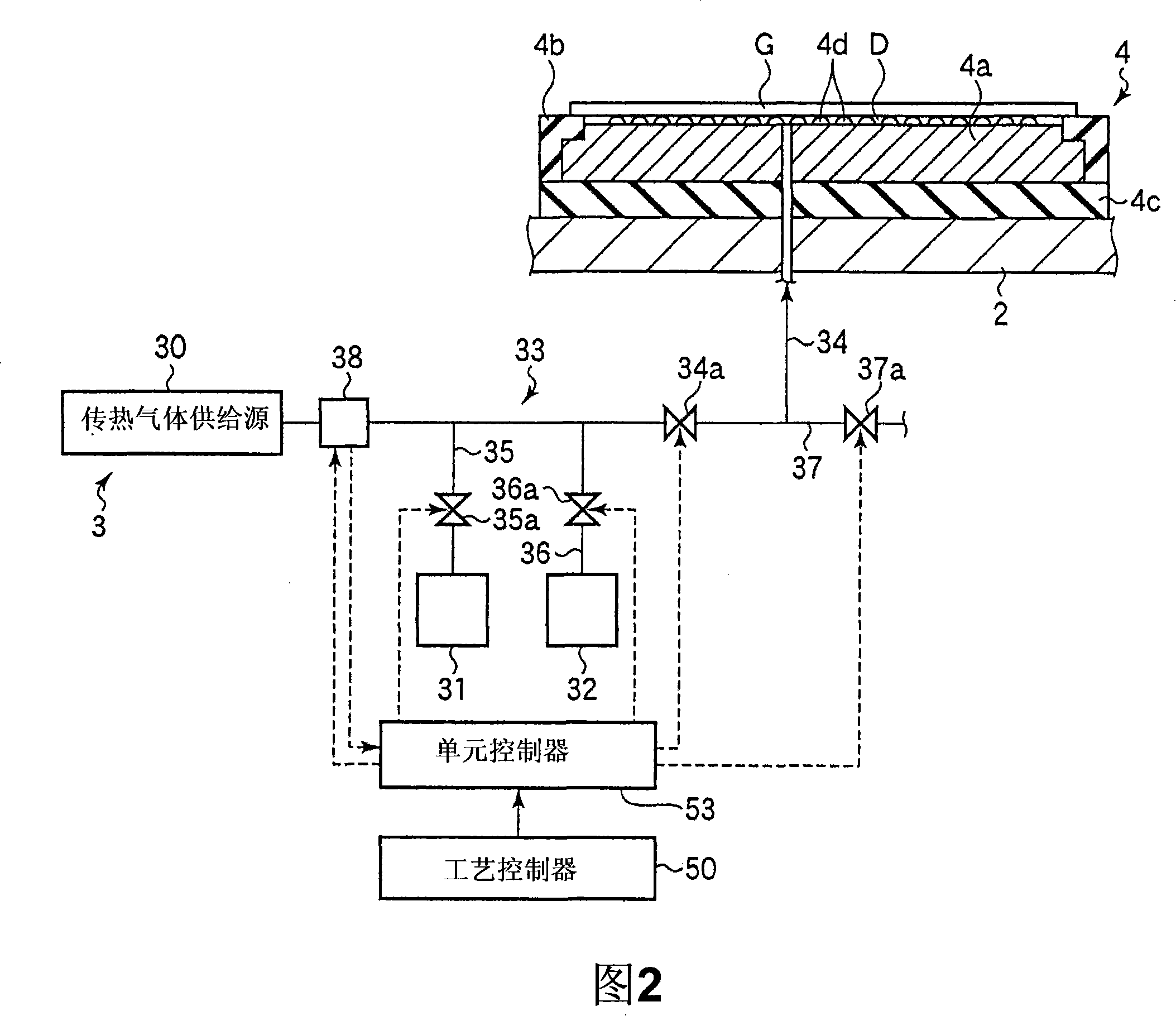

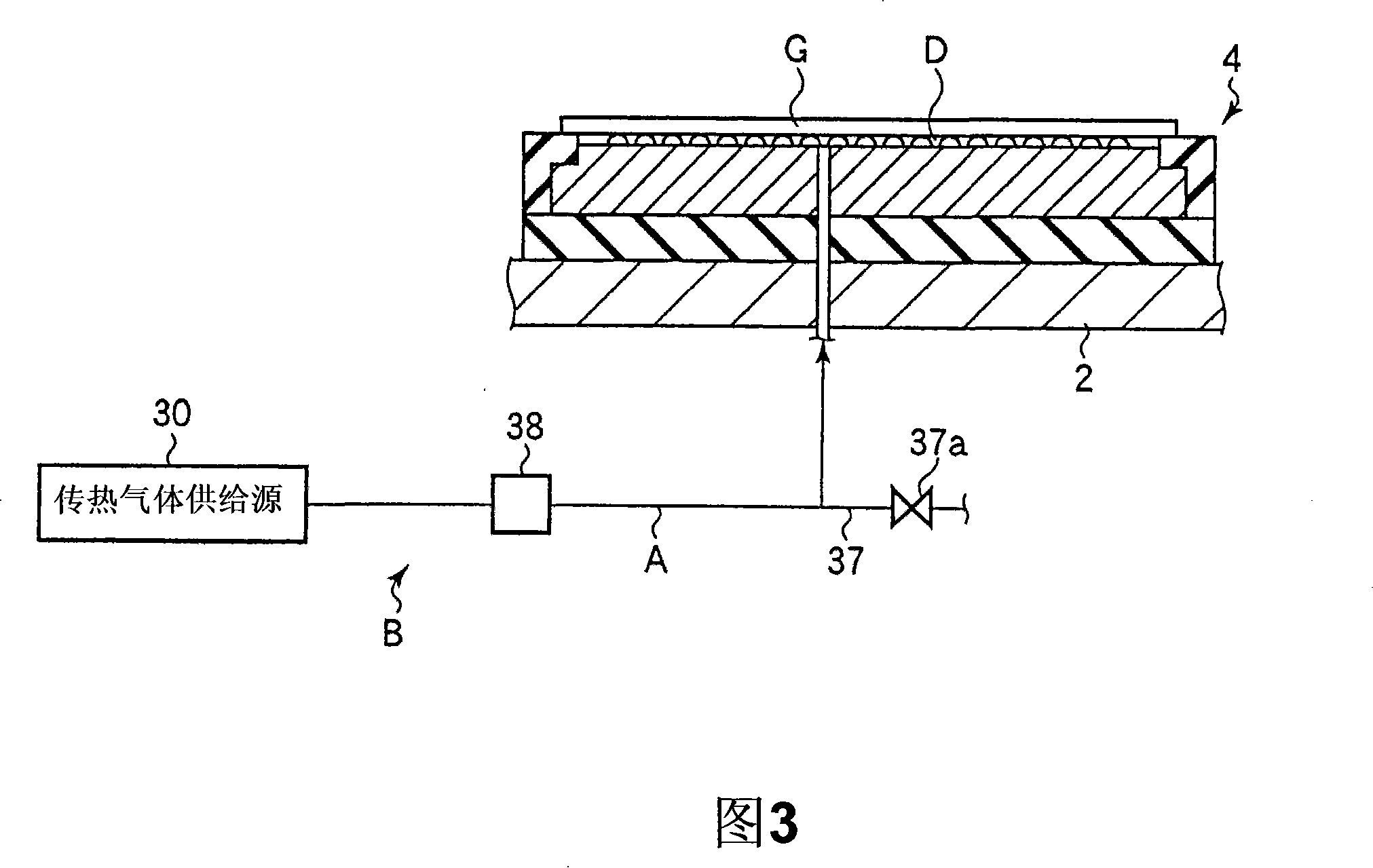

[0052] 1 is a schematic cross-sectional view of a plasma etching apparatus as one embodiment of a substrate processing apparatus according to the present invention, and FIG. 2 is a schematic diagram of a heat transfer gas supply mechanism constituting the plasma etching apparatus.

[0053] This plasma etching apparatus 1 is configured as a capacitively coupled parallel plate plasma etching apparatus for etching a glass substrate (hereinafter referred to as “substrate”) G for FPD. Examples of the FPD include a liquid crystal display (LCD), an electroluminescence (EL) display, a plasma display panel (PDP), and the like. The plasma etching apparatus 1 has a chamber 2 as a processing container for accommodating a substrate G. As shown in FIG. The chamber 2 is made of, for example, aluminum whose surface is subjected to alumite treatment (anodization treatment), and is form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com