Difference elliptic gear transplanting mechanism and uses thereof

The technology of oval gear and circular gear is applied in the field of high-efficiency sparse planting mechanism, which can solve the problems of reduced use range, unsuitable for rice planting with large plant spacing and sparse planting requirements, etc., and achieves the effects of reasonable structure, high transplanting efficiency and reliable work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

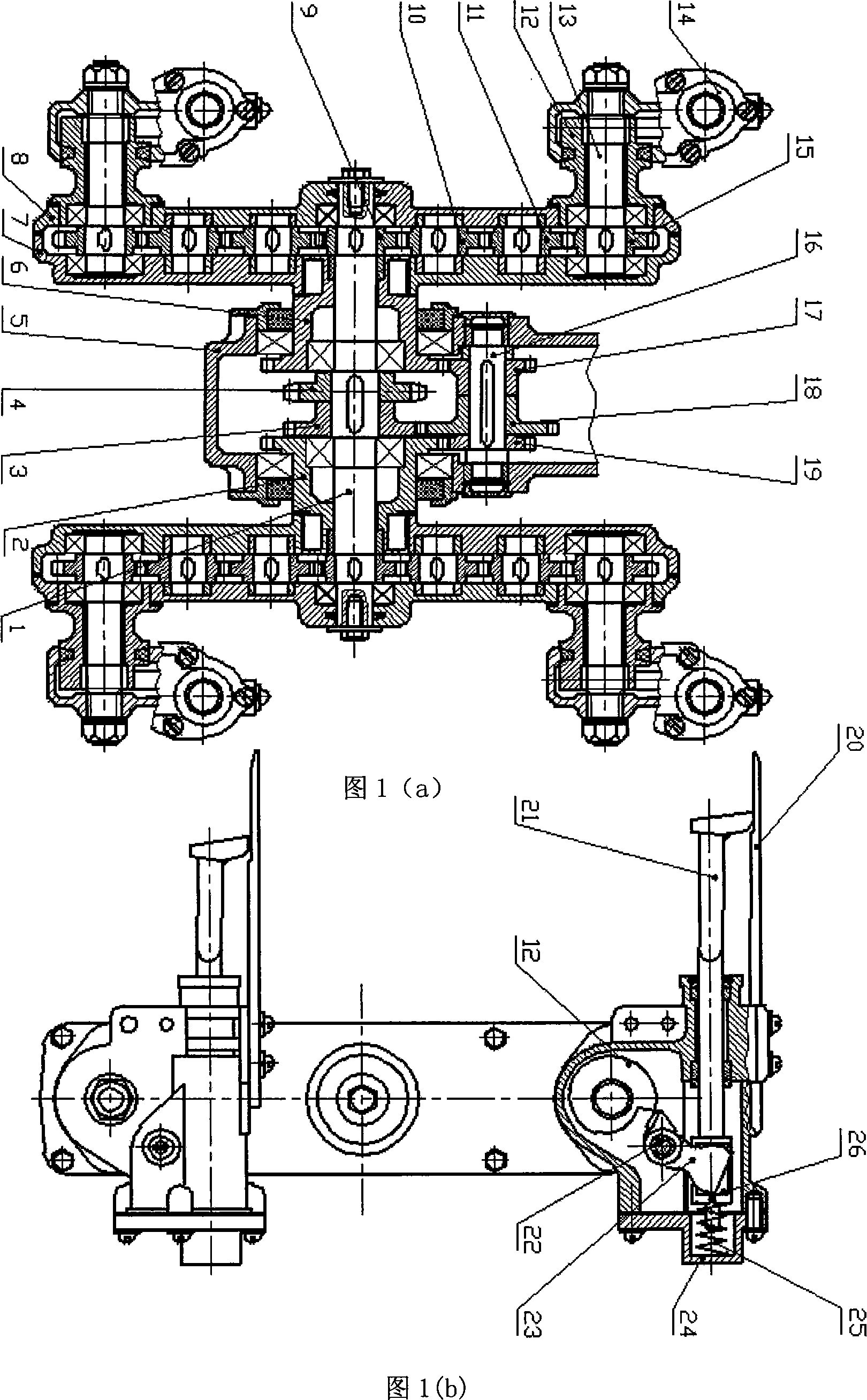

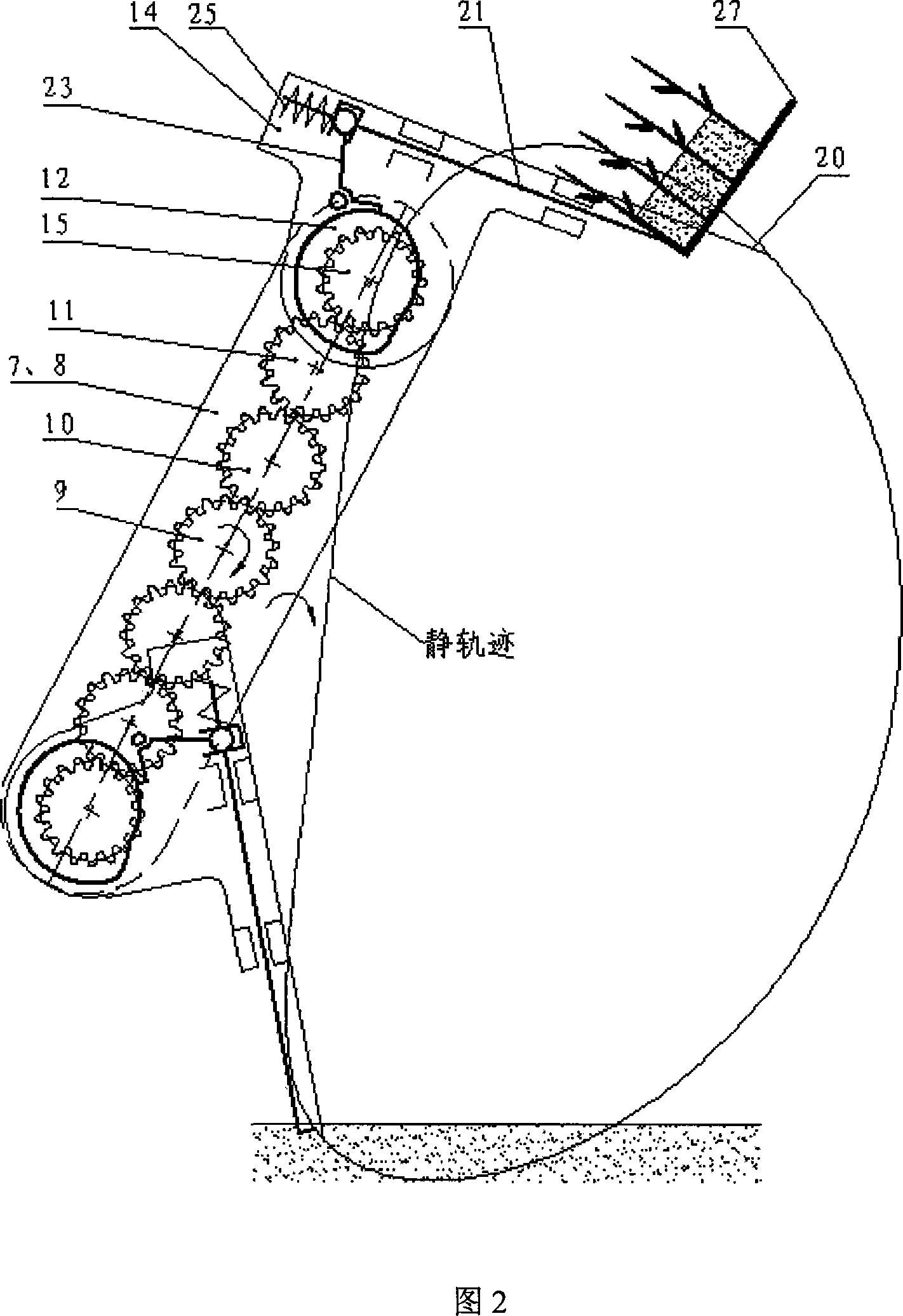

[0015] In Fig. 1, in the sprocket box (5), the power is transmitted to the driven sprocket (4) through the chain, and the driven sprocket (4) is consolidated with the driven sprocket shaft (1). Taking the left side structure of the whole device as an example, the upper and lower parts are symmetrical about the center line of the driven sprocket shaft (1). The other end of the driven sprocket shaft (1) is consolidated with the central oval gear (9), and the other end of the left sliding sleeve gear (6) is consolidated with the right casing (7) of the gear box. The power is transmitted in two routes: one transmission route is that the power is transmitted to the intermediate transition gear (18) meshed with the transition shaft (16) through the flange gear (3) installed on the same shaft as the driven sprocket (4) (transmission ratio is -1), drive the left and right transition gears (17,19) installed on both sides of intermediate transition gear (18) on the transition shaft (16)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com