A fluid pressure expanding type cutter chuck

A tool chuck and expansion technology, which is applied in the mechanical field, can solve the problems that cannot meet the requirements of high precision, and achieve the effect of providing surface quality, easy and convenient loading and unloading of tools, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

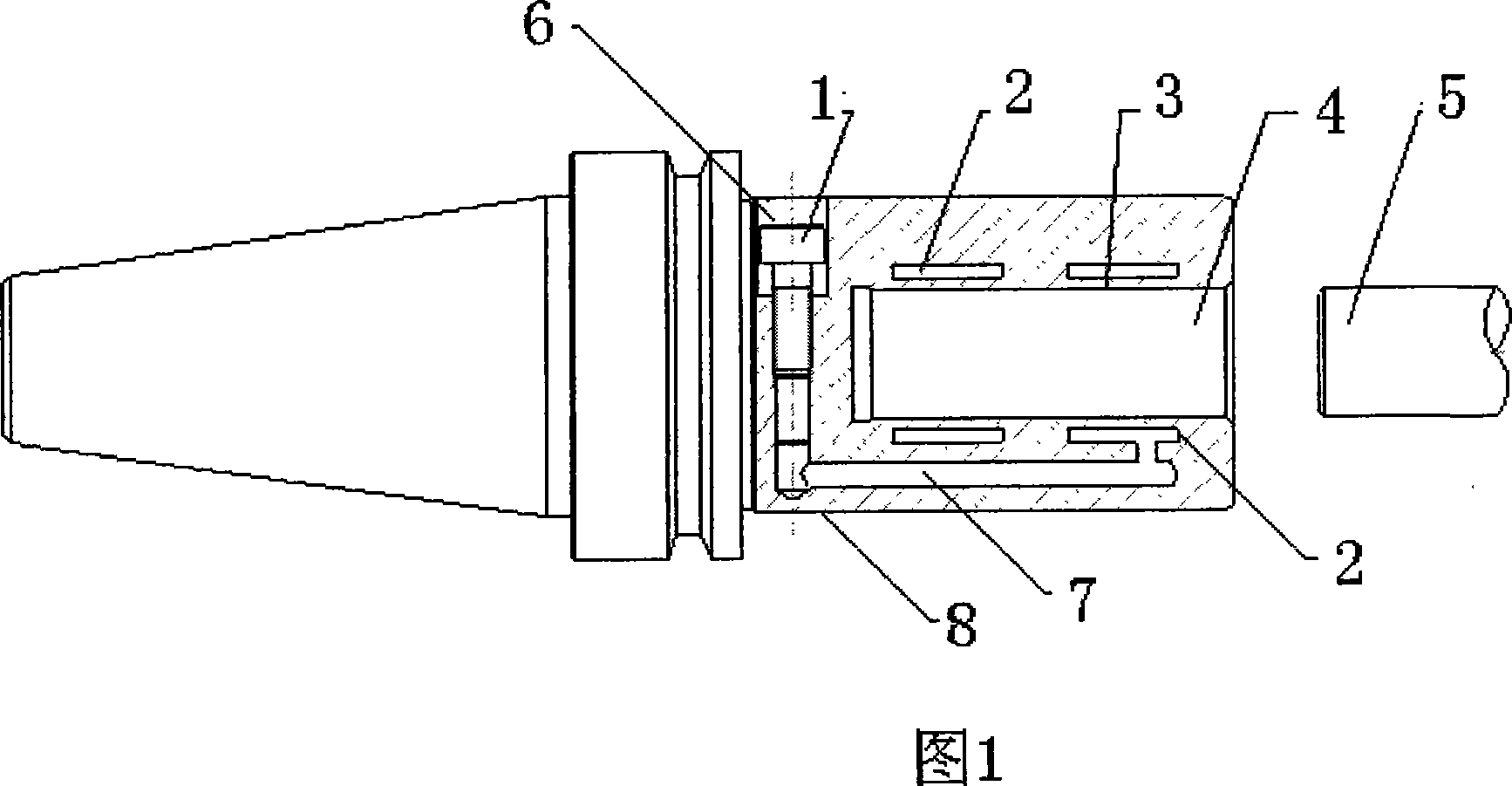

[0012] Embodiment 1: As shown in Figure 1,

[0013] The structure of the hydraulic expansion tool chuck is shown in the figure. There is an annular closed oil chamber 2 between the chuck body 8 and the expansion wall 3 of the clamping hole 4. The oil chamber 2 is filled with special hydraulic oil, which can The oil pressure is evenly transmitted to each part of the sealed oil chamber 2. There is a hole 6 on the chuck body 8, the hole 6 communicates with the oil chamber 2 through the oil passage 7, one end of the hole 6 is connected with a pressure bolt 1 to match, and the expansion wall of the clamping hole 4 is set through accurate calculation, It has good elasticity and can produce the required amount of expansion when the oil pressure reaches the set value. The tool 5 is put into the clamping hole 4, when the pressure bolt 1 is tightened with an inner hexagonal wrench to increase the oil pressure in the oil chamber, every part of the closed oil chamber 2 will receive the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com