Yielding-water as well as ink automatic control system for offset machine

An automatic control system and technology of offset printing presses, applied in printing presses, rotary printing presses, offset rotary printing presses, etc., can solve the problems of waste of energy, insufficient thrust, easy jamming, etc., to improve printing quality, achieve ink balance, The effect of ensuring print quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

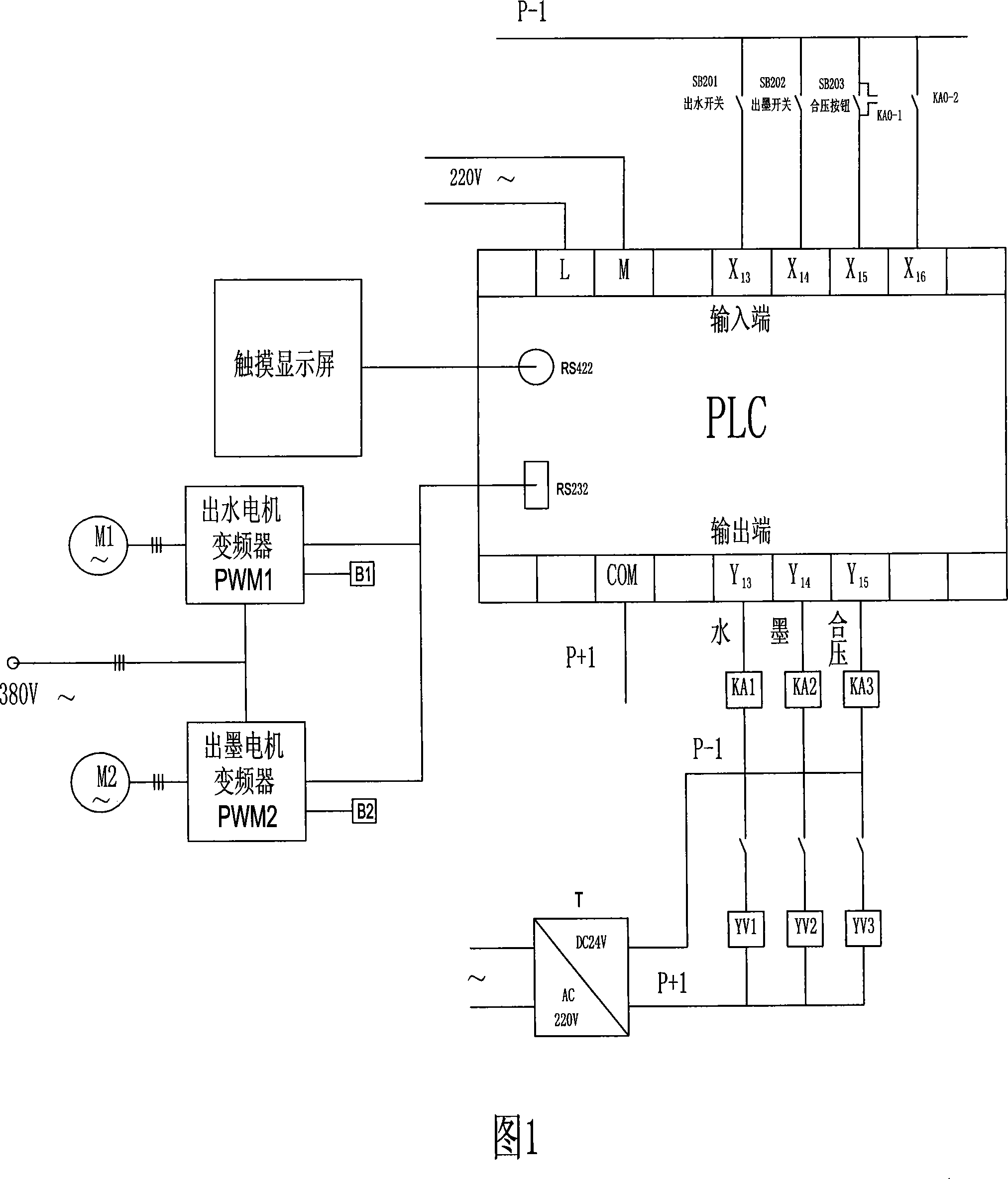

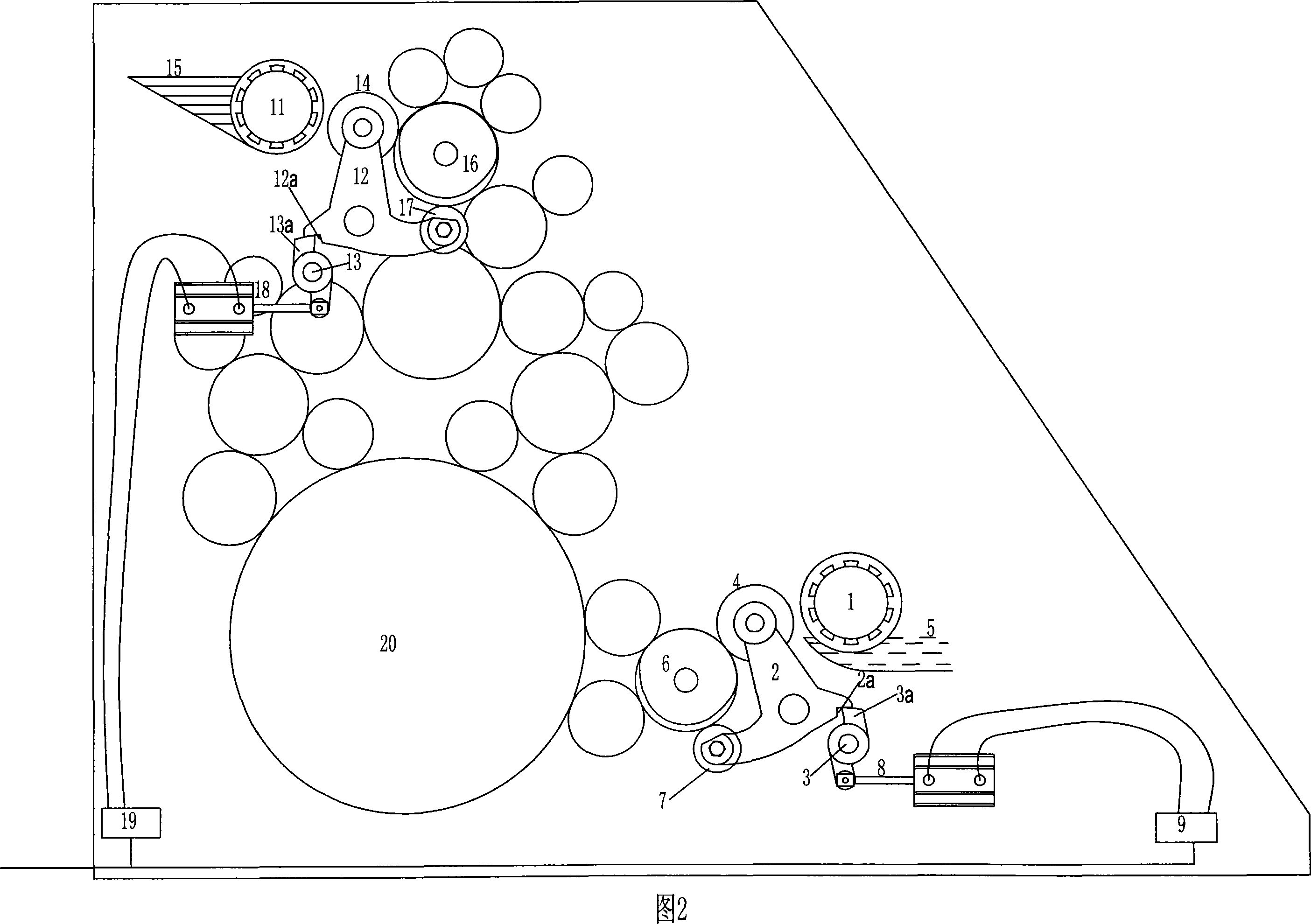

[0009] The technical scheme of the present invention will be further described below in conjunction with the drawings.

[0010] Refer to Fig. 1, the programmable controller includes CPU chip, memory EPROM and RAM, the programmable controller model uses Mitsubishi FX1N-40. The programmable controller PLC is generally set in the control surface of the offset printing machine, and the set control program and control parameters are input through the touch screen on the control surface. The input terminal X13 of the programmable controller PLC is connected to the water sensor switch SB201, and input The terminal X14 is connected to the ink discharge sensor switch SB202, and the input terminal X15 is connected to the combined pressure sensor SB203. It is connected to the PLC output terminal of the programmable controller and is connected to the water discharge motor inverter PWM1 and the ink discharge motor inverter PWM2 through the interface RS232. The input terminals of the inverter P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com