Batching method for treating middle-low grade alumyte by bayer process

A low-grade bauxite and Bayer process technology, applied in the direction of alumina/hydroxide, etc., to achieve sustainable development, prolong mine service life, and avoid the loss of mineral resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

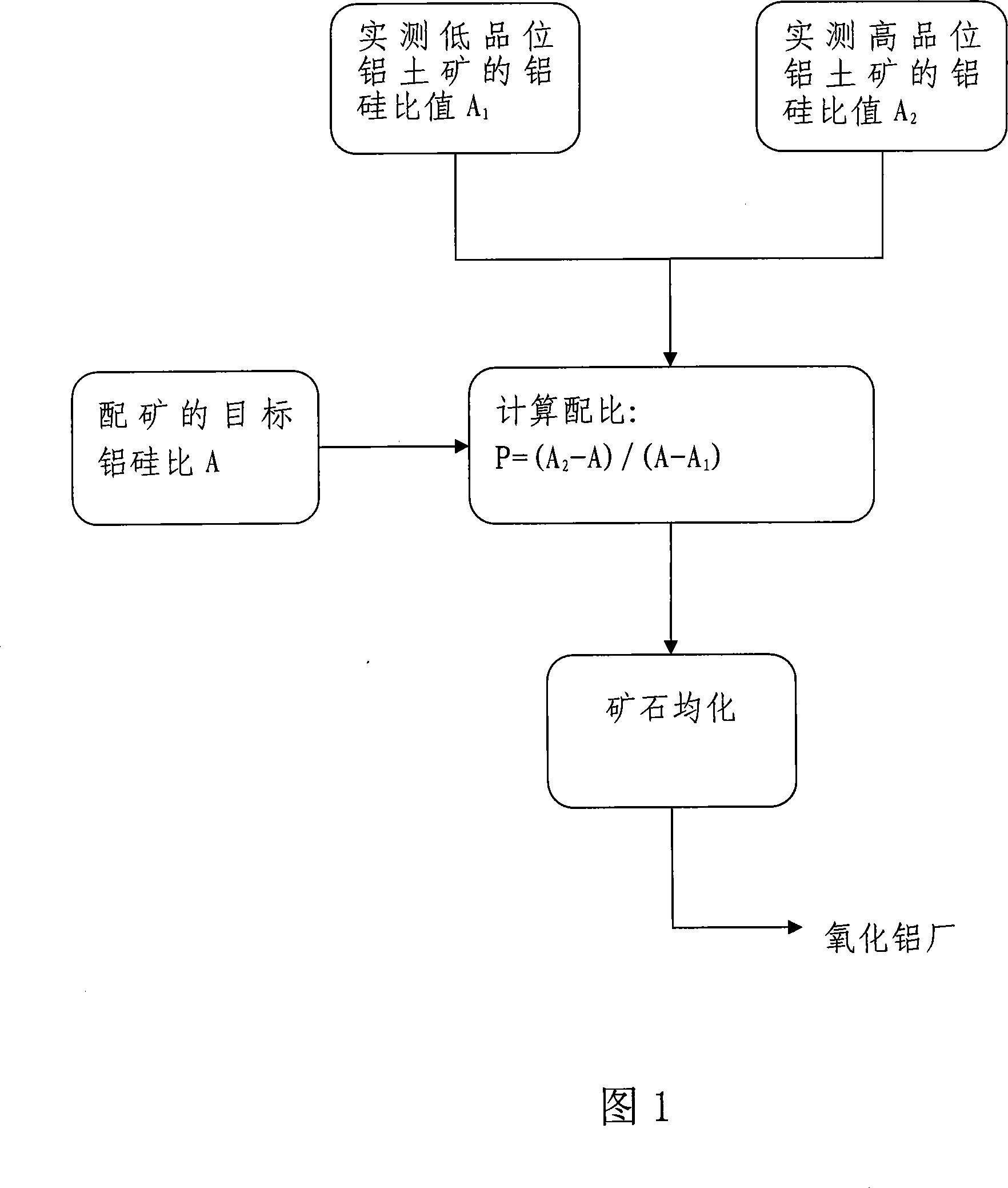

[0012] The present invention will be further described below by way of examples.

[0013] The measured bauxite grades of the concentrate heap of Pingguo Bauxite Mine on August 30, 2007 are shown in Table 1 below.

[0014] Concentrate pile number

Measured aluminum-silicon ratio

Remark

1

4.53

low grade ore

2

16.78

high grade ore

[0015] In the above table, A 1 =4.53,A 2 =16.78.

[0016] At that time, the Bayer method production process of the alumina factory required the target aluminum-silicon ratio of ore blending to be A=12.

[0017] The ratio of low-grade ore to high-grade ore is:

[0018] P=(A 2 -A) / (A-A 1 )=(16.78-12):(12-4.53)=6.78:8.53=1:1.26

[0019] According to the ratio of 1:1.26, the ore blending of low-grade and high-grade bauxite is carried out, and then homogenized and sent to the alumina plant for production, that is, the target aluminum-silicon ratio required for the production proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com