Maleic anhydride production technique

A maleic anhydride and production process technology, applied in the field of maleic anhydride production process, can solve problems such as unstable quality and low refining yield, and achieve high product quality, high utilization rate, and stable product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

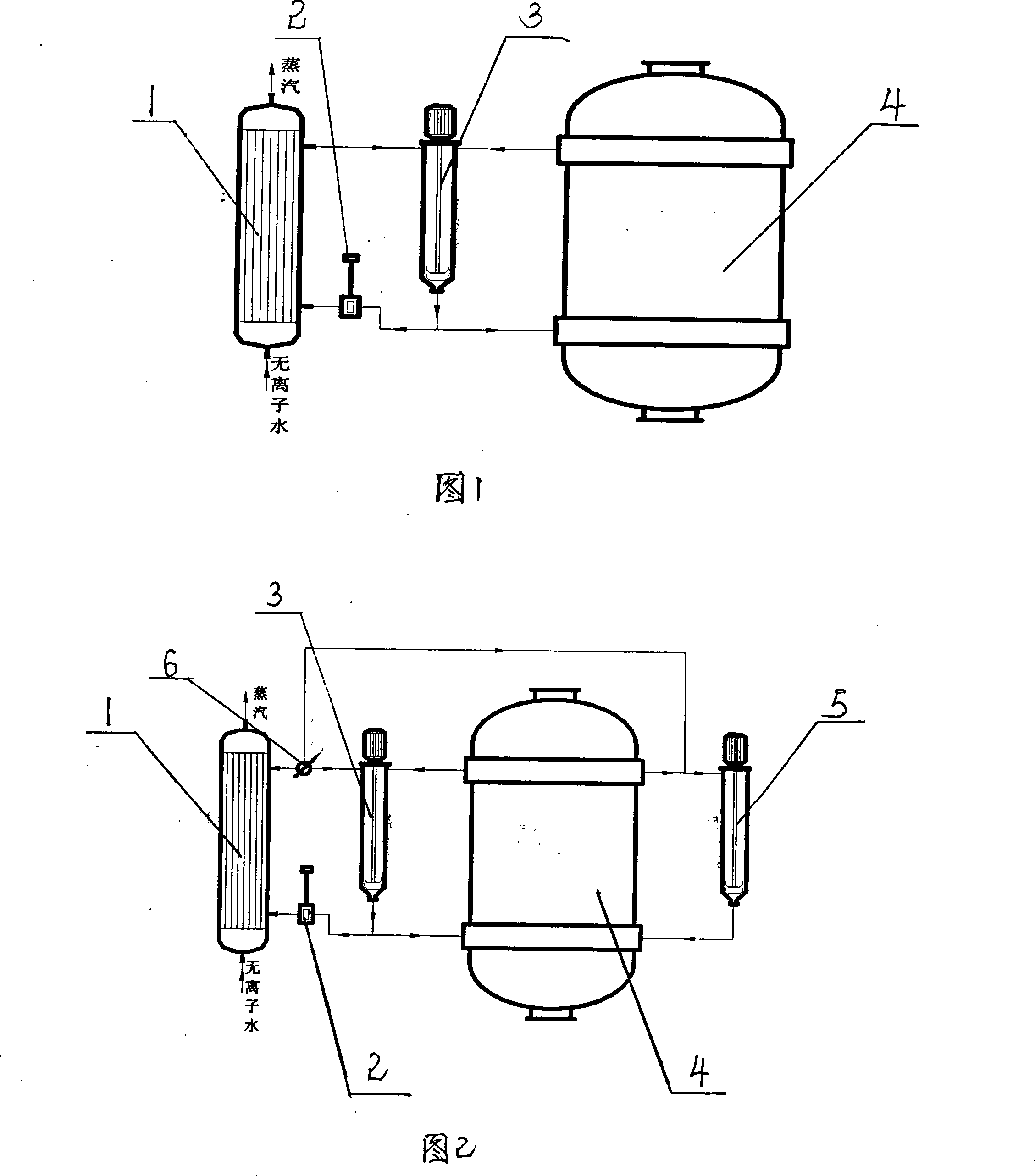

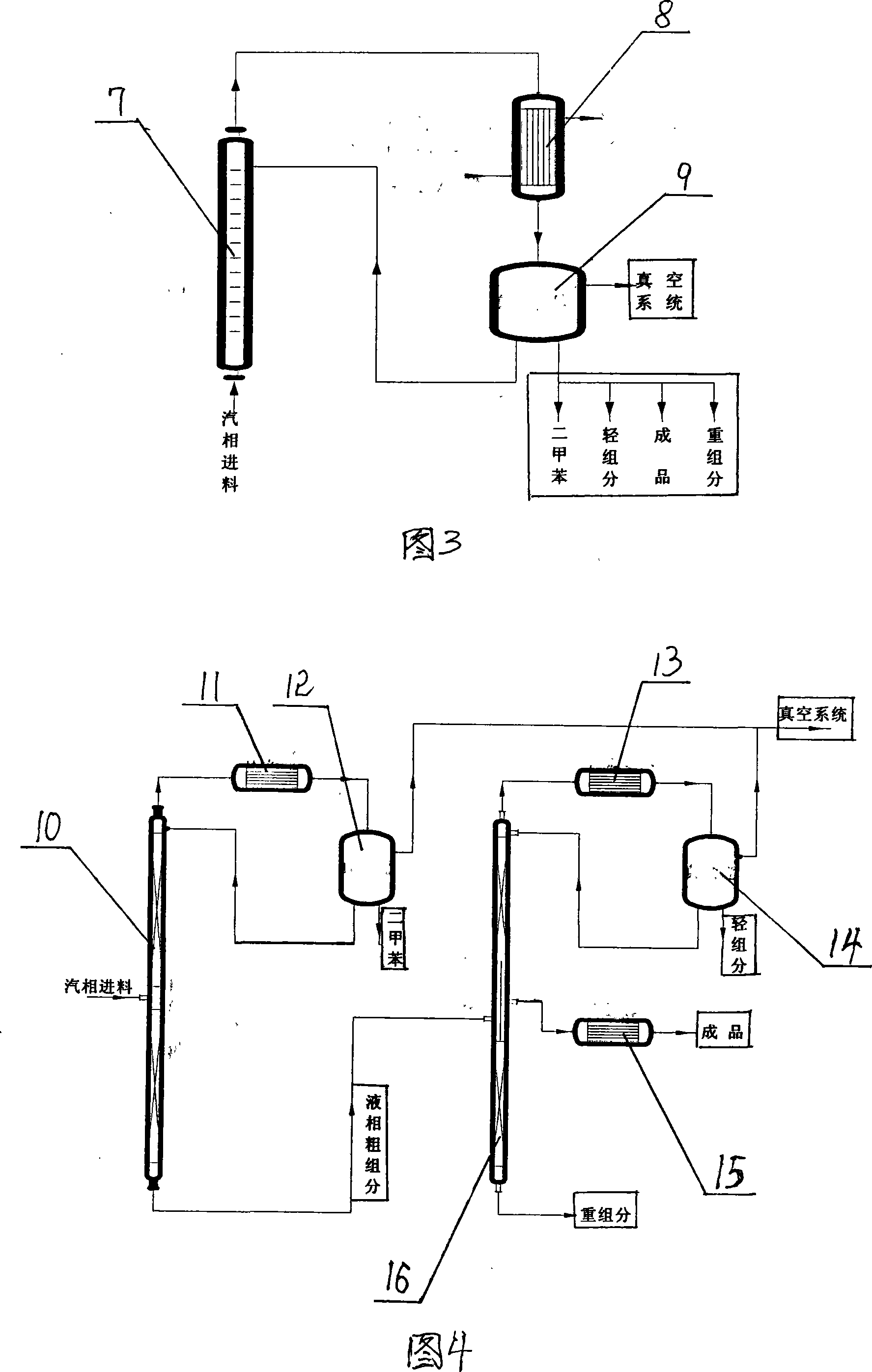

[0016] A maleic anhydride production process, comprising the following steps, fixed bed catalytic benzene oxidation, partial condensation, water absorption, azeotropic dehydration, rectification, (as shown in Figure 2) the benzene oxidation fixation used in the benzene oxidation reaction stage There are two axial flow pumps connected to the bed reactor. In the rectification stage, it is a continuous rectification process. (As shown in Figure 4) the acid water and crude anhydride produced by the oxidation reaction will first enter the middle of the desolventization tower after azeotropic dehydration. , and then the liquid-phase crude maleic anhydride separated from the lower part of the desolventization tower is sent to the middle part of the rectification tower, and the gas phase components obtained from the outlet of the middle part of the rectification tower are condensed by a condenser to obtain finished products.

[0017] The benzene oxidation fixed-bed reactor used in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com