High-speed four-jet air-jet loom

An air-jet loom, high-speed technology, applied in the direction of looms, textiles, textiles and papermaking, etc., can solve the problems of low weft insertion rate, unsuitable for weaving, not very clear opening, etc., to increase weft insertion rate and reduce breakage Warp ratio and the effect of expanding the weaving range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The high-speed four-jet air-jet loom of the present invention, its opening mechanism, weft insertion mechanism, warp let-off mechanism, coiling mechanism and other auxiliary mechanisms, etc., except for the following technical content, all can adopt the prior art. The most relevant existing technical features are combined below, and the technical features that the present invention contributes to the prior art are explained emphatically:

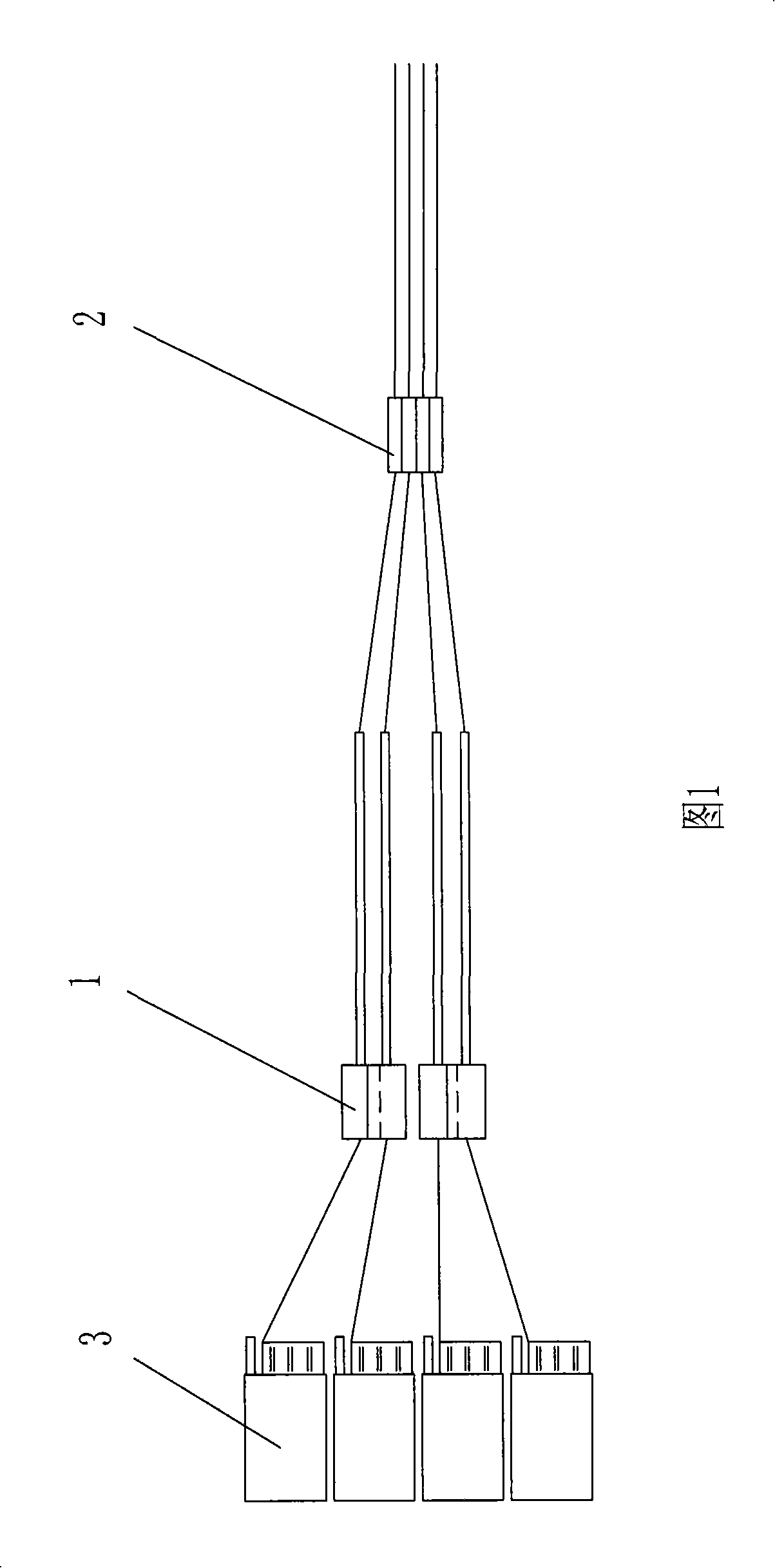

[0016] With reference to Fig. 1, the weft insertion mechanism in the present invention includes a pressure reducing valve, a high frequency valve and nozzles, the nozzles include four fixed nozzles 1 and one moving nozzle 2, and the four fixed nozzles 1 are arranged side by side on the weft feeder 3 The moving nozzle 2 is arranged in front of the fixed nozzle 1. The weft yarn on the weft feeder 3 passes through the fixed nozzle 1 and then passes through the moving nozzle 2. The fixed nozzle 1 and the moving nozzle 2 work together to ej...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com