Automatic speed regulation air compressor

An air compressor, automatic speed regulation technology, applied in the direction of machine/engine, mechanical equipment, liquid variable capacity machinery, etc., can solve the problem of energy saving, unable to automatically adjust the operation stop, etc., to achieve small vibration and reduce impact , the effect of running smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

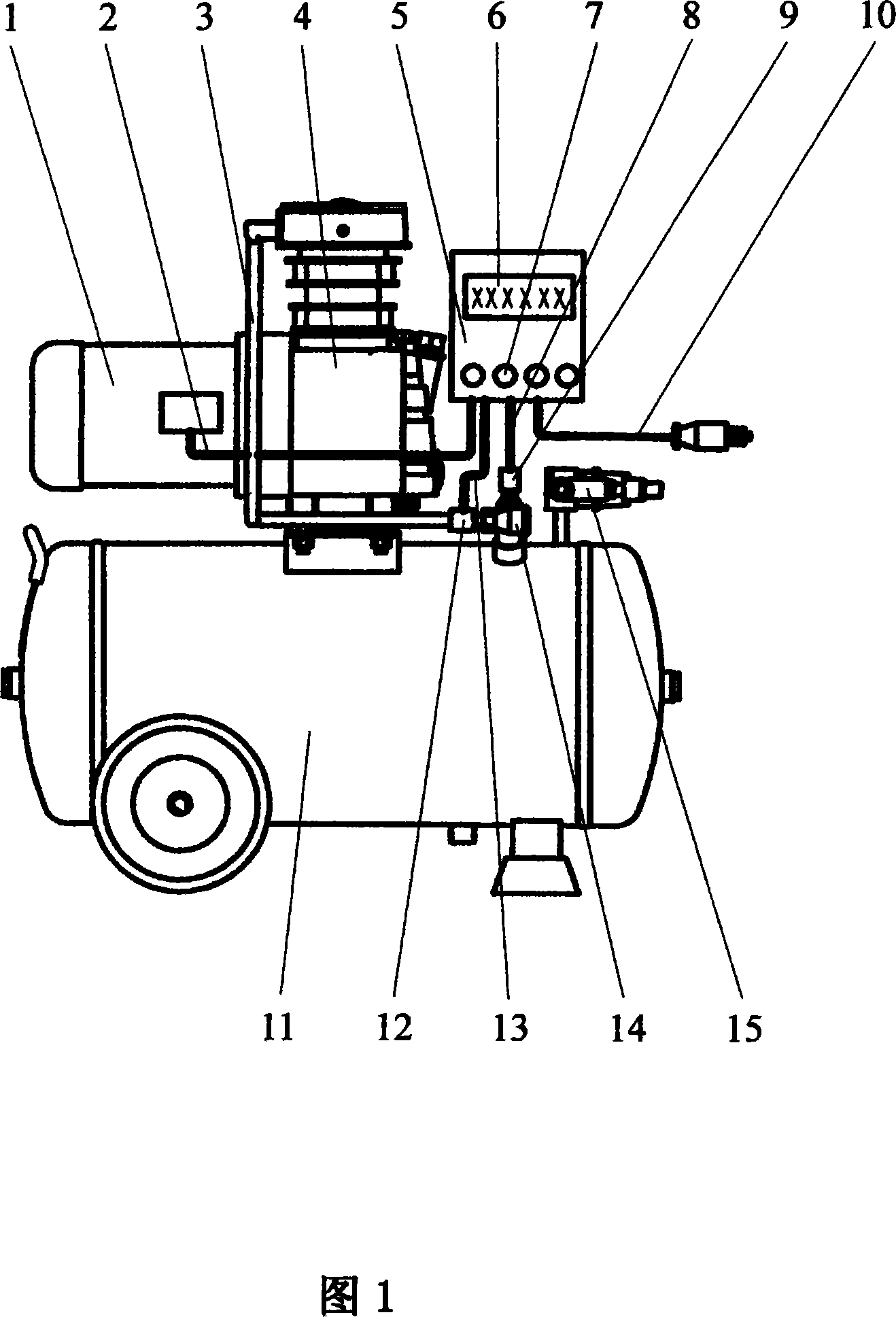

[0021] Embodiment 1 is to use a DC motor to drive the air compressor: the motor (1) adopts a DC motor, and the motor power supply input line (2) is connected to the controller (5); The three interfaces of the pipe are respectively connected to the air outlet of the gas storage tank (11), the pressure sensor (9), and the unloading valve (12); the pressure sensor signal line (8) of the pressure sensor (9) is connected to the controller (5); The air inlet of the unloading valve (12) is connected to the air compressor compressed air outlet pipe (3) of the air compressor (4), and the unloading valve (12) is

[0022] The unloading valve control line (13) is connected to the controller (5), (when the unloading valve (12) adopts an automatic unloading valve, the unloading valve control line (13) is omitted); the controller (5) is provided with a rectifier circuit, a DC Motor speed regulating circuit, pressure signal preset and pressure sensor signal comparison control circuit, switch ...

Embodiment 2

[0023] Embodiment 2 is to use the series excitation motor to drive the air compressor: the motor (1) adopts the series excitation motor, and the DC motor speed regulating circuit of the controller (5) is changed into a series excitation motor voltage speed regulating circuit. Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com