Manufacturing method with curvature thin wall stainless steel pipe fittings

A technology of bending parts and manufacturing methods, applied in the direction of pipe components, non-detachable pipe connections, pipes/pipe joints/pipe fittings, etc., can solve the problems of high machining cost and heavy product weight, and achieve low product cost and beautiful appearance , Guarantee the effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

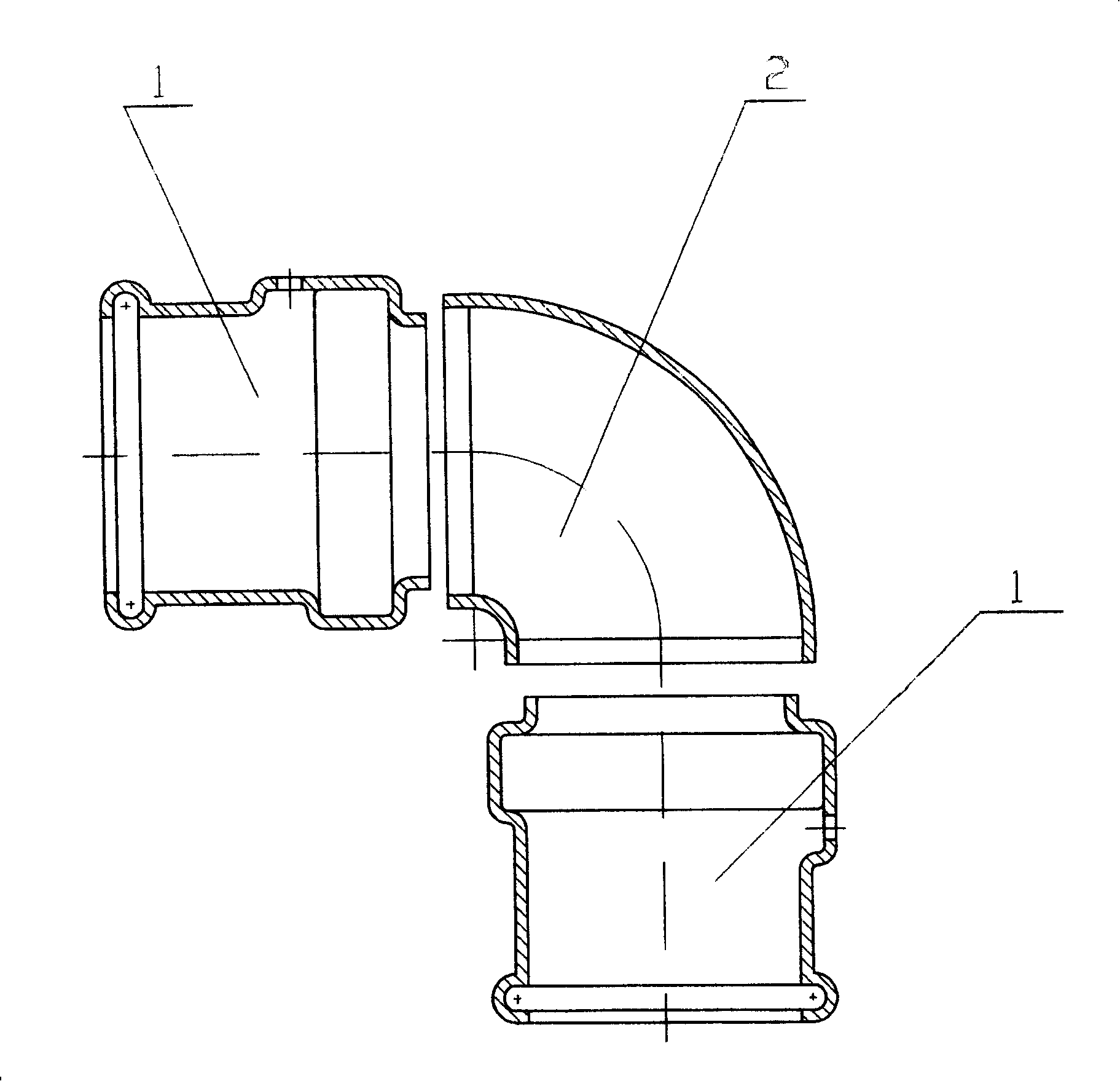

[0013] The socket part (1) adopts a thin-walled stainless steel pipe as a raw material, and is manufactured by pressure processing techniques such as expansion and compression forming. The curved part (2) is manufactured by a stainless steel precision casting process. Then, the socket parts (1) at both ends and the bent part (2) in the middle are welded into one body by a full-automatic argon arc welding machine. Since it is difficult to precision cast the curved part of the bridge as a whole, it is divided into two sections from the middle for precision casting, and then assembled and welded into one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com