Novel biomass solid particle analgesic reactor

A technology of pyrolysis reactor and solid particles, which is applied in the direction of biofuels, special forms of dry distillation, petroleum industry, etc., can solve the problem of uneven pyrolysis of the bed layer, poor thermal conductivity of biomass, and is not suitable for thermal treatment of biomass solid particles. Solve problems such as liquefaction, and achieve the effect of reliable work, strong versatility and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

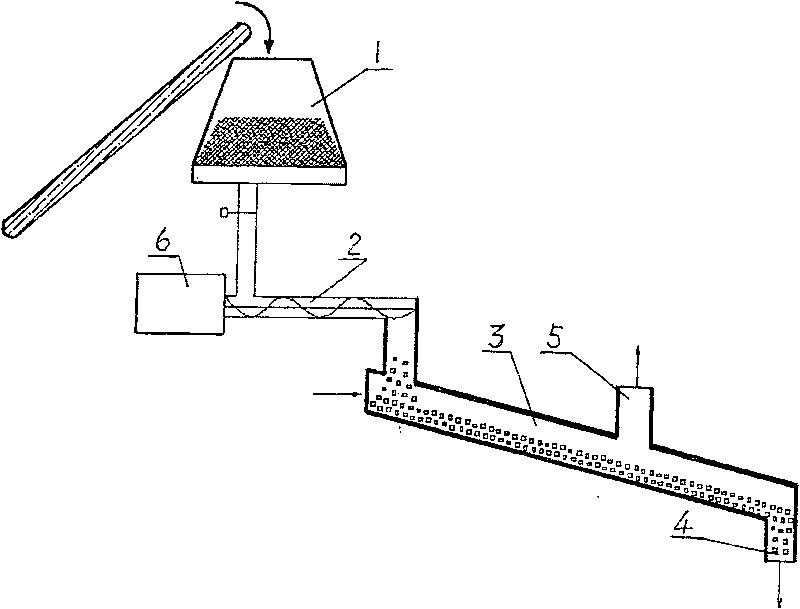

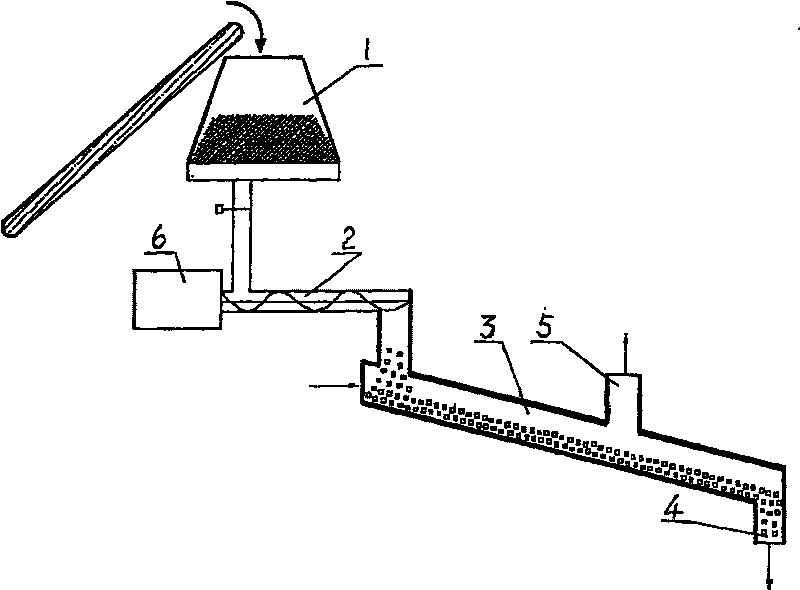

[0015] The new biomass solid particle pyrolysis reactor includes a barrel 1, a screw feeder 2 and a pyrolysis reactor 3. The barrel is connected to the screw feeder through a feed pipe and is located above the screw feeder. See figure 1 ;

[0016] The pyrolysis reactor 3 is a flat horizontal type, with a length of 800 millimeters, a width of 400 millimeters, and a height of 40 millimeters; the upper part of one end is connected to the screw feeder as the feed inlet, and the lower part of the other end is the pyrolysis charcoal outlet 4, There is a pyrolysis gas outlet 5 in the upper part of the middle; its inclination angle relative to the horizontal plane is adjustable, and the feed port is higher than the pyrolysis carbon outlet; the upper end of the bottom of the pyrolysis reactor 3 is provided with an electric vibrator.

[0017] Assuming that the particle size of biomass solid particles is 2mm and the bulk density ρ is 100kg / m 3 , the feed rate is 100kg / h; if the pyrolysi...

Embodiment 2

[0020] The pyrolysis reactor 3 has a length of 400 mm, a width of 200 mm, and a height of 20 mm;

[0021] If the pyrolysis reactor is placed at an inclination of 45°, the vibration frequency is 200Hz, and the bottom wall heating temperature is 600°C, then this situation can meet the above-mentioned process requirements for pyrolysis and liquefaction of biomass particle materials.

[0022] Others are with embodiment 1.

Embodiment 3

[0024] The length of the pyrolysis reactor is 600 mm, the width is 300 mm, and the height is 30 mm;

[0025] If the pyrolysis reactor is placed at an inclination of 20°, the vibration frequency is 400Hz, and the heating temperature of the bottom wall is 500°C, then this situation can meet the above-mentioned technological requirements for the pyrolysis and carbonization of biomass particulate materials; if the pyrolysis reactor is placed at an inclination of 30° , the vibration frequency is 300Hz, and the heating temperature of the bottom wall is 900°C, then this situation can meet the above-mentioned process requirements for the pyrolysis and gasification of biomass particle materials; if the pyrolysis reactor is placed at an inclination of 40°, the vibration frequency is 200Hz, The heating temperature is 600°C, which can meet the above-mentioned process requirements for pyrolysis and liquefaction of biomass granular materials.

[0026] Others are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com