Pyrolysis melting kiln for manufacturing vitrified ceramsite through biomass heat source

A biomass and kiln technology, applied in the direction of furnaces, furnace types, lighting and heating equipment, etc., can solve problems such as polluting the environment, large volume, and hazardous waste pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

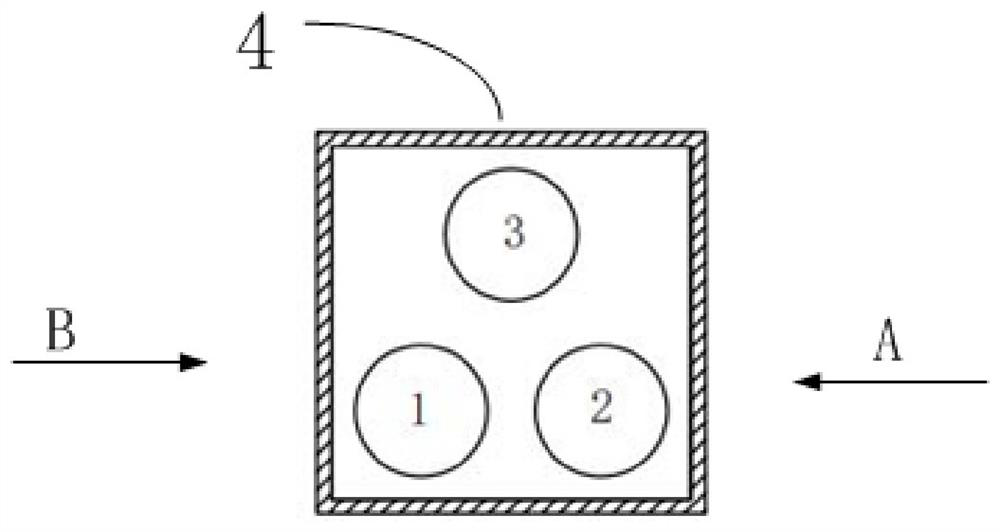

[0080] Implementation mode one: if figure 1 As shown, the kiln shell 4 is a cuboid, the pyrolysis reaction kettle 1 is on one side of the firing rotary kiln 2 , and the drying rotary kiln 3 is located above the middle of the pyrolysis reaction kettle 1 and the firing rotary kiln 2 .

Embodiment approach 2

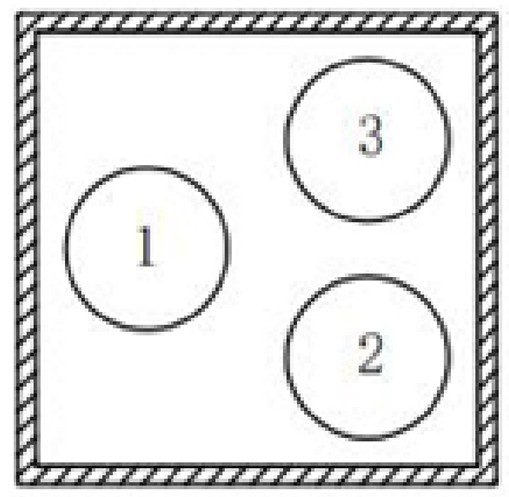

[0081] Implementation mode two: if figure 2 As shown, the kiln shell 4 is a cuboid, the drying rotary kiln 3 is located directly above the firing rotary kiln 2 , and the pyrolysis reaction kettle 1 is on one side of the firing rotary kiln 2 and drying rotary kiln 3 .

Embodiment approach 3

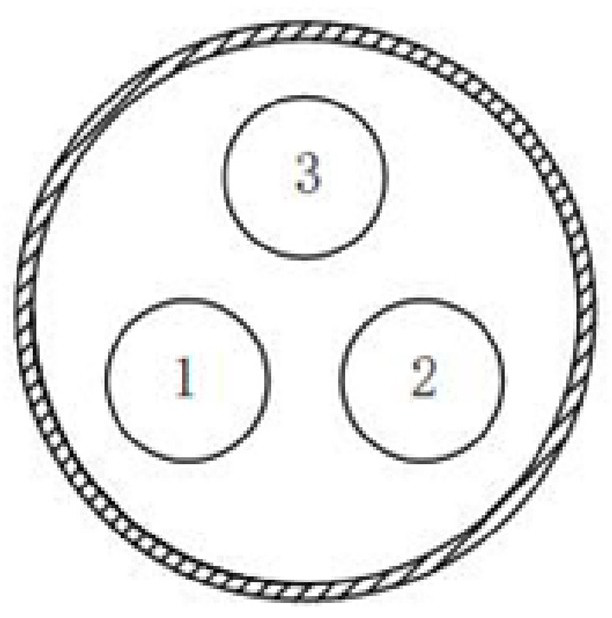

[0082] Implementation mode three: if image 3 As shown, the kiln shell 4 is a cylinder, the pyrolysis reaction kettle 1 is on one side of the firing rotary kiln 2 , and the drying rotary kiln 3 is located above the middle of the pyrolysis reaction kettle 1 and the firing rotary kiln 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com