Apparatus and method for producing energy at a pulp mill

A technology in the pulp and paper industry, applied in the field of waste liquid recovery boilers, can solve problems such as superheater corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

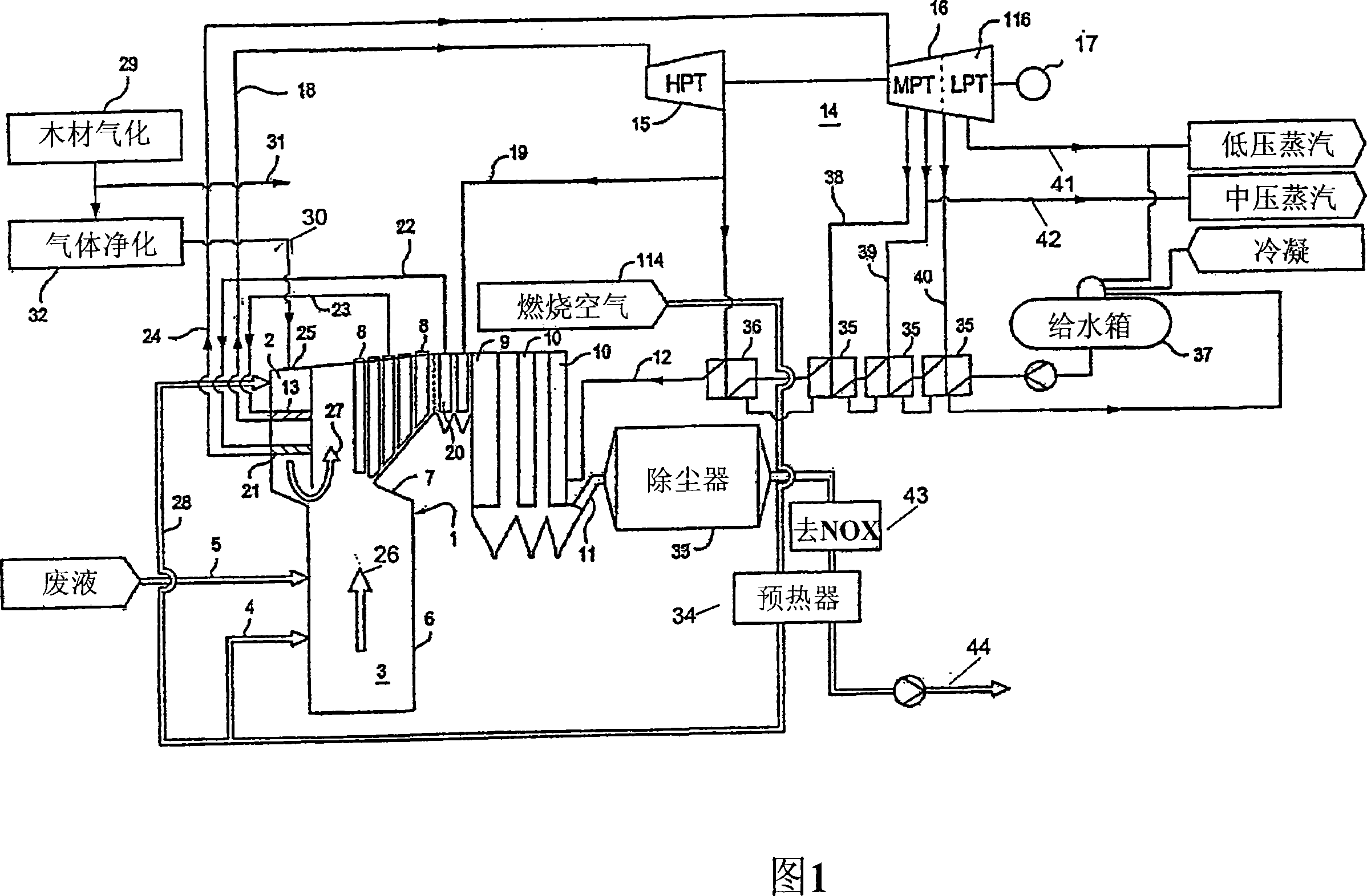

[0075] FIG. 1 shows a furnace 3 of a typical recovery boiler 1 , such as a kraft pulp recovery boiler for burning black liquor, which has a structure formed by water-cooled tube walls 6 . The water-steam mixture produced in this way is superheated by a conventional superheater 8 located partly in the "nose" hood above the furnace. The heat of the flue gases 26 produced during the combustion of the black liquor is recovered in the superheater 8 . Typically, boiler tube bundles 9 and economizers 10 act as post heating surfaces in the boiler. After the superheater, the flue gas is directed into the boiler tube bundle 9 and the economizer 10 .

[0076] The recovery boiler 1 comprises a cavity 2 which can be arranged close to the upper part of the boiler wall. The flue gas 26 produced by the furnace 3 of the recovery boiler flows upwards from the cavity 2 and through the inflow opening. Combustion air 4 is fed into the furnace to facilitate combustion, usually at several levels,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com