Industrialized Technique for sea water desalination and pretreatment

A process method and pretreatment technology, applied in seawater treatment, flocculation/sedimentation water/sewage treatment, sterilization/microdynamic water/sewage treatment, etc. The effect of preventing the reduction of drug efficacy and improving the precipitation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

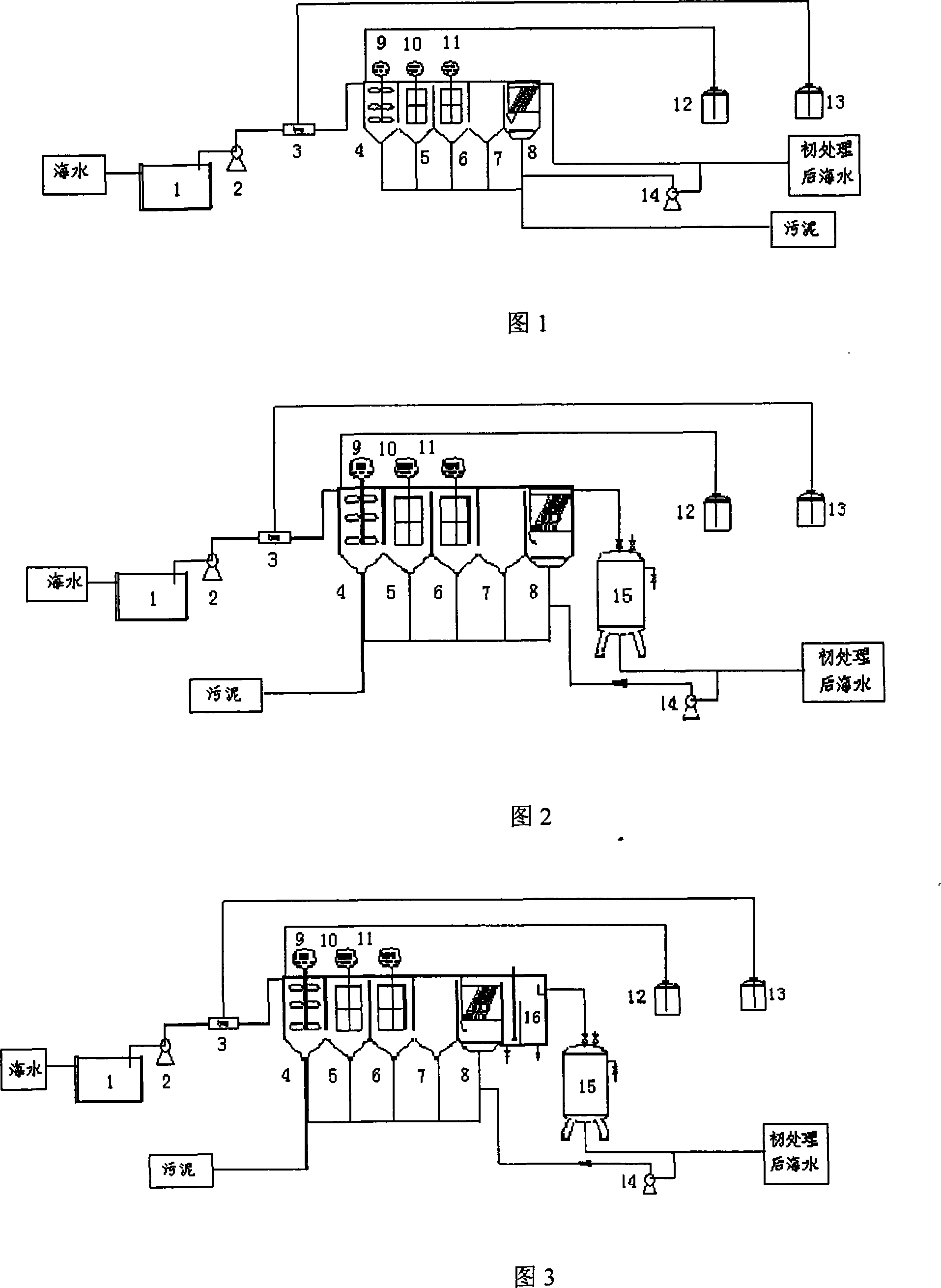

Embodiment 1

[0031]The seawater from the natural sedimentation tank is lifted by the seawater lift pump, mixed with the flocculant (polyferric sulfate) measured by the metering pump from the dosing system in the jet, and then enters the three-stage mechanical stirring flocculation reaction ramp sedimentation tank, the flocculant The amount added is 30mg / L. The fungicide is metered by the metering pump and directly poured into the mechanical stirring mixing tank, and the amount of the fungicide added is 4mg / L. The stirring speed of the mixing tank is 165r / min, the stirring speed of the flocculation tank is 40r / min and 18r / min respectively, and the total residence time of the mixing flocculation tank is 25min. The residence time of the inclined plate sedimentation tank is 30 minutes, and the mud discharge time is 10 hours. The supernatant of the inclined plate sedimentation tank overflows to the air flotation tank, and the effluent of the air flotation tank overflows the gravity sand filter...

Embodiment 2

[0033] The seawater from the natural sedimentation tank is lifted by the seawater lift pump, mixed with the flocculant (ferric chloride) measured by the metering pump from the dosing system in the jet, and then enters the three-stage mechanical agitation flocculation reaction inclined plate sedimentation tank, flocculation Dose addition is 40mg / L. The fungicide is metered by the metering pump and directly poured into the mechanical stirring mixing tank, and the amount of the fungicide added is 5mg / L. 1. The stirring speed of the mixing tank is 180r / min, the stirring speed of the flocculation tank is 50r / min and 15r / min respectively, and the total residence time of the mixing flocculation tank is 20min. The residence time of the inclined plate sedimentation tank is 25 minutes, and the mud discharge time is 12 hours. The supernatant of the inclined plate sedimentation tank overflows to the purified seawater storage tank. Product water turbidity 40.3%. See Figure 2.

Embodiment 3

[0035] The seawater from the natural sedimentation tank is lifted by the seawater lift pump, mixed with the flocculant (polyferric sulfate) measured by the metering pump from the dosing system in the jet, and then enters the three-stage mechanical stirring flocculation reaction ramp sedimentation tank, the flocculant The amount added is 25mg / L. The fungicide is metered by the metering pump and directly poured into the mechanical stirring mixing tank, and the amount of the fungicide added is 3mg / L. 1. The stirring speed of the mixing tank is 150r / min, the stirring speed of the flocculation tank is 35r / min and 12r / min respectively, and the total residence time of the mixing flocculation tank is 30min. The residence time of the inclined plate sedimentation tank is 40 minutes, and the mud discharge time is 18 hours. The supernatant of the inclined plate sedimentation tank overflows to the gravity sand filter. The turbidity of sand filter effluent is less than 1.5NTU, and the rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com