Infrared transparent gallate glass

A gallate and infrared-transmitting technology applied in the field of optical glass to achieve high transmittance and wide transmission range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

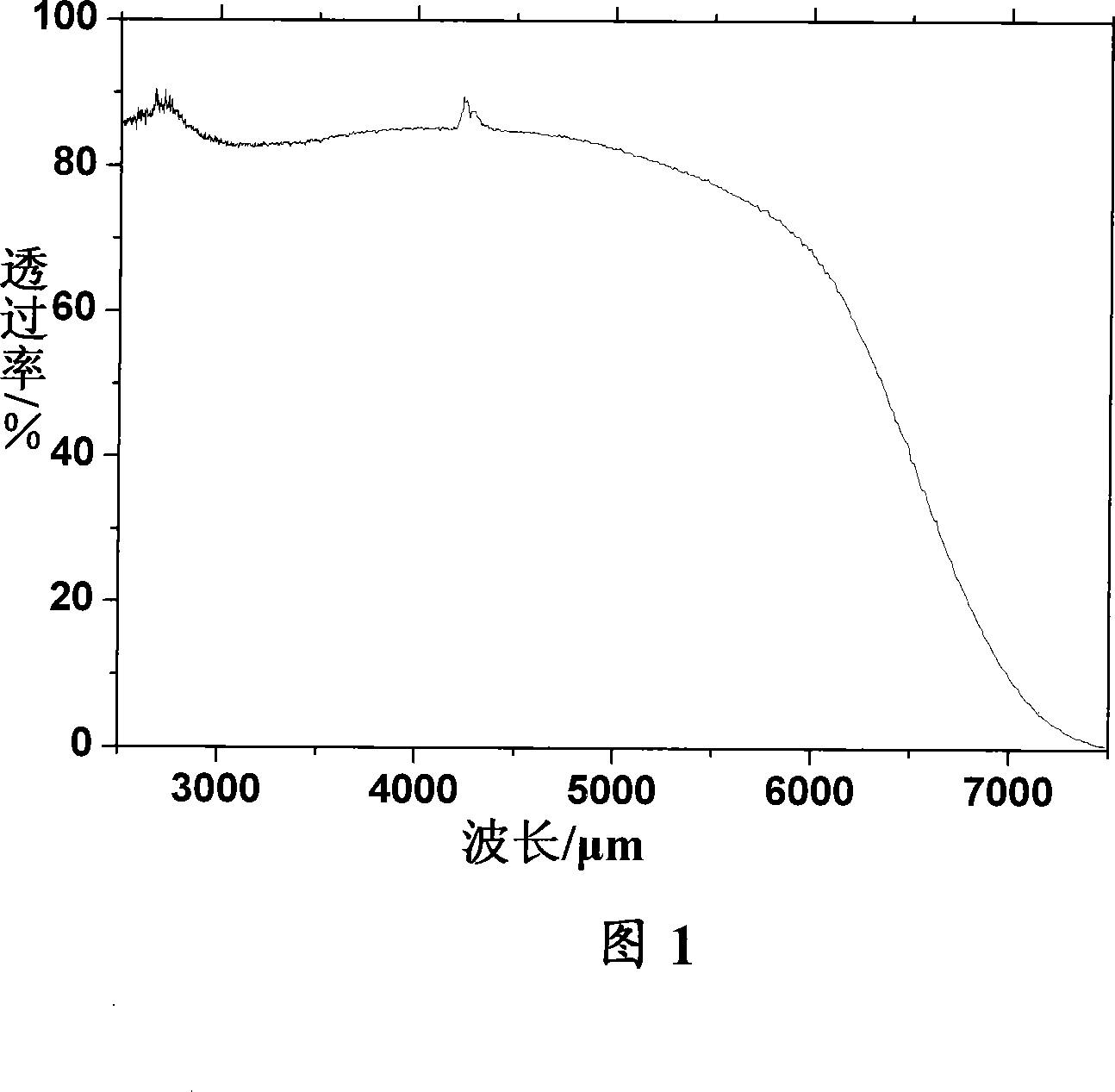

[0035] This embodiment adopts mole percentage to form 30Ga 2 o 3 +35CaO+20BaO+15BaF 2, Prepare 1000g of powder, melt in an electric furnace at 1350°C for 2 hours, pass dry air into the melt, then lower the temperature and keep it at 1250°C for 1 hour, stir for 1 hour to make the glass uniform. The melt is poured on a preheated template, annealed at 630° C. for 2 hours to eliminate the stress in the glass, and then slowly cooled to room temperature to obtain a gallate infrared-transmitting glass. Table 1 lists the properties of the glass in this embodiment. It shows that the glass of this example has good physical properties. Fig. 1 is the transmission spectrum of the glass of this embodiment, which has a very wide transmission range and high transmittance (uncoated), and the hydroxyl absorption near 3.3 μm is small, which is a kind of glass with good application prospects. infrared material. The material has good physical and chemical properties, as shown in Table 2:

[0...

Embodiment 2

[0038] Example 2, Example 3, Example 4, Example 5

[0039] Table 3 Example 2, Example 3, Example 4, Example 5 Weigh each ingredient to prepare 100 grams of powder, melt it in an electric furnace at 1350-1450 ° C for 3 hours, and pass it into the melt Dry the air, then keep it at 1250-1350°C and stir for 3 hours to make the glass uniform. The melt is poured on a preheated template, cooled rapidly to about 640°C, at T g Annealed at around temperature for 2 hours, then cooled slowly to room temperature.

[0040] The test of glass of the present invention shows that:

[0041] The glass can be used as a transparent multi-band window material with high transmittance to visible light and mid-infrared light at the same time.

[0042] The glass has a very small absorption coefficient in the vicinity of 3.0 μm due to hydroxyl groups.

[0043] The glass is a visible-infrared optical material that is stable, easy to manufacture in large sizes and complex shapes, has high optical unifo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com