Pixel structure capable of avoiding black-white point flickering after laser repairing

A pixel structure and semiconductor technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of flicker and reduce the image display quality of thin film transistor liquid crystal displays, and achieve the effect of improving repair quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

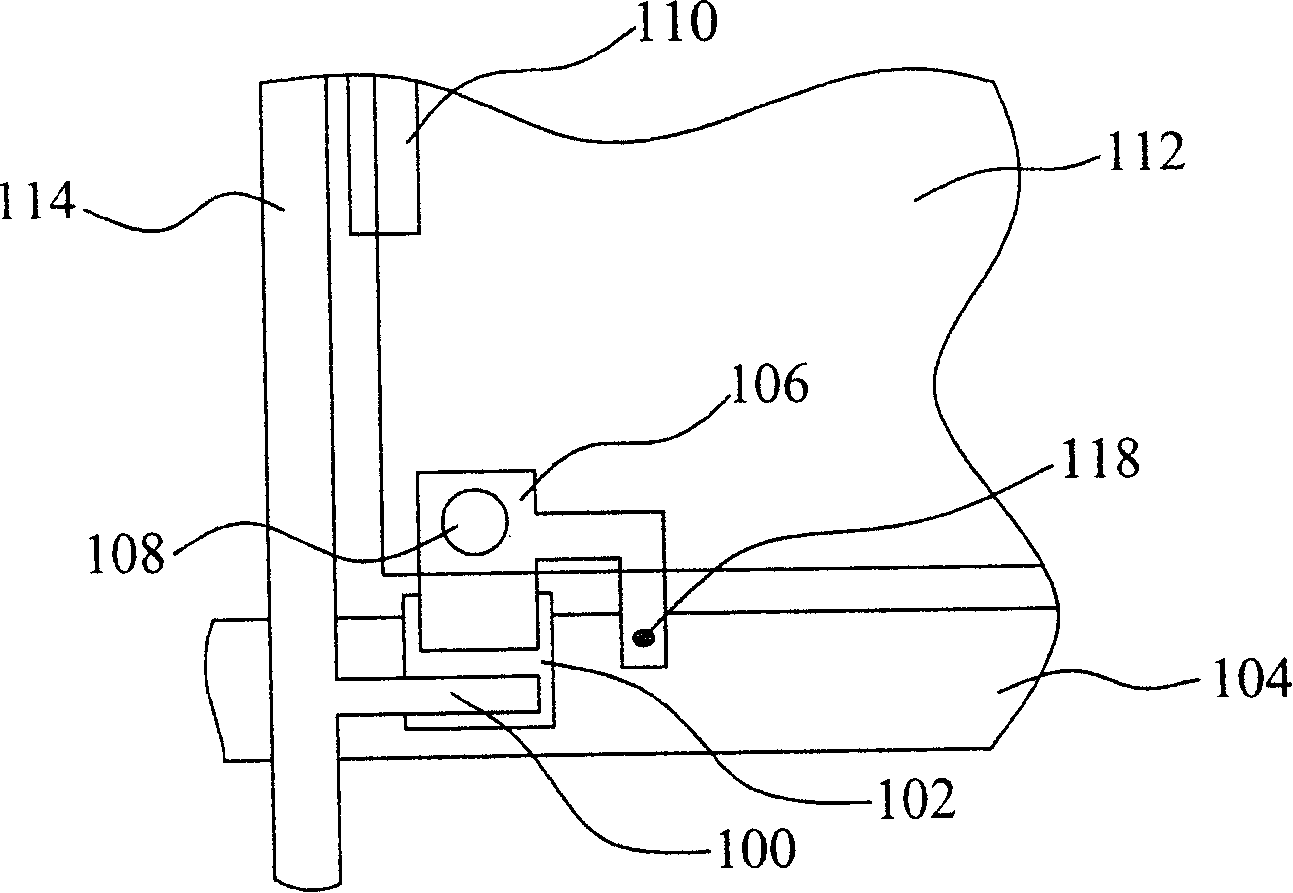

[0033] Figure 3AIt is a partial top view of the laser repaired pixel structure in the first embodiment of the present invention. The pixel of the thin film transistor array substrate has a multi-layer structure, and has two metal layers of a gate electrode layer and a source / drain electrode layer. The gate electrode The layer includes a gate line 304, a storage capacitor line 310 and a first floating metal 316. The gate line 304 is arranged along a row, the storage capacitor line 310 transmits a common voltage Vcom, and the source / drain electrode layer Including a source line 314, a source electrode 300 and a drain electrode 306, the source line 314 transmits the source signal to the source electrode 300, the source electrode 300 and the drain electrode 306 are respectively connected to a first semiconductor electrode 302 Partially overlapping, the gate line 304 has a gate electrode (not shown) located below the first semiconductor electrode 302 , and the gate signal is trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com