Method for quickly determining trinitrotoluene or hexogen in solution

A technology for rapid determination of trinitrotoluene, which is applied in the field of ion mobility spectrometer determination, can solve the problems that the content is difficult to accurately determine and cannot be suitable for rapid on-site analysis, etc., and achieves the effects of accurate quantification and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

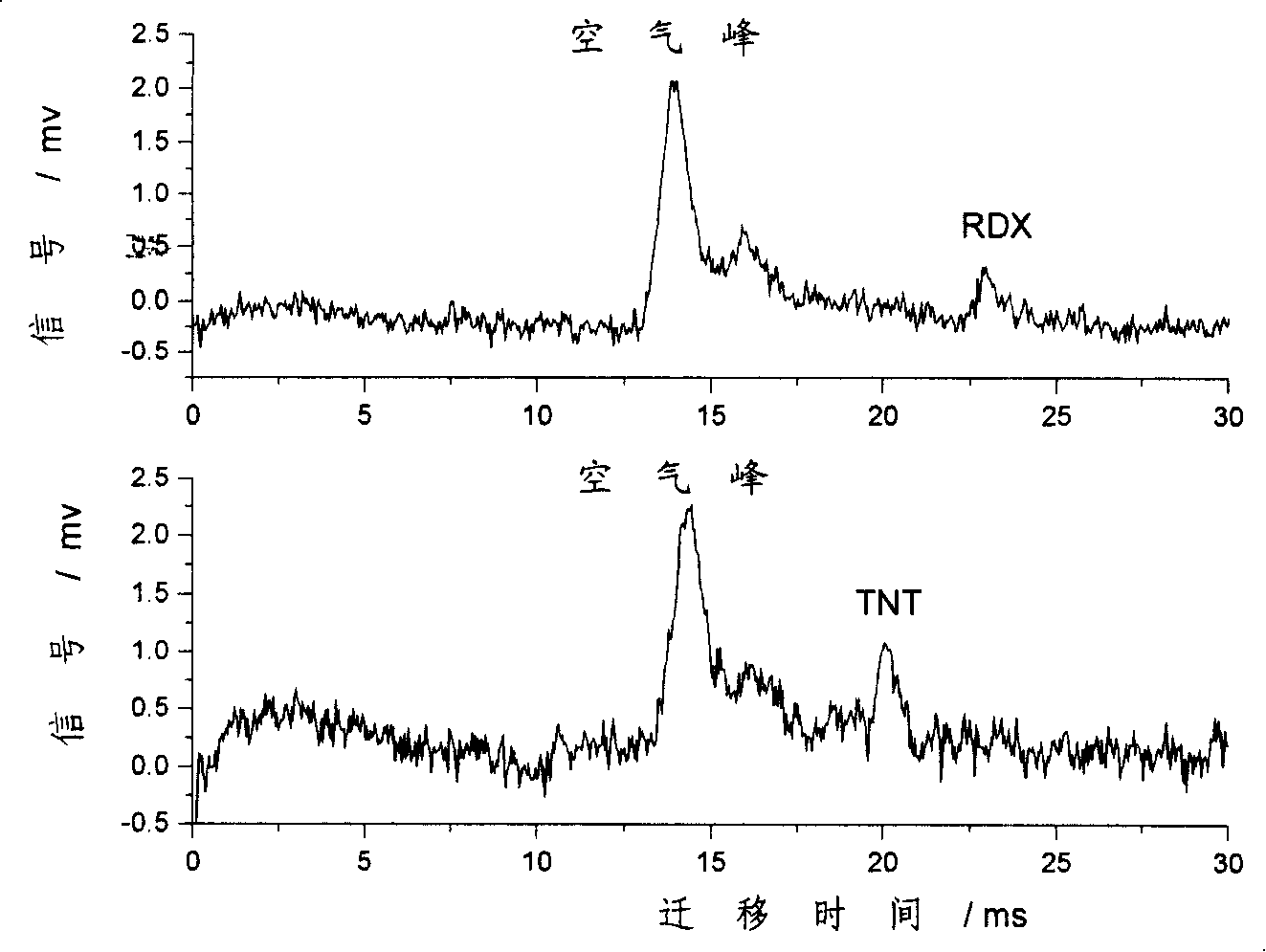

[0015] After weighing a certain amount of solid TNT with an analytical balance, prepare a 1 mg / mL TNT solution with analytical pure acetone. Take this solution and dilute it 100 times to a 10 μg / mL solution. Take 1uL of this solution, that is, 10ngTNT, drop it on the sample paper, heat it to about 200°C for thermal analysis, inject the carrier gas into the ion mobility spectrometer for quantitative detection, and obtain a signal of 1.0mV. The measured TNT spectrum is shown in figure 1 . The conditions for the quantitative determination of ion mobility spectrometry are: the ion source is 10mCi 63 Ni, the transfer tube length is 10cm, the transfer electric field is -280V / cm, the ion gate opening time is 0.5ms, the cycle is 50ms, the carrier gas flow rate is 100mL / min, the drift flow rate is 300mL / min, and the test temperature is 100°C-150°C , and the injection temperature was 200°C.

Embodiment 2

[0017] After weighing a certain amount of solid RDX (RDX) with an analytical balance, prepare a 1 mg / mL RDX solution with analytical pure acetone. Take this solution and dilute it 100 times to a 10 μg / mL solution. Take 1uL of this solution, that is, 10ngRDX, drop it on the sample paper, heat it to about 200°C for thermal analysis, and quantitatively detect it by injecting the carrier gas into the ion mobility spectrometer, and obtain a signal of 0.3mV. The measured RDX spectrum is shown in figure 1 . The conditions for the quantitative determination of ion mobility spectrometry are: the ion source is 10mCi 63 Ni, the transfer tube length is 10cm, the transfer electric field is -280V / cm, the ion gate ion gate opening time is 0.5ms, the cycle is 50ms, the carrier gas flow rate is 100mL / min, the drift flow rate is 300mL / min, and the test temperature is 100℃- 150°C, and the injection temperature is 200°C.

Embodiment 3

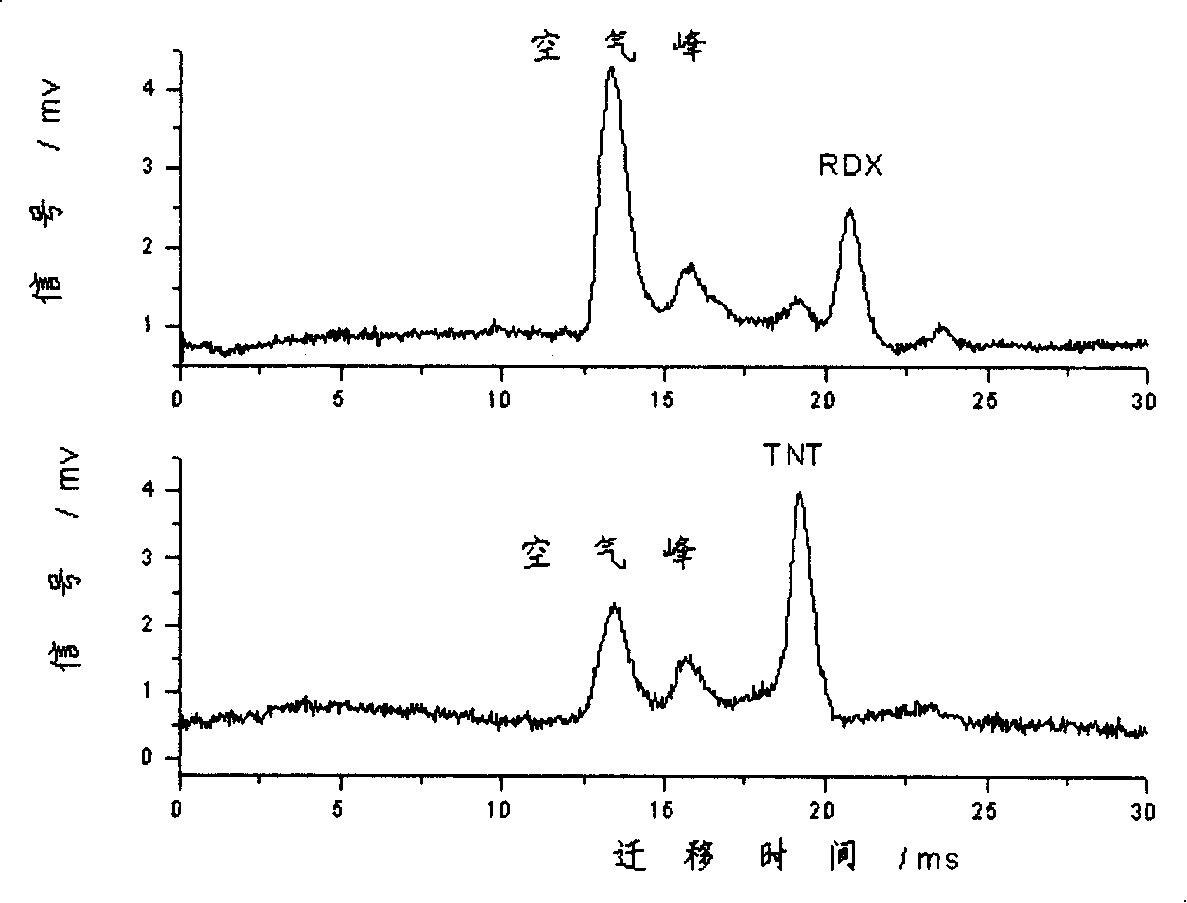

[0019] After weighing a certain amount of solid TNT with an analytical balance, prepare a 1 mg / mL TNT solution with analytical pure acetone. Take 100uL of this solution, that is, 100ugTNT, drop it on the sample paper, heat it to about 200°C for thermal analysis, and quantitatively detect it by injecting the carrier gas into the ion mobility spectrometer, and obtain a signal of 4.0mV. The measured TNT spectrum is shown in figure 2 . The conditions for the quantitative determination of ion mobility spectrometry are: the ion source is 10mCi 63 Ni, the transfer tube length is 10cm, the transfer electric field is -280V / cm, the ion gate ion gate opening time is 0.5ms, the cycle is 50ms, the carrier gas flow rate is 100mL / min, the drift flow rate is 300mL / min, and the test temperature is 100℃- 150°C, and the injection temperature is 200°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com