Metal-insulator-metal capacitor manufactured using etchback

A capacitor and insulator technology, applied in the field of metal-insulator-metal capacitors manufactured by etch back, can solve the problems of reducing yield, restricting use, and high leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

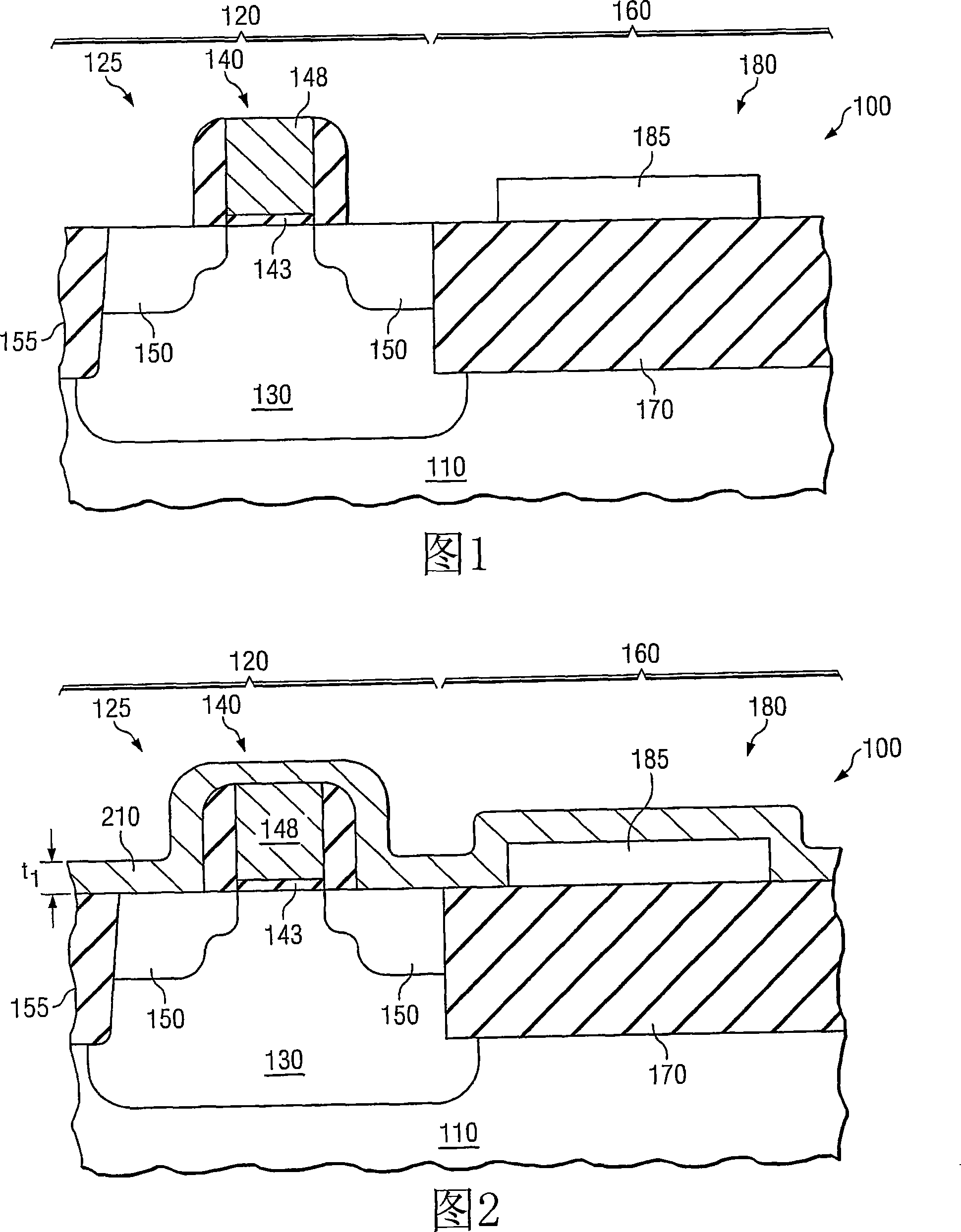

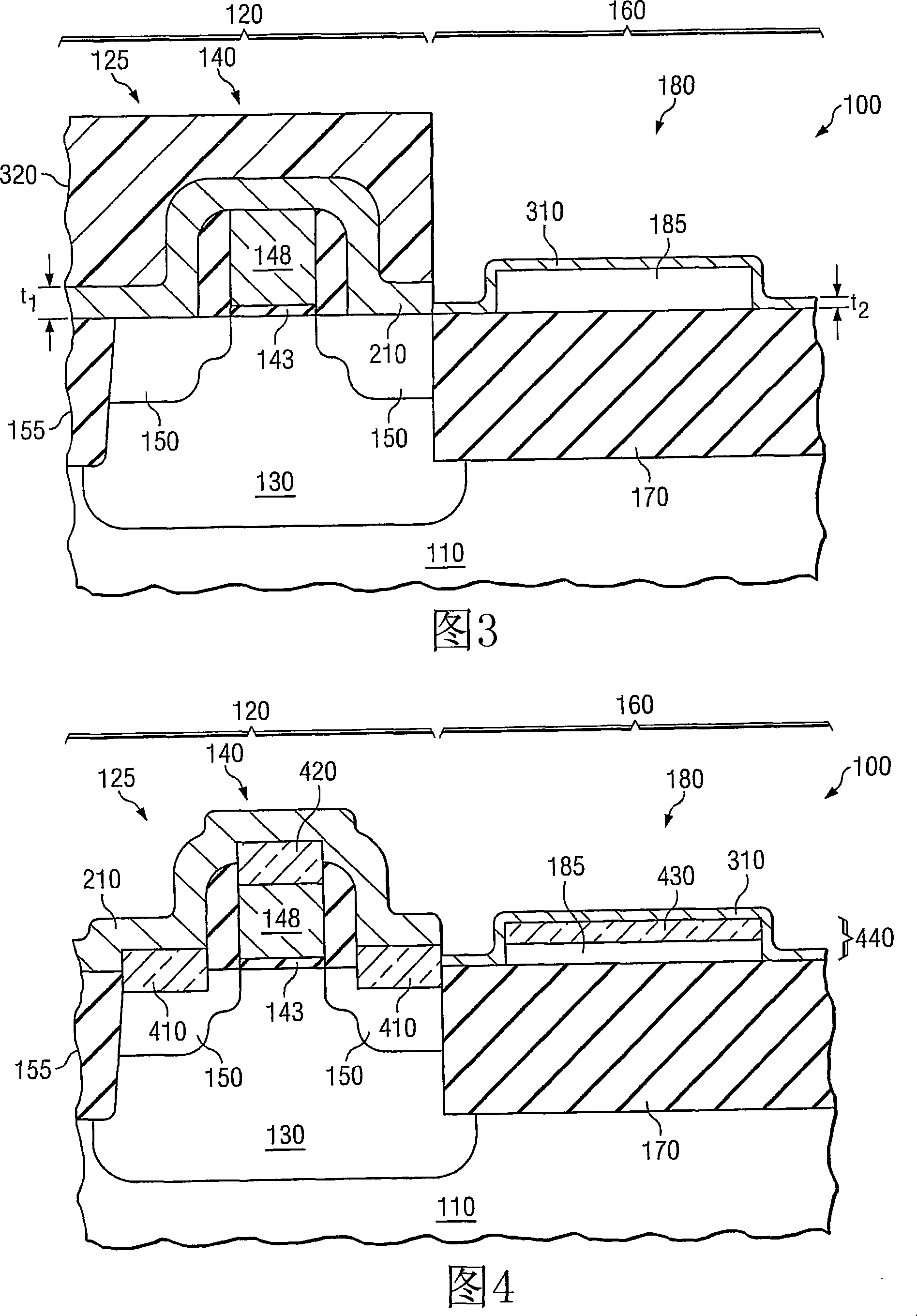

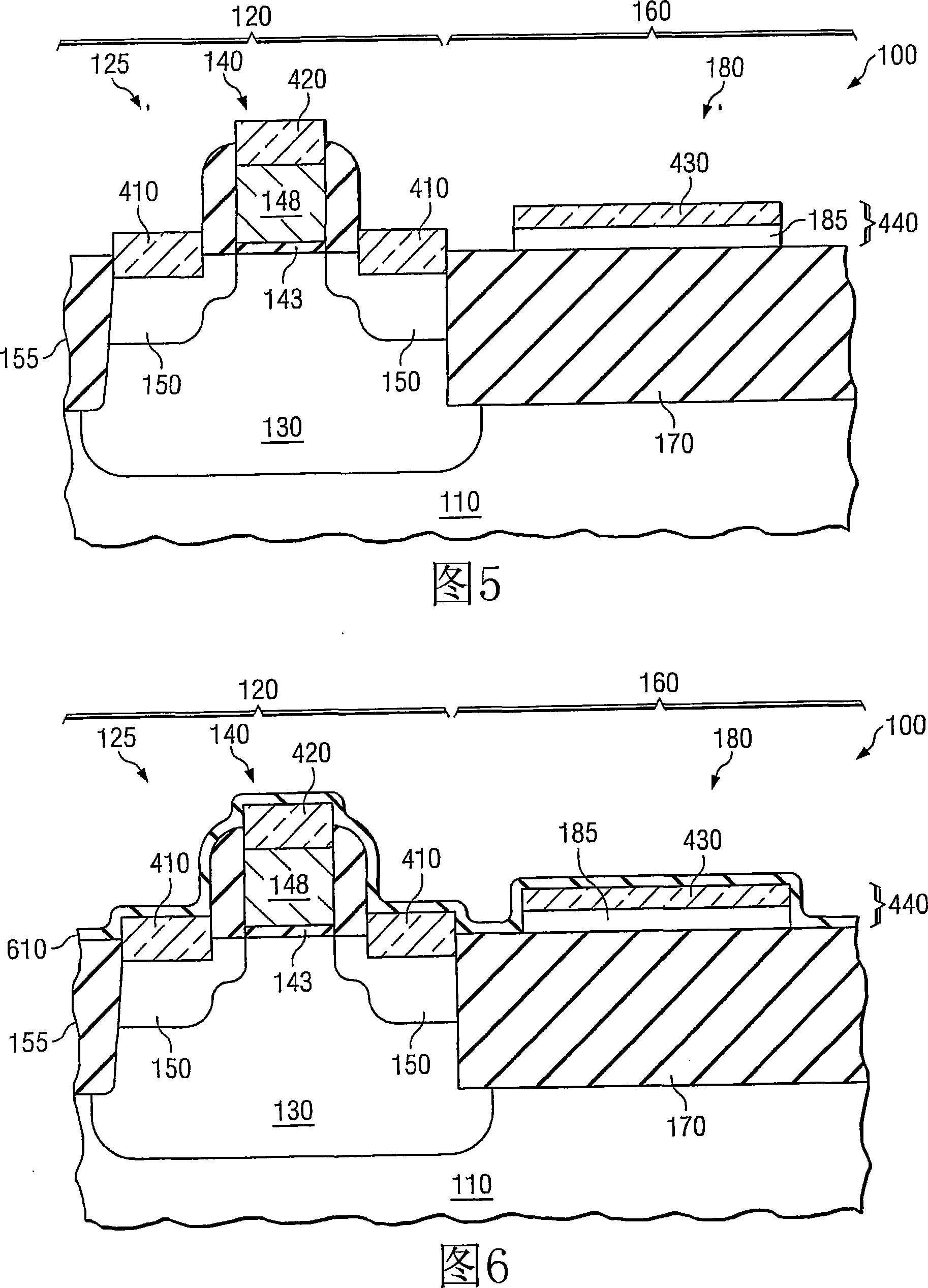

[0011] In connection with the present invention, it has been recognized that current leakage is largely affected by the thickness of a portion of the bottom electrode of a metal-insulator-metal (MIM) capacitor. In particular, it has been found that increasing the thickness of the silicided refractory metal layer in the bottom electrode results in increased roughness at the interface between the bottom electrode and the insulating layer located thereon. It is also believed that the number of positive charge traps present at rough interfaces is increased compared to smooth interfaces. Both the increased number of positive charge traps at the interface and the variable thickness of the electrodes are believed to increase the likelihood that electrons will leak through the capacitor. It was also recognized that the thickness of the refractory metal layer used to form at least a portion of the bottom electrode can be reduced, thus reducing current leakage. However, there are sourc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com