Method for producing leadless colored glaze

A kind of glass and ultra-clear glass technology, applied in the field of decorative glass building materials, can solve the problems of environmental pollution, endangering the health of workers, and the inability to use daily necessities and catering containers, and achieve the effect of avoiding lead poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

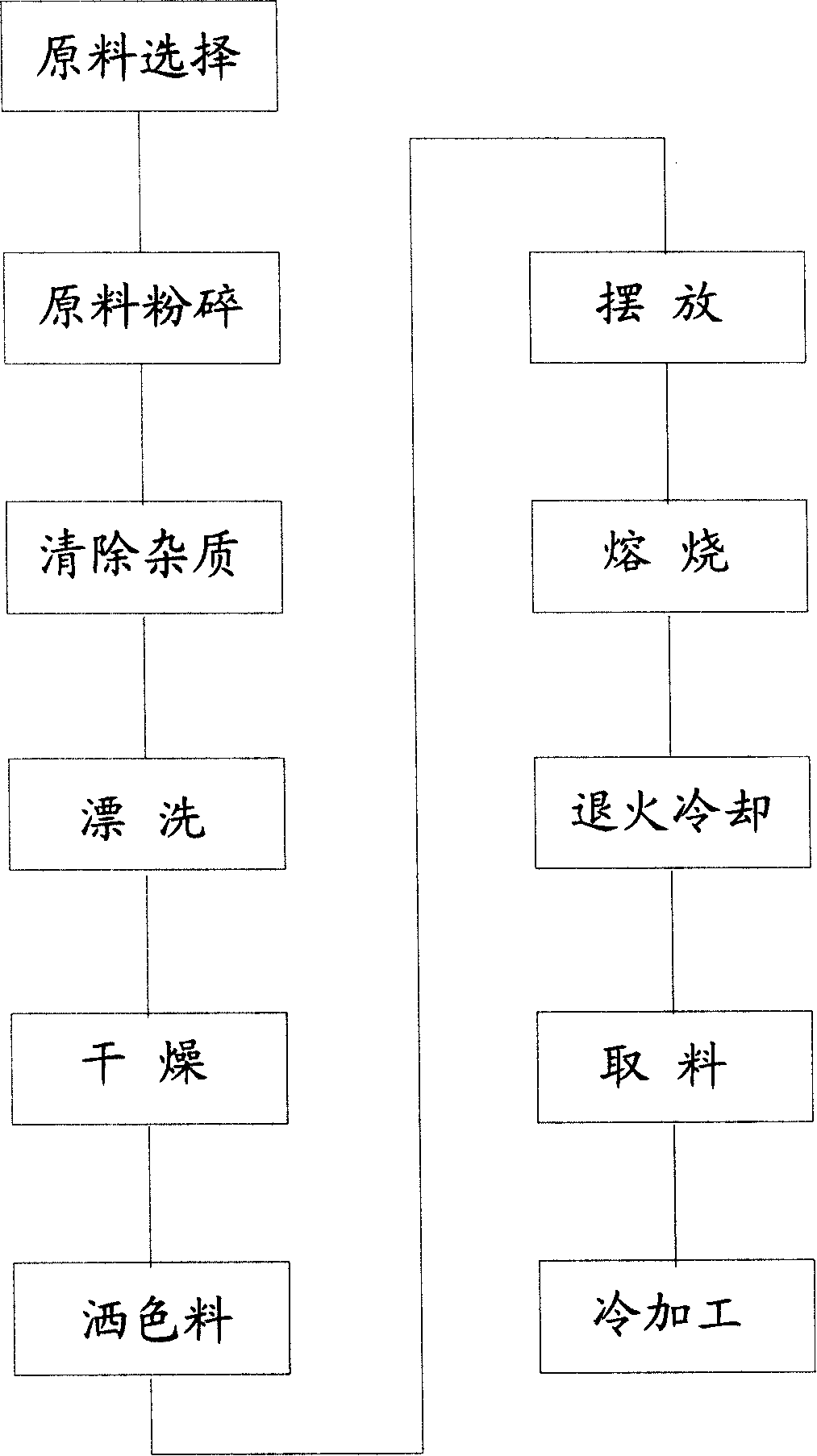

[0016] The specific implementation will be described below in conjunction with the accompanying drawings.

[0017] Such as figure 1 Shown, the preparation method of colored glaze of the present invention, comprises following processing step:

[0018] Raw material selection: select ultra-clear glass scraps or optical glass scraps available in the market;

[0019] Raw material crushing: crush ultra-white glass scraps or optical glass scraps into irregular blocks with a diameter of 40mm-80mm;

[0020] Use 5%-15% acid solution (HCL, H2SO4 or HNO3) to remove raw material impurities, mainly to oxidize and remove the metal component iron in the raw material;

[0021] Rinse with pure water and dry for later use;

[0022] Sprinkle one or two sides of the washed and dried glass raw material with high-temperature pigment, that is, glaze;

[0023] Then place the glass block flat on the glass melting furnace, place the glass block at a thickness of 1mm per square meter, and place the g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com