Assembly building method for energy-saving reconstruction of existing building

A technology for energy-saving renovation and existing buildings, which is applied in building structure, construction, building maintenance, etc. It can solve the problems of failing to meet energy consumption indicators, achieve the effects of easy production and construction, enhanced earthquake resistance, and improved overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

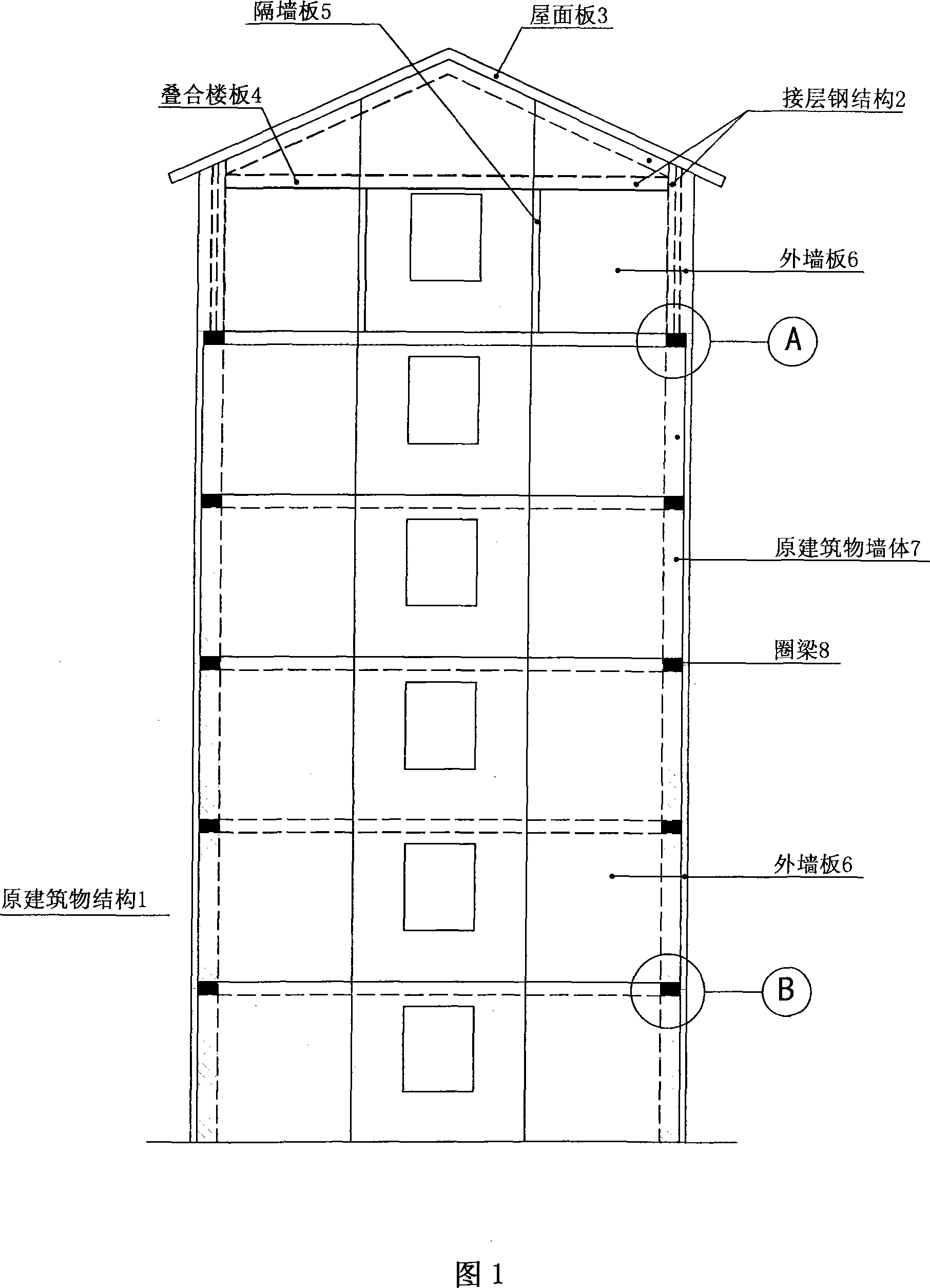

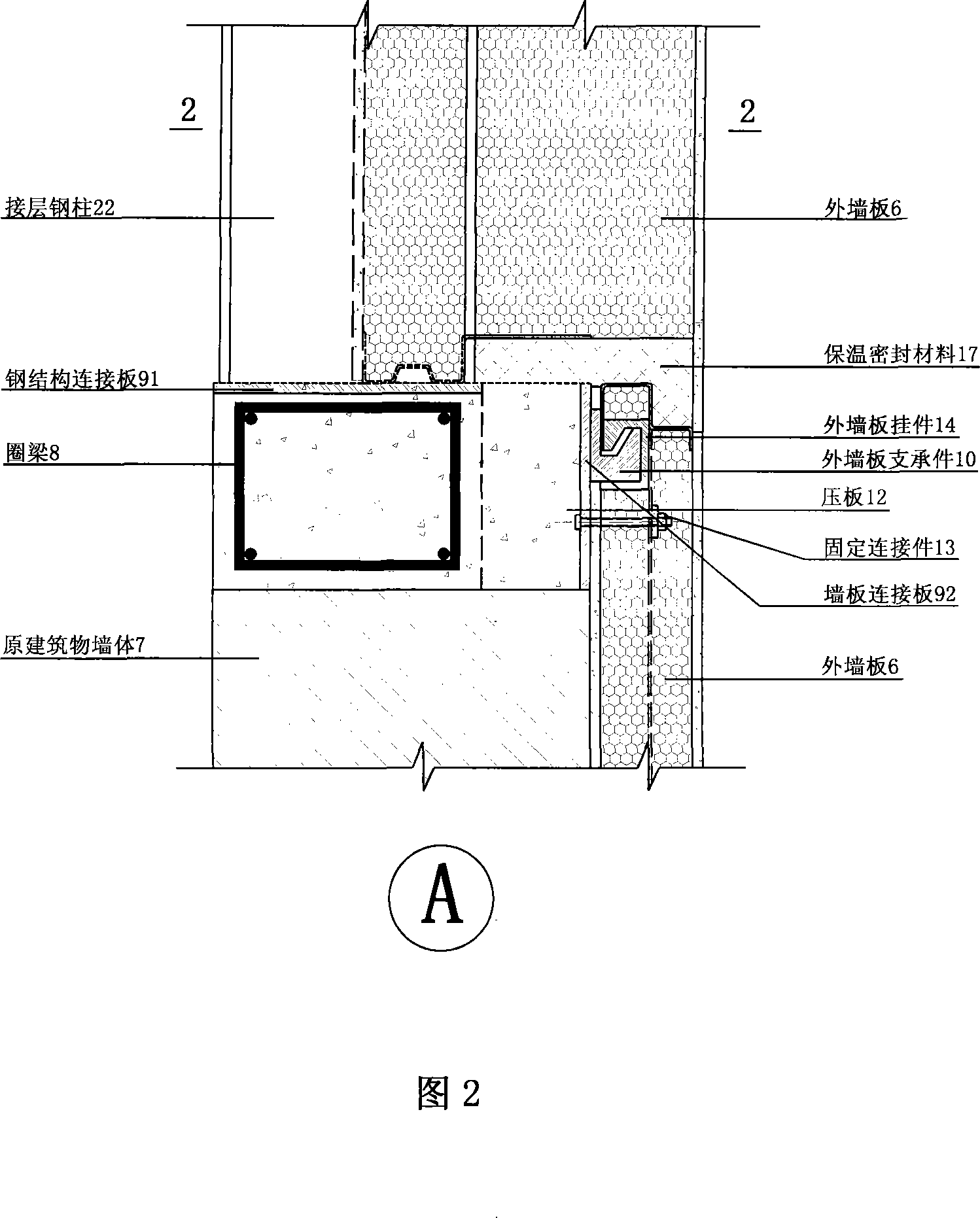

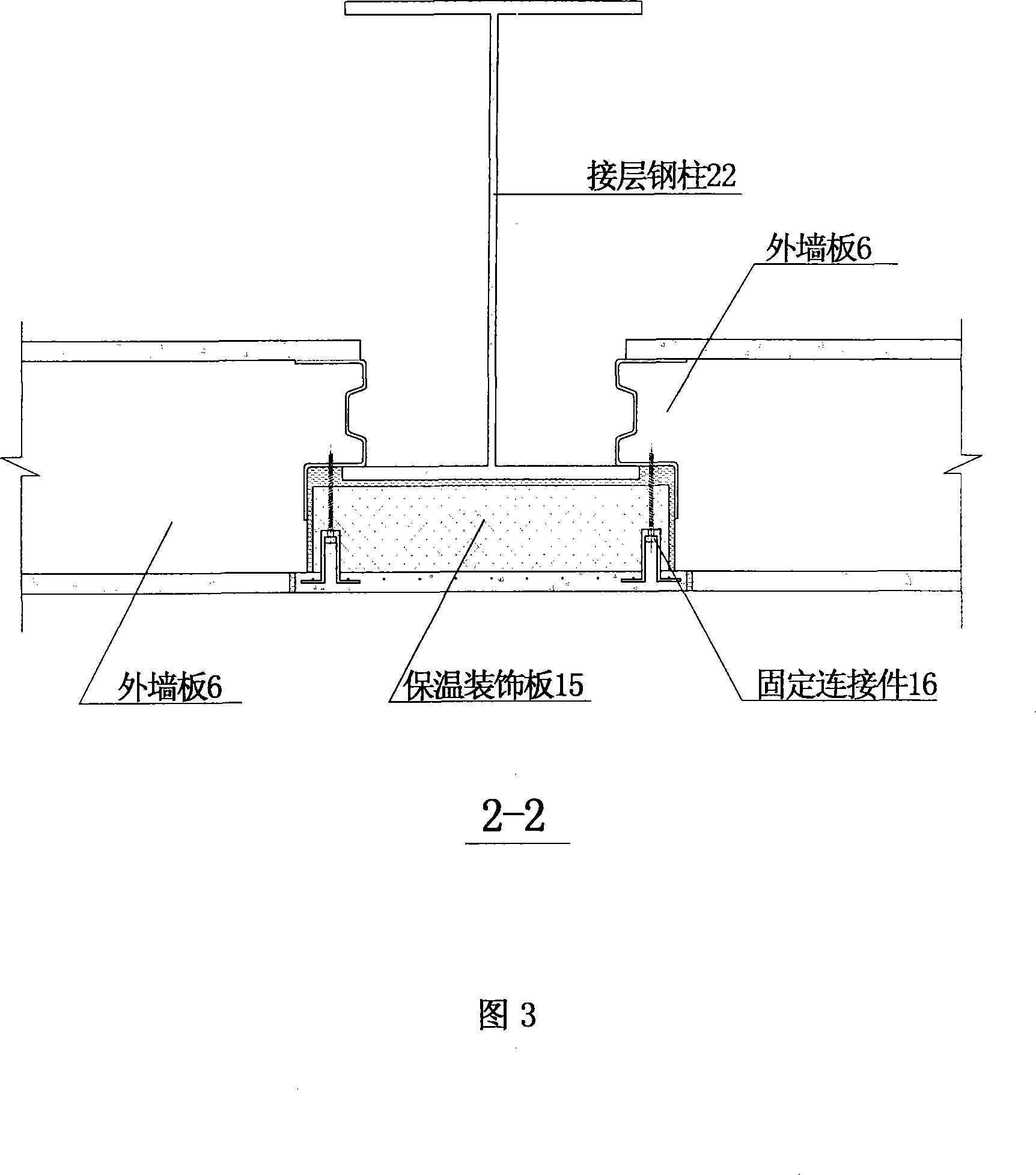

[0056] As shown in Figures 1 and 2, the prefabricated construction method of adding additional floors to existing buildings and simultaneously completing energy-saving renovations of the present invention includes: adding a steel structure connecting plate 91 on the top of the original building structure 1; Structure 2, and it is fixed with the steel structure connecting plate 91 to realize the connection with the original building structure; the energy-saving composite exterior wall panel 6 with foamed cement material, the partition wall panel 5, the laminated floor slab 4 and the foamed cement material The energy-saving composite roof panel 3 of the material is assembled and connected with the laminated steel structure 2 directly through the panel connectors or directly on site, and the gap between the inside and outside of the panel and between the panel and the original building structure is filled with thermal insulation and sealing materials, and the original structure is ...

Embodiment 2

[0069] The prefabricated construction method for converting existing buildings from flat to slope and simultaneously completing energy-saving transformation of the present invention includes: adding a steel structure connection plate 91 on the top of the original building structure 1, setting a steel frame for roof flat to slope, and connecting with the steel structure The board 91 is fixed to realize the connection with the original building structure; the energy-saving composite roof panel 3 with foamed cement material is set, connected with the steel frame through the board connector or directly, and between the inside and outside of the board, and between the board and the original building structure The gaps are filled with thermal insulation and sealing materials, which completes the transformation of the original building's roof for energy saving and flat-to-slope conversion. Add a wall panel connecting plate 92 and an exterior wall panel support 10 on the outside of the...

Embodiment 3

[0071] The prefabricated construction method of adding additional floors to an existing building and completing energy-saving renovation at the same time of the present invention includes: adding a wall board connecting plate 92 on the top of the original building structure, and setting an energy-saving composite exterior with foamed cement material on it Wall panels 6, partition wall panels 5, laminated floor slabs 4 and energy-saving composite roof panels 3 with foamed cement materials, and the composite exterior wall panels 6, partition wall panels 5 and wall panel connecting plates 92 are fixed to realize the integration with the original Building structure connection; connecting and fixing composite exterior wall panels 6, partition wall panels 5, laminated floor slabs 4, and energy-saving composite roof panels 3 with foamed cement materials, so as to realize unstructured prefabricated upper floors; The gap between the inside and outside, the board and the original buildin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com