Layered quantitative gas filling device

A technology of steam injection and sub-injection valve, which is applied in the fields of production fluids, wellbore/well components, earth-moving drilling, etc., can solve the problems of oil well casing damage, unreasonable structure, lack of protection devices, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

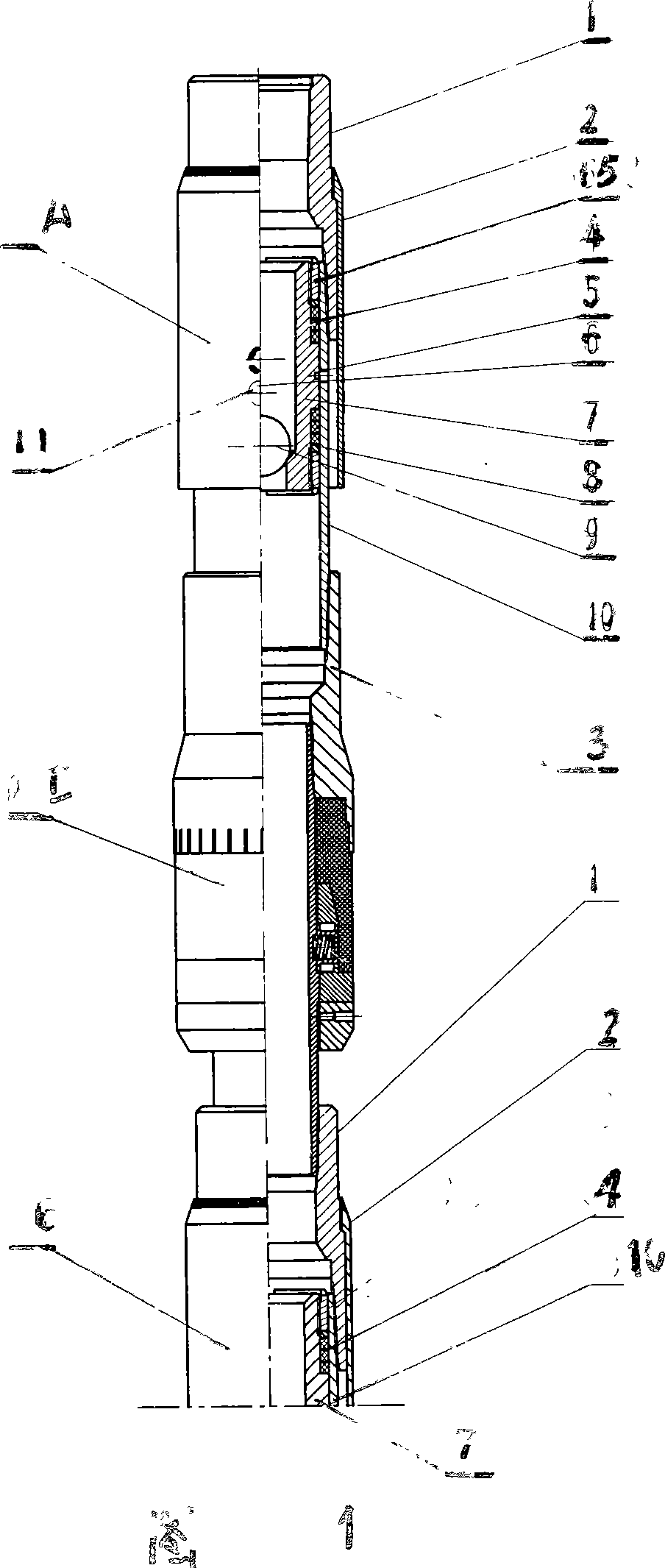

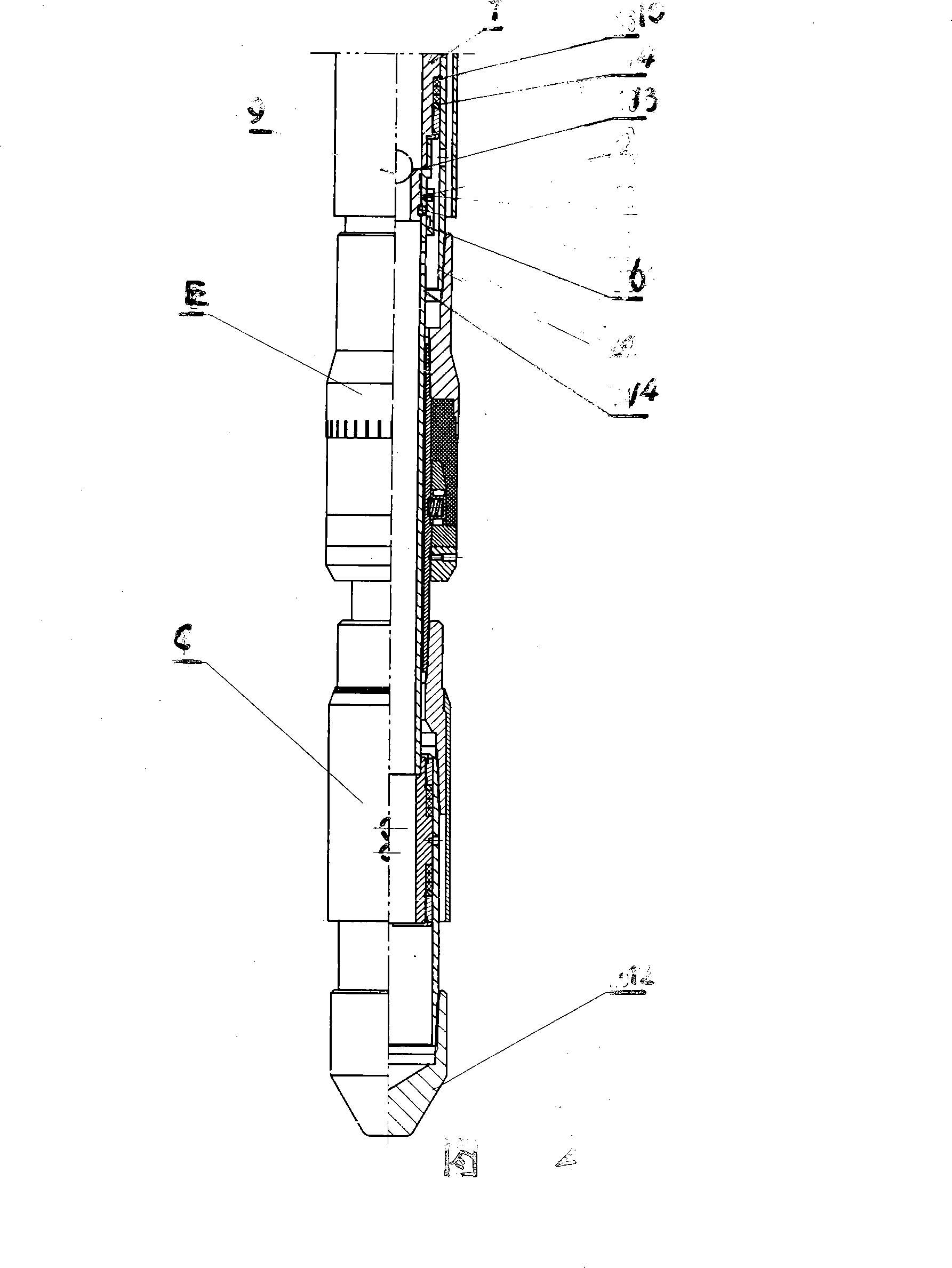

[0014] In Figures 1 and 2, the layered and quantitative steam injection device is connected between the lower end of the outer pipe 10 in the first-stage split injection valve A and the upward steam packer D through a variable diameter joint 3, and the upper steam seal The second-stage dispensing valve B and the third-stage dispensing valve C connected under the spacer are connected to the lower-injection steam packer E through the screw thread of the upper joint 1 and the reversing pipe.

[0015] The one-, two-, and three-stage dispensing valves are equipped with a pressure ring 15 and a graphite ring 4 on the upper joint 1 to seal the gap between the inner and outer tubes 10 and the inner tube 7 of the upper joint, and the inner tube 7 is installed inside the outer tube 10 , are fixed with shear pins 5 between each other, because there are air outlet holes 6 drilled on the inner pipe wall, and four air outlet holes are drilled on the outer pipe wall, so that when the steel ba...

Embodiment 2

[0018] When working, the upper joint 1 of the present invention is connected with the steam injection pipeline, and the lower end of the first-stage injection valve A is sequentially connected with the upper-injection steam packer D, the second-level injection valve B, and the lower-injection steam packer E , Three-stage separate injection valve C Finally screw the plug under the three-stage separate injection valve, that is, the assembly is completed. After the device goes down the well and enters the oil layer, it starts to inject high-temperature steam into the inner pipe 7 to seal the upper injection steam. The device D and the steam injection packer E are seated on the casing wall of the oil well, and then the steel ball 9 is put into the pipe string from the wellhead to press the upper and lower steam packers D and E. At this time, the shear The cutting pin 5 breaks, and the inner pipe 7 moves downward, so that the steam flows from the air outlet hole 6 of the inner pipe ...

Embodiment 3

[0019] Embodiment 3, the upward steam injection packer D and the downward steam injection packer E described in the present invention are thermal recovery steam injection packers in the prior art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com