Control valve type lead accumulator

A lead-acid battery and control valve technology, used in lead-acid batteries, electric vehicles, final product manufacturing, etc., can solve problems such as unusable machines, and achieve the effect of suppressing short circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] The following is a survey of the number of cycle life and the occurrence of short circuits for each test body of the valve-controlled lead-acid storage battery with various components of the negative electrode active material, the distance between the positive electrode plate and the negative electrode plate, and the reaction utilization rate of the negative electrode active material. , the test results are described as examples. The experimental bodies prepared here are all controlled lead storage batteries with a capacity of 12Ah and an electromotive force of 6V.

[0031]

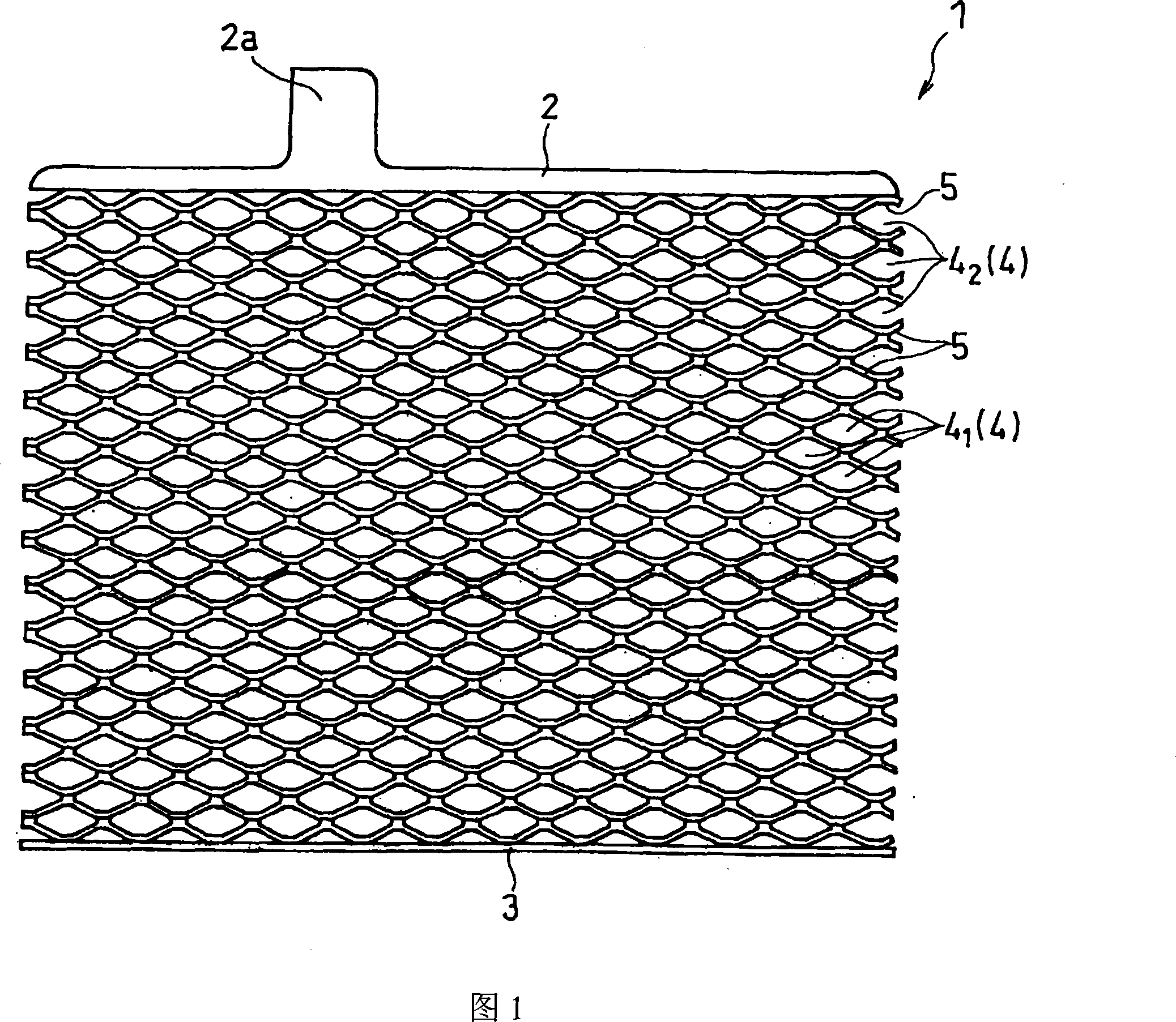

[0032]Ball mill (ball mill) lead powder (lead oxide with a degree of oxidation of 70%) is added with 10kg of water and 5kg of dilute sulfuric acid (density 1.300g / cm2 at 20°C) per 100g of lead powder. 3 ) for mixing to make negative electrode active material slurry (referred to as slurry PA). After the slurry PA is filled into each mesh 4 of the mesh metal grid 1 shown in FIG. 1 , it is aged and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com