Soyabean protein meat and preparing technique thereof

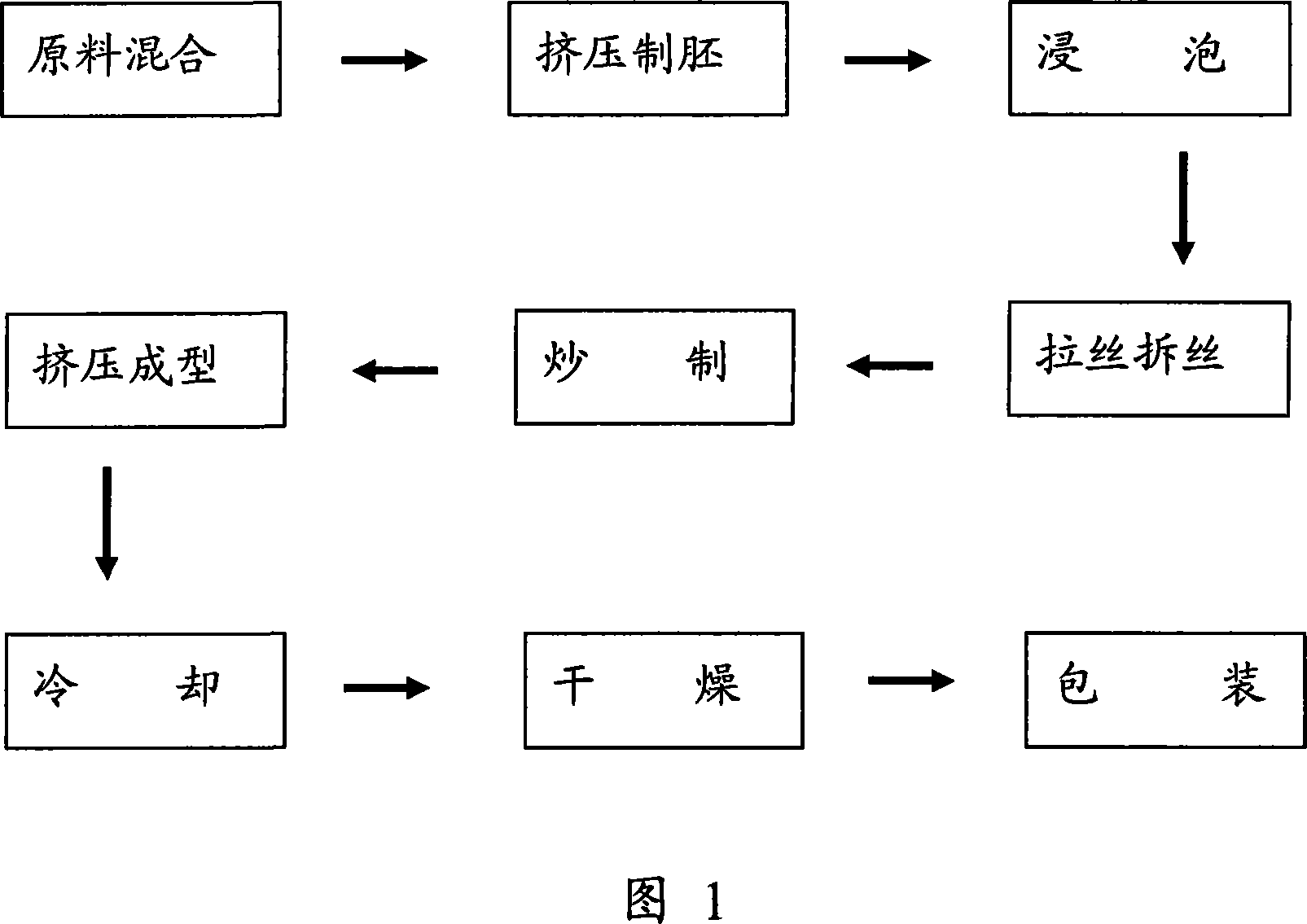

A technology for soybean protein meat and production process, applied in the field of soybean protein meat and its production process, can solve the problems of irregular shape of soybean protein meat, oily product surface, inconvenient eating, etc., and achieves regular shape, uniform taste and distribution. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Mix 4 kg of crushed soybean protein powder, 1 kg of gluten powder and 1.25 kg of water, stir evenly, then send the mixed material into an extrusion molding machine, and extrude at 210°C to obtain embryos material;

[0041] (2) Soak the prepared blank in drinking water for 30 minutes, dehydrate after drawing and dismantling, add 0.048 kg of starch and 4.752 kg of seasoning (0.15 kg of edible salt and 0.5 kg of sucrose) to the filamentous blank. kg, 0.782 kg of glucose, 1 kg of beef powder, 0.1 kg of monosodium glutamate, 1 kg of rice wine, 1.2 kg of oil and ester, 0.02 kg of food flavor), 0.0035 kg of potassium sorbate and 0.7868 kg of water, stir well and stir fry for 25 minutes. The frying temperature is 200°C;

[0042] (3) Add 0.183 kg of uniformly mixed starch, 5.917 kg of seasoning (including 2.1 kg of sucrose, 1.7 kg of glucose, 0.5 kg of beef powder, 1.5 kg of five-spice powder, and 0.117 kg of monosodium glutamate), sodium diacetate 0.0035 kg, stir evenly, ...

Embodiment 2

[0044] (1) Mix 4.75 kg of soybean protein powder, 0.25 kg of gluten powder and 1.2 kg of water after crushing, stir evenly, then send the mixed material into an extrusion molding machine, and extrude at 180° C. to obtain a blank;

[0045] (2) Get the prepared blank and soak it in drinking water for 200 minutes, dehydrate after being decomposed into filaments, add 0.05 kg of starch and 0.6 kg of seasoning (wherein 0.2 kg of edible salt, 0.15 kg of sucrose, 0.05 kg of pork powder, 0.05 kg of monosodium glutamate, 0.08 kg of rice wine, 0.05 kg of oil, 0.02 kg of food flavor). 0.0015 kg of preservative potassium sorbate and 2 kg of water, stir evenly and fry in a wok for 180 minutes at 50°C;

[0046] (3) Add 0.3 kg of uniformly mixed starch, 0.3 kg of seasoning (including 0.05 kg of glucose, 0.06 kg of pork powder, 0.15 kg of curry powder, and 0.04 kg of monosodium glutamate), and 0.0015 kg of preservative sodium diacetate , send the mixed material into an extruder, extrude at 10...

Embodiment 3

[0048] (1) Mix 4 kg of soybean protein powder, 1 kg of gluten powder, and 1.2 kg of water after crushing, stir evenly, then send the mixed material into an extrusion molding machine, and extrude at 120° C. to obtain a blank;

[0049] (2) Get the prepared blank and soak in drinking water for 50 minutes, dehydrate after being decomposed into filaments, add 0.006 kilograms of starch and 0.594 kilograms of seasonings (wherein edible salt 0.18 kilograms, 0.15 kg of sucrose, 0.014 kg of fennel, 0.005 kg of cinnamon, 0.005 kg of clove, 0.01 kg of pepper, 0.01 kg of licorice, 0.05 kg of chicken powder, 0.05 kg of monosodium glutamate, 0.1 kg of rice wine, 0.02 kg of food flavor), 0.0015 kg of potassium sorbate and 1.2 kg of water, stir well, put into the pot and fry for 120 minutes, the frying temperature is 90°C;

[0050] (3) Add 0.15 kg of uniformly mixed starch and 0.475 kg of seasoning (including 0.27 kg of sucrose, 0.06 kg of chicken powder, 0.025 kg of chili powder, 0.015 kg of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com