Simple spray coating assembly line

A production line, simple technology, applied in the direction of coating, spraying device, device for coating liquid on the surface, etc., can solve the problems of supply capacity, output or quality dependence, restricting the development of enterprises, etc., to achieve good health, economical Energy, compact and flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

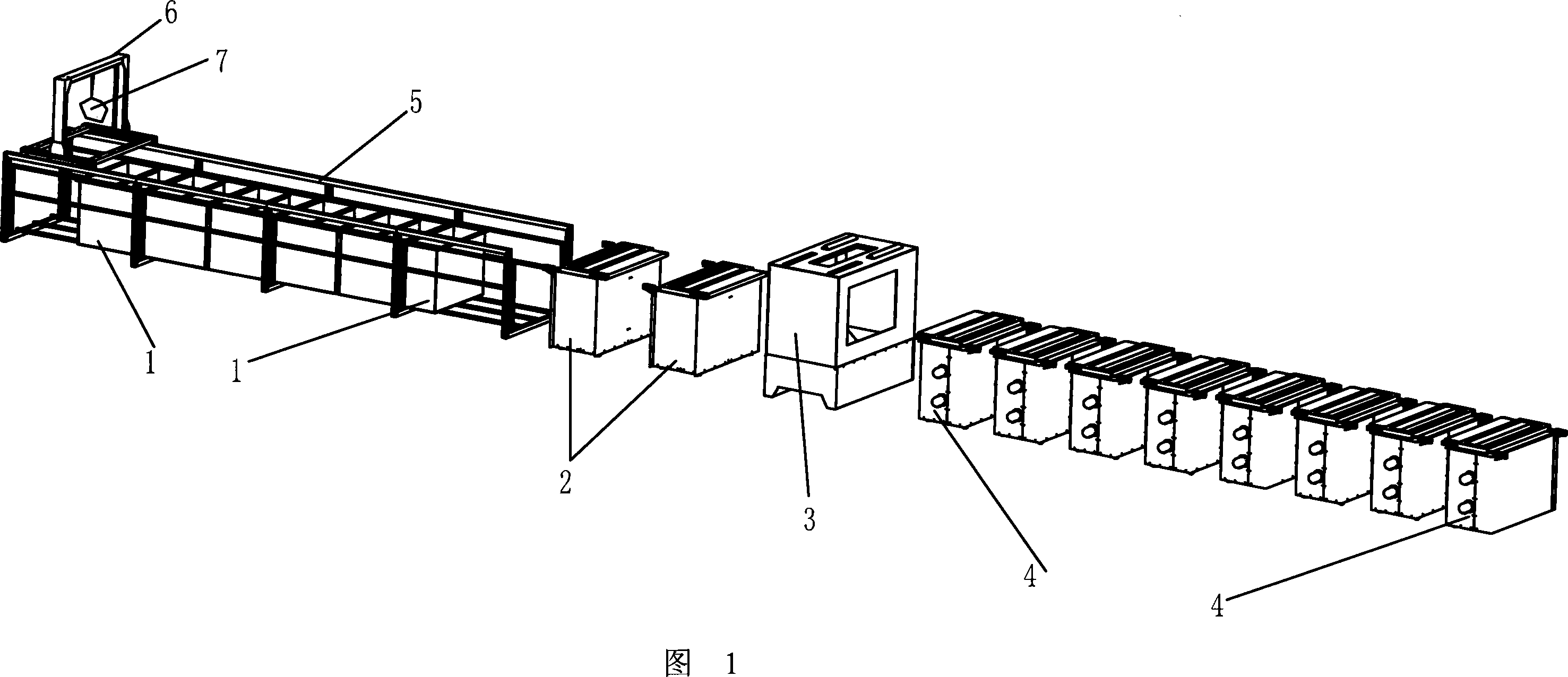

[0015] Embodiment: As shown in Figure 1, a simple spraying production line is characterized in that: the production line includes a pretreatment area 1, a drying area 2, a spraying area 3 and a curing area 4 distributed sequentially from front to back, and the front The processing area 1, the drying area 2, the spraying area 3 and the curing area 4 are sequentially fixed on the production line frame 5, and the production line frame 5 is also provided with a sliding crane 6 which slides and cooperates with the guide rail on the production line frame 5, and the sliding The crane 6 is provided with a workpiece clamping device; the production line also includes an electrical control device for joint control and management of each area and the sliding crane 6 .

[0016] A glass protective cover can also be set outside the production line.

[0017] The production line frame 5 is constructed of linear available profiles, and each functional area is uniformly integrated on the frame c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com