Method for separating N-ethylpiperazine-ethanolamine azeotropic mixture by azeotropic rectifying intermittent operation

A technology of azeotropic mixture and ethylpiperazine, which is applied in the field of separation of N-ethylpiperazine-ethanolamine, can solve problems that have not been seen yet, and achieve the effect of less equipment investment and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

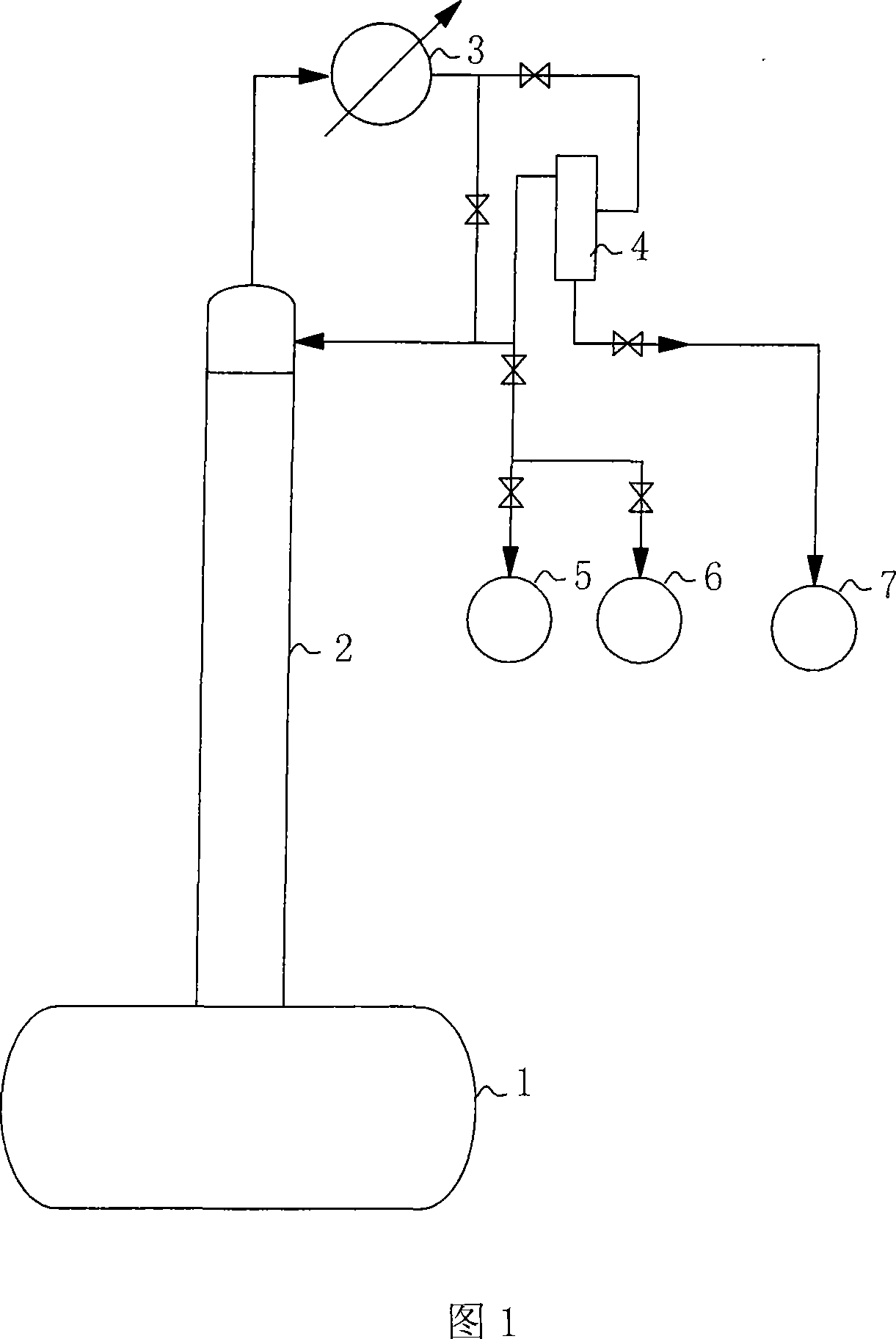

Image

Examples

Embodiment 1

[0010] The intermittent azeotropic distillation device is adopted, the diameter of the azeotropic distillation column is φ25mm, and the internal packing of φ2.5×2.5θ mesh ring is installed, and the height of the packing layer is 1.1m. Put 500ml of N-ethylpiperazine-ethanolamine mixture (wherein N-ethylpiperazine 88%, 12%, both are mass percentages) in heating kettle, then add cyclohexane 250ml. Turn on the heat source of the heating kettle and the cold source of the condenser, and the azeotropic distillation column starts to operate, and the liquid condensed by the condenser connected to the azeotropic distillation column enters the phase separator for phase separation, the light phase is refluxed, and the heavy phase is extracted; when the phase is separated When the liquid in the device is basically not separated into phases, the phase separator is isolated, and part of the condensed liquid is directly refluxed into the azeotropic distillation column, and part of it is extrac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com