Industry ray detection negative film digitalizer

A radiation detection and industrial technology, applied in X-ray equipment, material analysis using radiation, television, etc., can solve problems such as inability to share, no unified standard, and large number of film storage, and achieve the effect of image distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings.

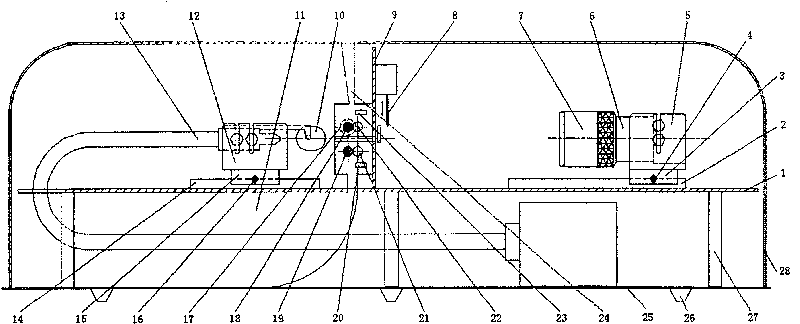

[0017] refer to figure 1 , the present invention includes an upper substrate 1 for fixing an image acquisition device, a strip-shaped optical fiber cold light source, a film feeding device and a shading device, the right half of the upper substrate 1 is installed with a slide rail 2, and the ball slider 3 is installed on the slide rail 2 It is also equipped with fastening screws 4, the linear array CCD6 is installed on the camera height adjustment device 5 connected with the ball slider 3, the close-up lens 7 is installed on the linear array CCD6; The shading device 8 composed of iron and shading plate is installed on the right side of the vertical plate 9, and the film feeding device is installed on the left side of the vertical plate 9, including: a circular grating sensor 17 installed on the upper driving roller shaft 18, a lower driving roller Shaft 19, photoele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com