Method for realizing retroact movement control in numerically controlled machine system

A technology of motion control and CNC machine tools, applied in the direction of digital control, electrical program control, etc., can solve the problems of uneconomical re-cutting, vulnerable nozzles, etc., and achieve the effect of simple and convenient realization process, wide application range, fast and efficient operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

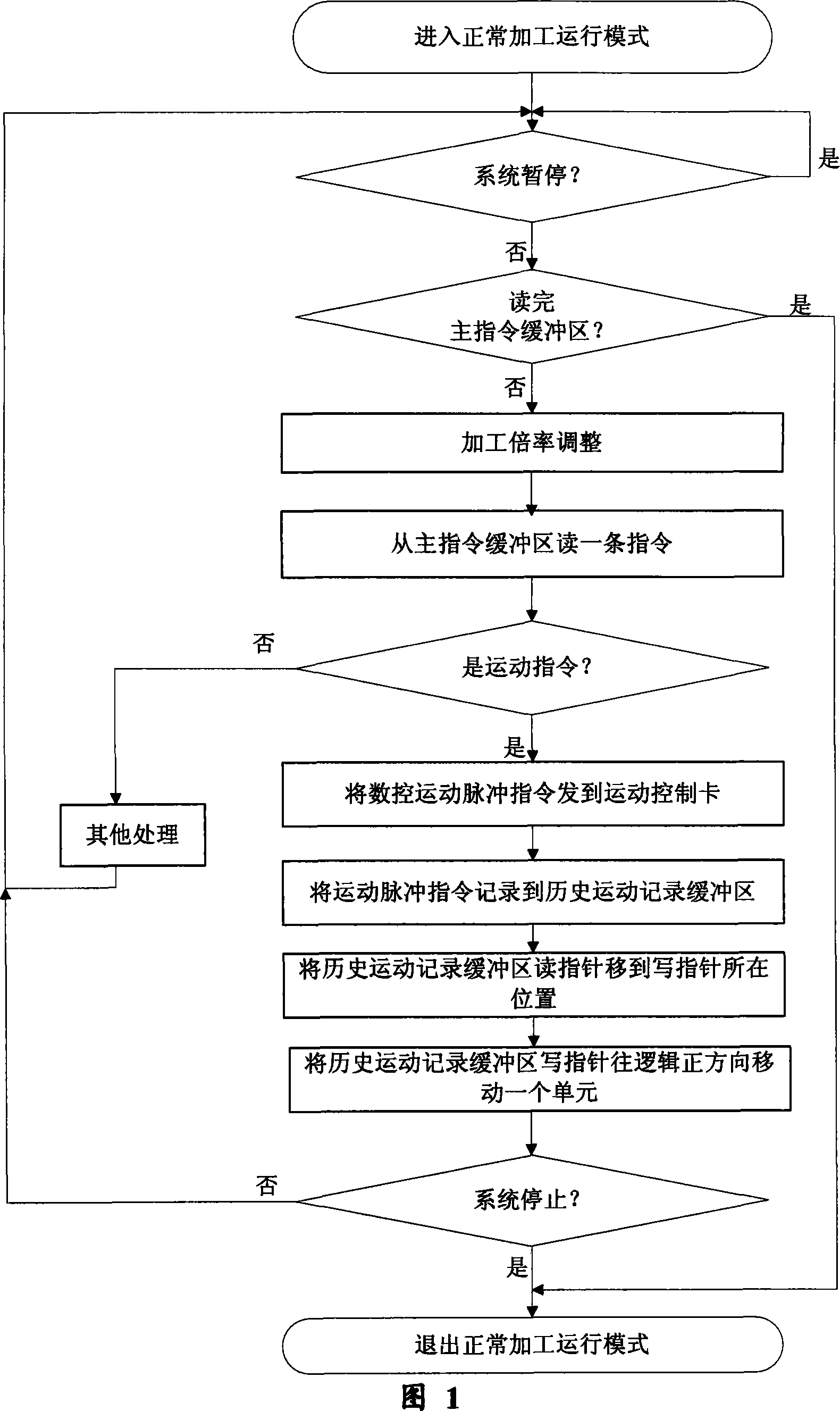

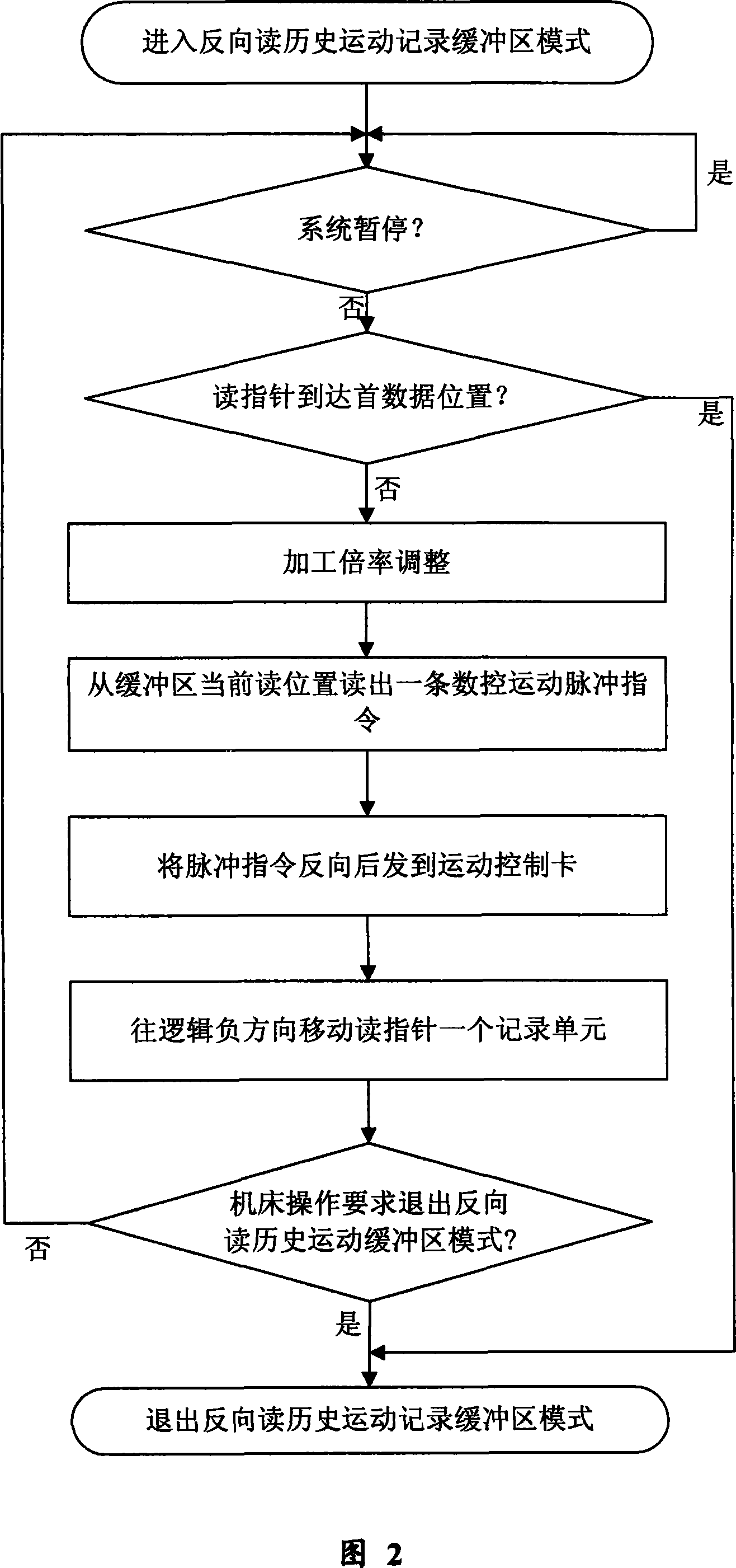

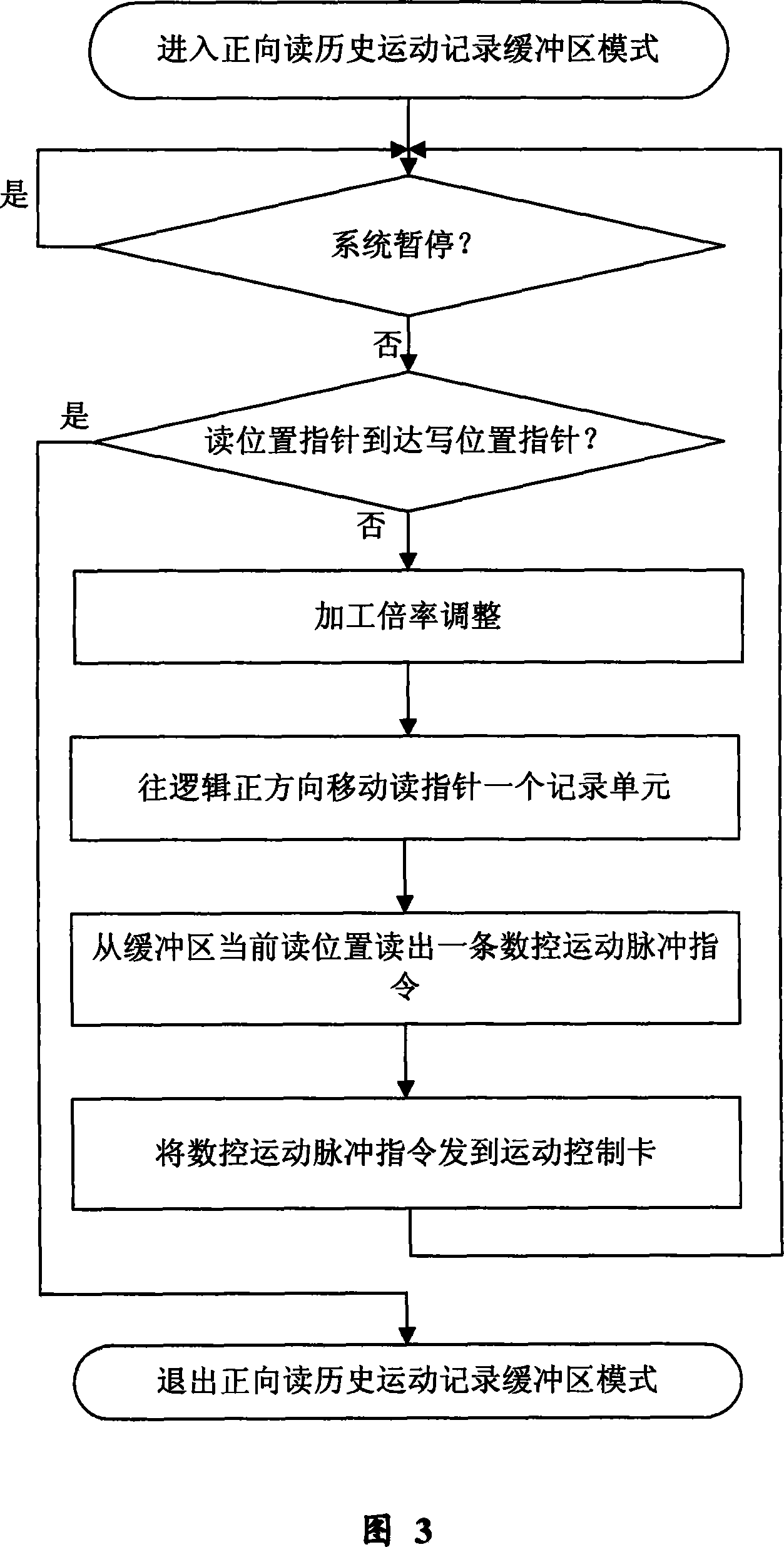

[0056]In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

[0057] First, explain several terms in the technical field of CNC machine tools:

[0058] Breakpoint resume - a function of CNC control software, execute this function, and the system will continue to execute from the last processing interruption.

[0059] Numerical control motion pulse command—the motion command pulse information sent by the numerical control software to the motion control card, including axis information, the number of pulses of each single axis and the direction of motion, wherein the direction of motion is represented by a plus or minus sign. In the method of the present invention, it is required The memory size it occupies remains unchanged.

[0060] Processing ratio—the ratio of the current processing speed to the normal processing speed, called the processing ratio.

[0061] Handwheel - the abbreviation of hand pulse ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com