High voltage resistant over-current protective element

A technology for protecting components and overcurrent, applied to resistors with positive temperature coefficients, etc., can solve the problems of reduced yield, low energy, difficult process control, etc., and achieve the effect of increasing production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

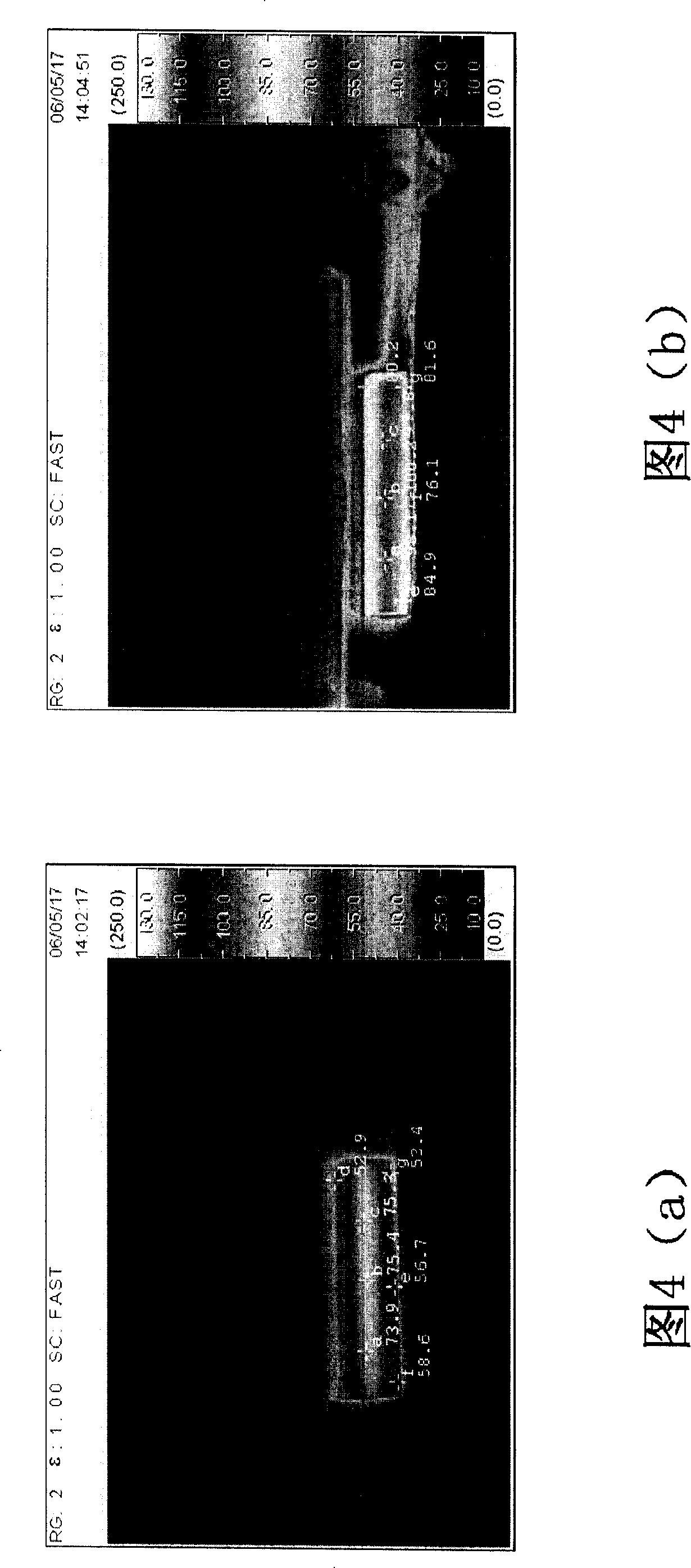

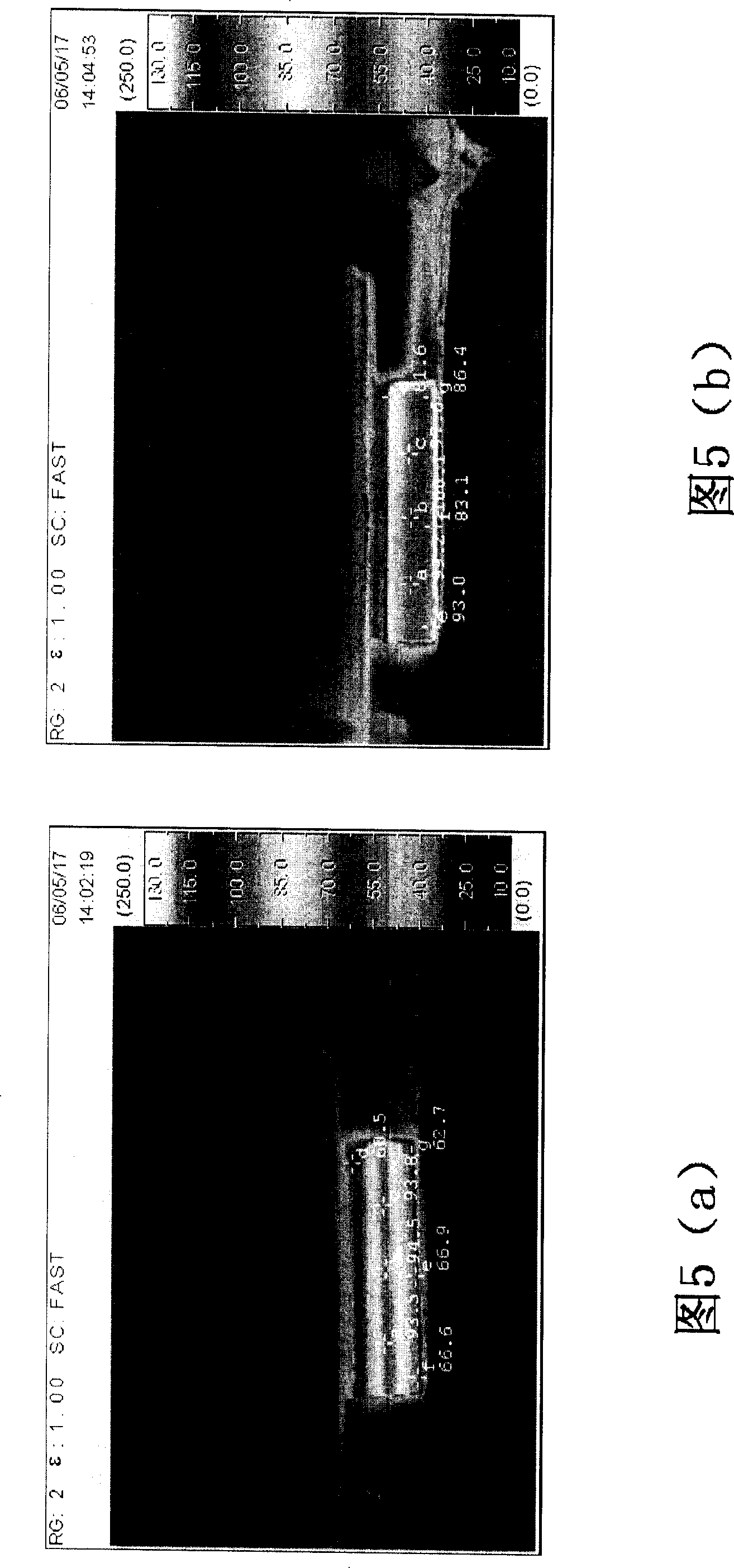

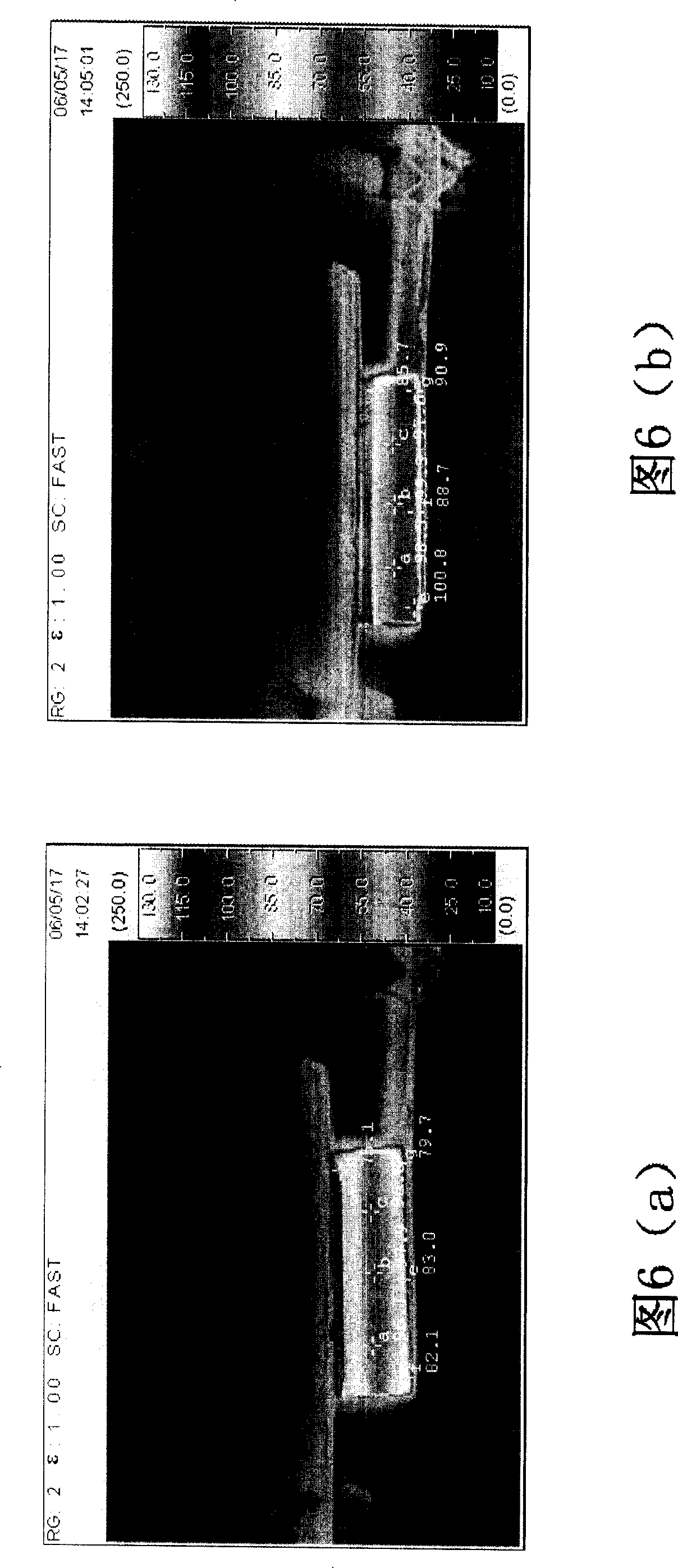

[0017] An embodiment of the high voltage overcurrent protection device and its manufacturing method of the present invention will be described below with reference to the accompanying drawings.

[0018] Regarding the production method, first set the feed temperature of the batch mixer (Hakke-600) at 160° C., and add the premix (the premix is placed in a steel cup and stirred evenly with a measuring spoon). The rotational speed of the mixer rotation was 40 rpm. After 3 minutes, the rotating speed was increased to 70 rpm, and the kneading was continued for 12 minutes before feeding to form a conductive composite material with positive temperature coefficient characteristics. Wherein the premixed material comprises first high-density polyethylene (HDPE-1), second high-density polyethylene (HDPE-2), conductive filler and thermal conductive filler. Table 1 shows the ingredients of the premix of the comparative example and each embodiment of the high voltage overcurrent protectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com