Method for producing anode of lithium ion battery

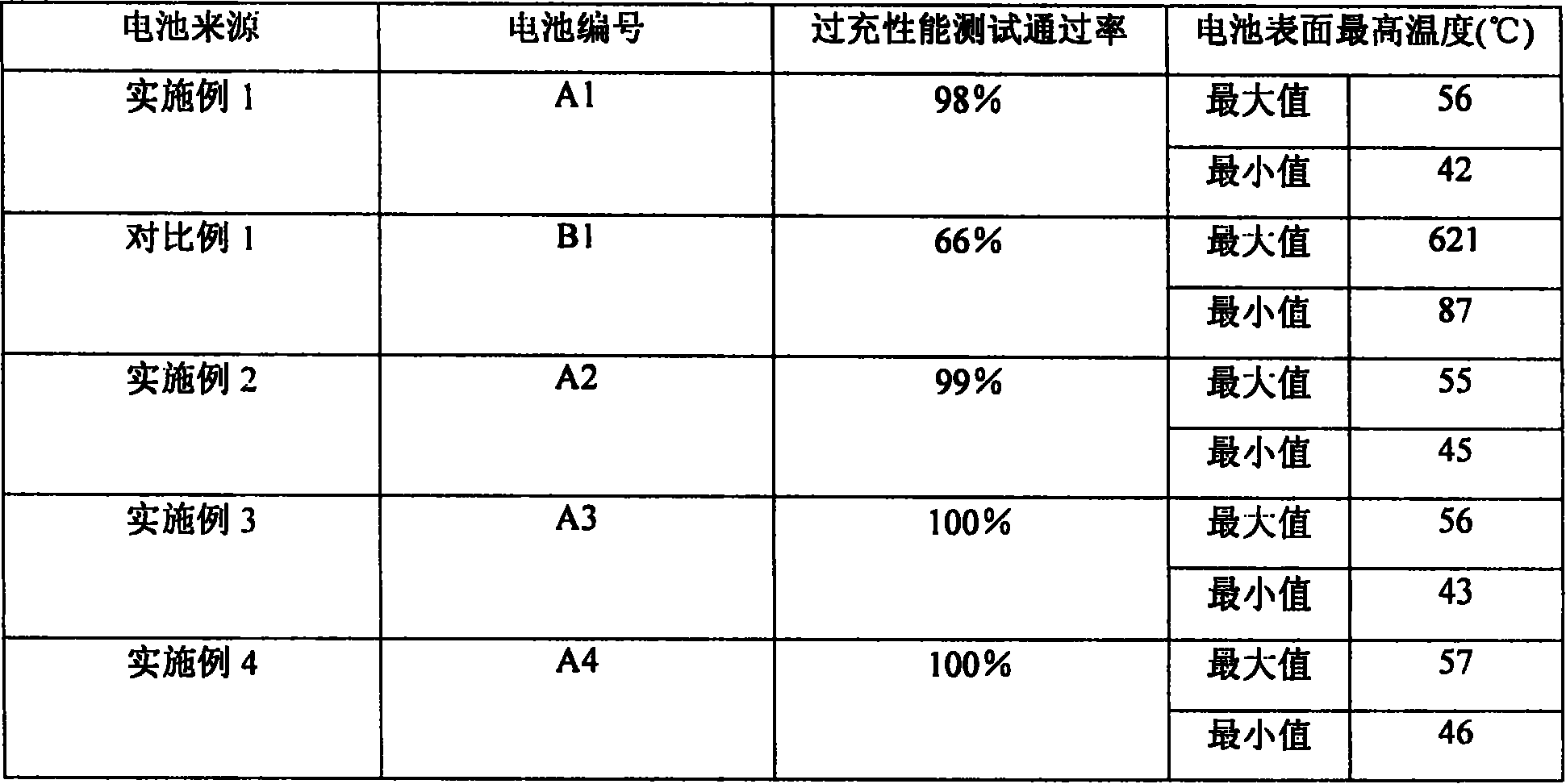

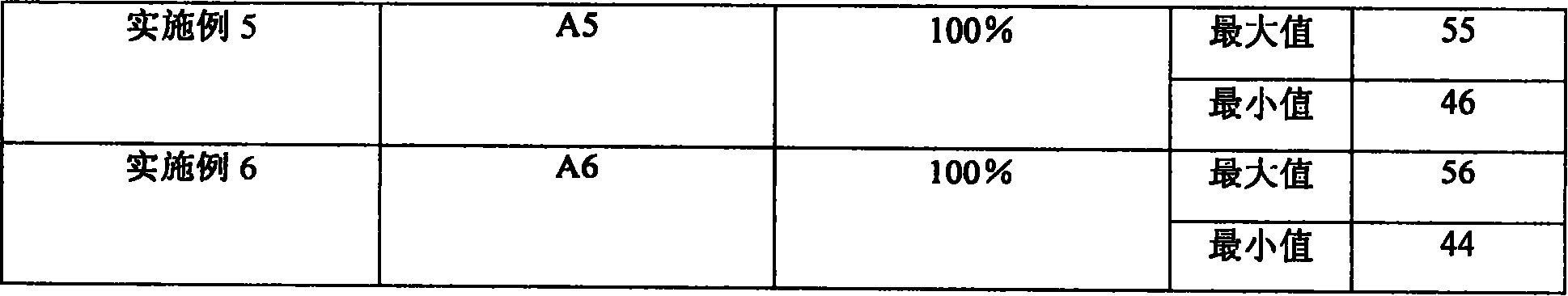

A lithium-ion battery and positive electrode technology, applied in the field of preparation of lithium-ion battery positive electrodes, can solve the problems of low pass rate of overcharge performance test and low pass rate of batteries, achieve improved pass rate of overcharge performance test, simple preparation process, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0011] The preparation method of the positive electrode of the lithium ion battery provided by the present invention includes coating the positive electrode slurry on the current collector, and then drying the sheet to obtain the current collector containing the positive electrode material layer, and pressing the current collector containing the positive electrode material layer into a sheet, the positive electrode The material layer contains a positive electrode active material and a binder.

[0012] According to the present invention, when the current collector containing the positive electrode material layer is pressed into a sheet, it is sufficient that the binder is in a molten state. Preferably, when the current collector containing the positive electrode material layer is pressed into a sheet, the temperature of the positive electrode material layer is 160-250°C.

[0013] According to the present invention, the tableting method is well known to those skilled in the art ...

Embodiment 1

[0028] This example is used to illustrate the preparation method of the positive electrode of the battery provided by the present invention and the lithium ion battery prepared by using the positive electrode.

[0029] (1) Preparation of positive electrode

[0030] Dissolve 30 grams of polyvinylidene fluoride (PVDF) in 450 grams of N-methylpyrrolidone (NMP) solvent to prepare a binder solution, and then mix 940 grams of LiCoO 2Add 30 grams of acetylene black powder into the above solution, stir and mix evenly to obtain a positive electrode slurry; use a pulper to evenly coat the positive electrode slurry on both sides of an aluminum foil with a thickness of 18 microns to form a coating with a thickness of 0.18 mm. cloth layer, then place the positive electrode in an oven and bake at 100°C for 5 hours, and then place it in a high-temperature tablet press with a roller temperature of 185°C and a roller speed of 5 rpm (produced by BYD Co., Ltd. LB-2006R), the temperature of the ...

Embodiment 2

[0038] Prepare the positive electrode of the battery and the battery according to the method of Example 1. The difference is that the positive electrode is first placed in an oven and baked at 160°C for 10 hours, and then quickly transferred to a roller with a temperature of 160°C and a roller speed of Tablet pressing was carried out on a high-temperature tablet press machine (manufactured by BYD Co., Ltd., model LB-2006R) at 20 rpm. The temperature of the positive electrode material layer was 160° C. during tablet pressing, and cooled after tablet pressing. Finally, lithium ion battery A2 was produced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com