Refrigeration compressor

A refrigerant and compressor technology, applied in mechanical equipment, machines/engines, liquid variable capacity machinery, etc., can solve problems such as large pressure, reduce volumetric efficiency, etc., and achieve the effect of reducing suction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

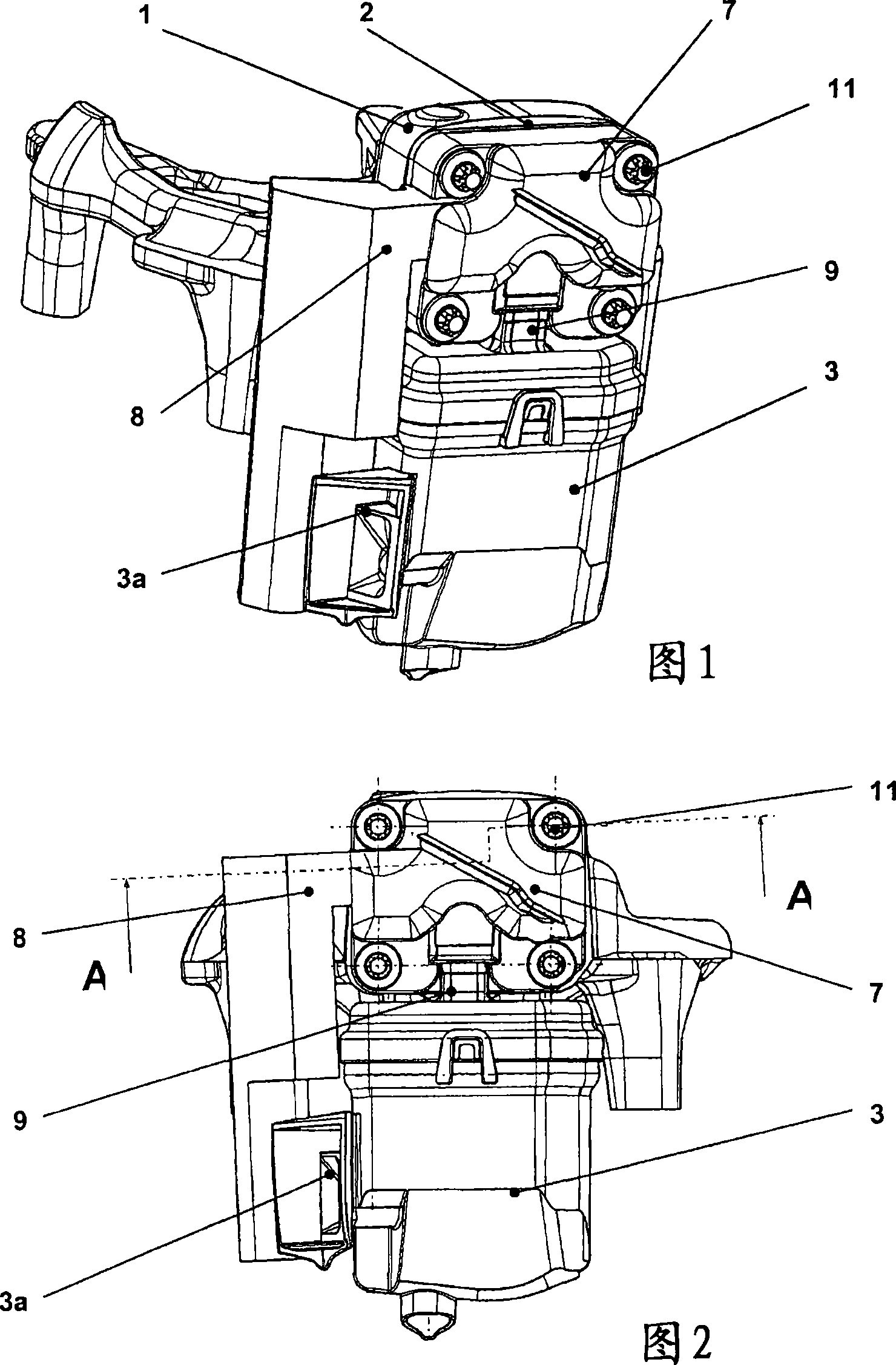

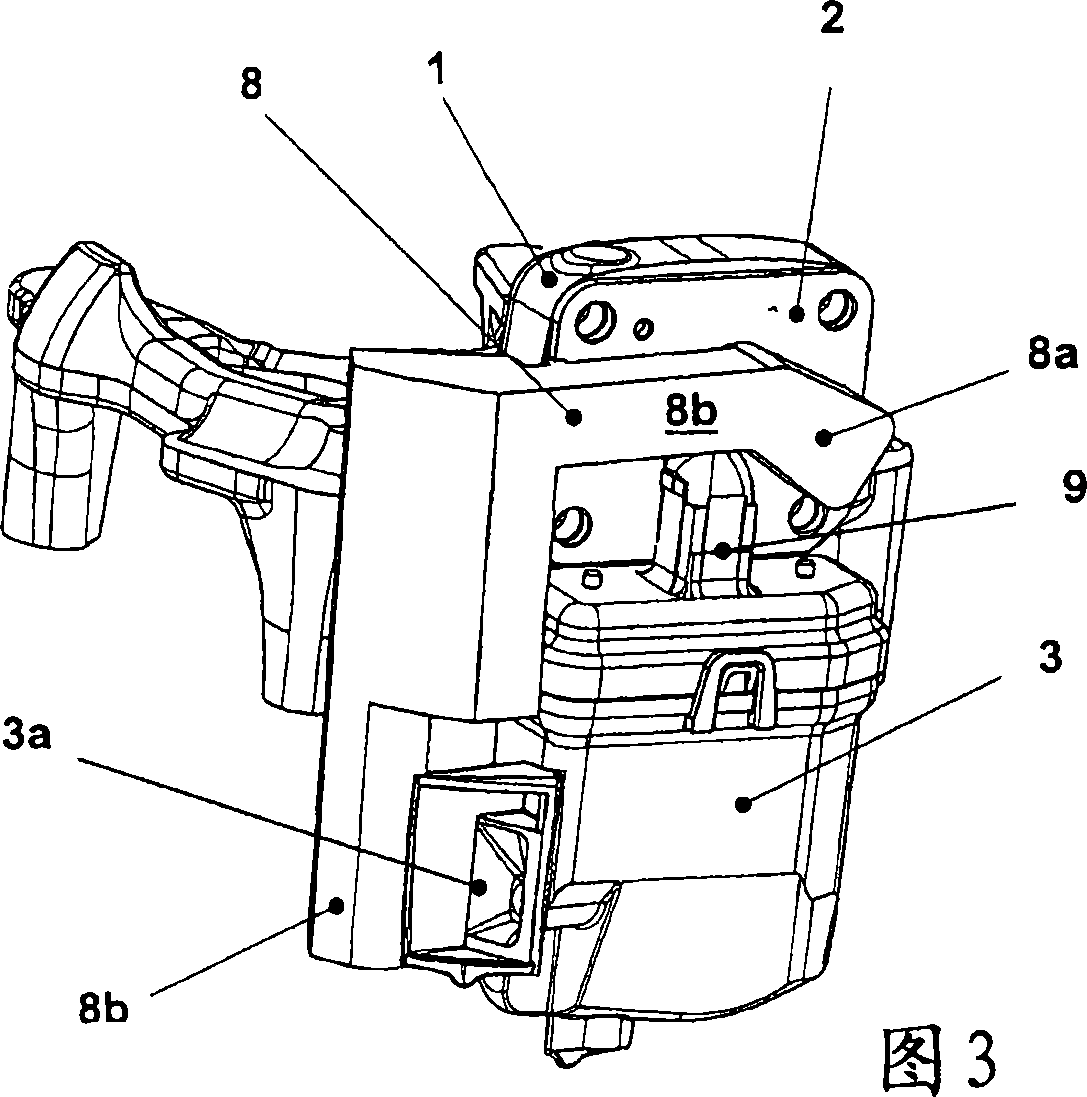

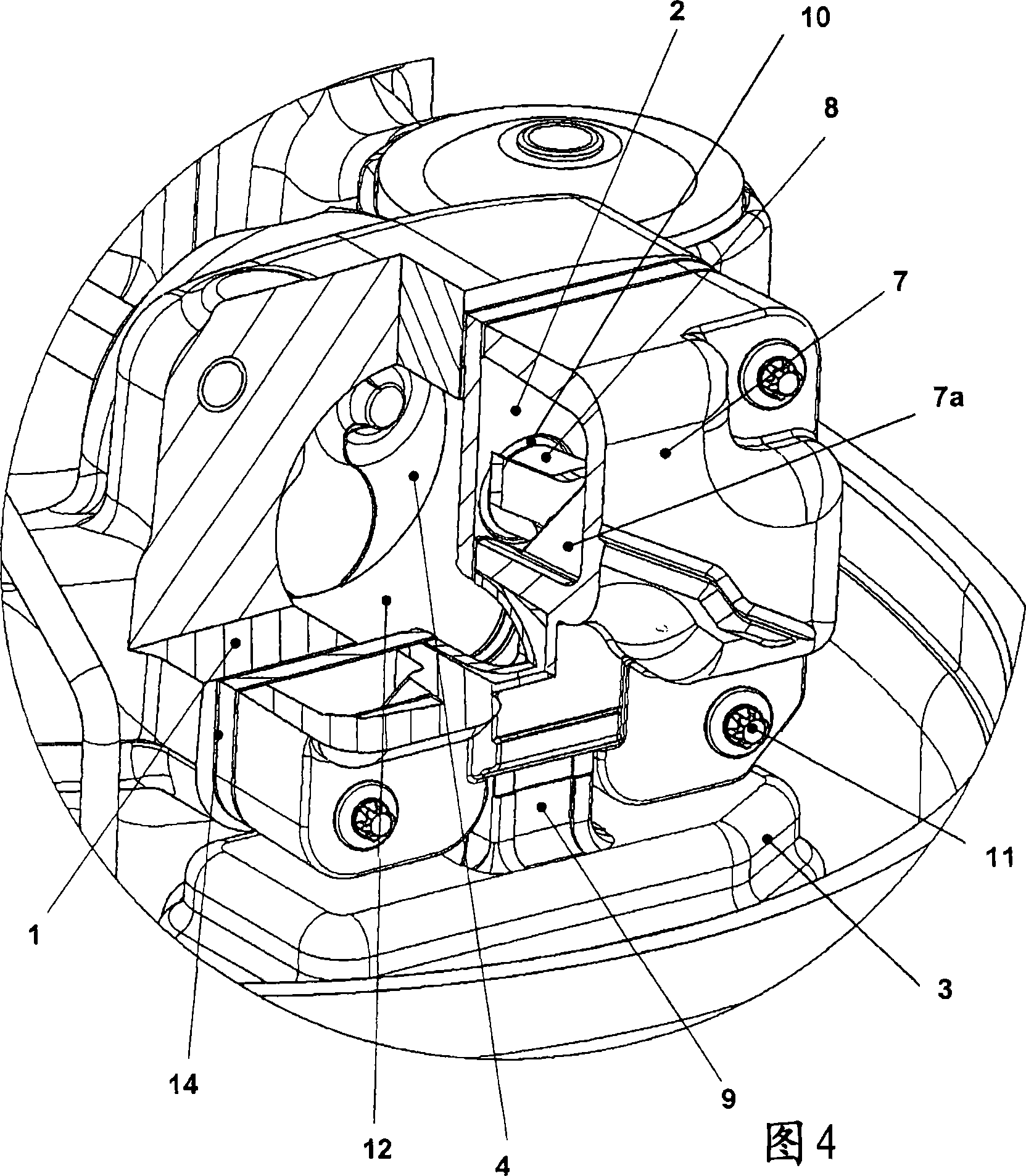

[0068] FIG. 1 shows an isometric view of a cylinder head according to the invention, in which individual parts of the cylinder block 1 , the valve plate 2 and the suction muffler 3 including the suction opening 3 a can be seen.

[0069] The basic structure of the subject hermetically sealed refrigerant compressor is known per se. The piston-cylinder-motor unit basically comprises a cylinder 1 and a piston 4 performing reciprocating motion therein, and crankshaft bearings 5 in a crankcase 5a, perpendicular to the axis 6 of the cylinder. The crankshaft bearing 5 accommodates a crankshaft (not shown) and projects into a central bore of the rotor of an electric motor (also not shown), the rotational movement of which is transmitted via a connecting rod (not shown) in a manner also known per se. to piston 4. A suction muffler 3 is located on the cylinder head itself and it serves to minimize the noise output during the intake of the refrigerant.

[0070] Figures 1 and 2 show a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com