Real-time process history server

A technology of historical record and server, applied in the direction of instrument, program control, electrical program control, etc., can solve the problems of inflexibility, inability to input experimental values, limited rewriting of historical records, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

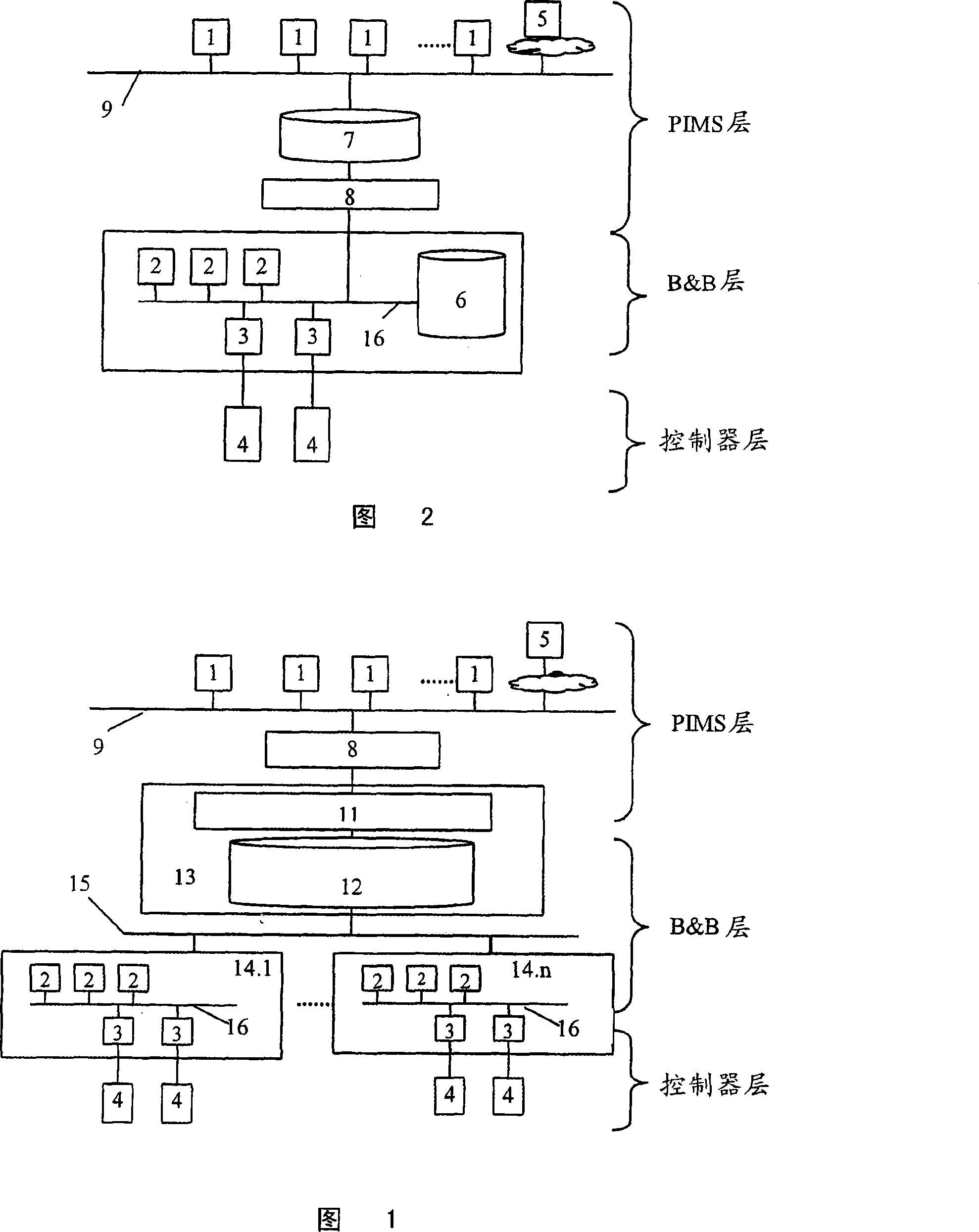

[0020] An example application of the real-time process historian server 13 according to the invention is shown in FIG. 1 . It can be seen from the figure that the real-time-process historian-server 13 can be installed close to the midpoint between the typical PIMS level and the operation and monitoring level. It can be used simply and flexibly for installations 1, 2 and 5 on two levels. Several DCS systems 14 . All mentioned data transmission systems 9 , 15 and 16 can be, for example, bus systems or redundant standard networks. The process information obtained from the technical equipment or process via the DCS systems 14.1 to 14.n or entered into the operator's workstation 2 is transmitted to the real-time-process history-server 13 via the second data transmission device 15, and on this server Stored in the combined PIMS / DCS server 12.

[0021] Reporting queries from clients 1, 5 at the PIMS level and from operator workstations 2 at the monitoring and operations level (B&B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com