Forced-directed oil cooling coil configuration

A technology of strong oil and coil, applied in the field of transformers, can solve the problems of increased coil loss and geometric size, unable to meet the needs of product development, and inability to distribute the oil flow evenly in the coil, so as to reduce the flow rate, prolong the service life, and achieve a good cooling effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

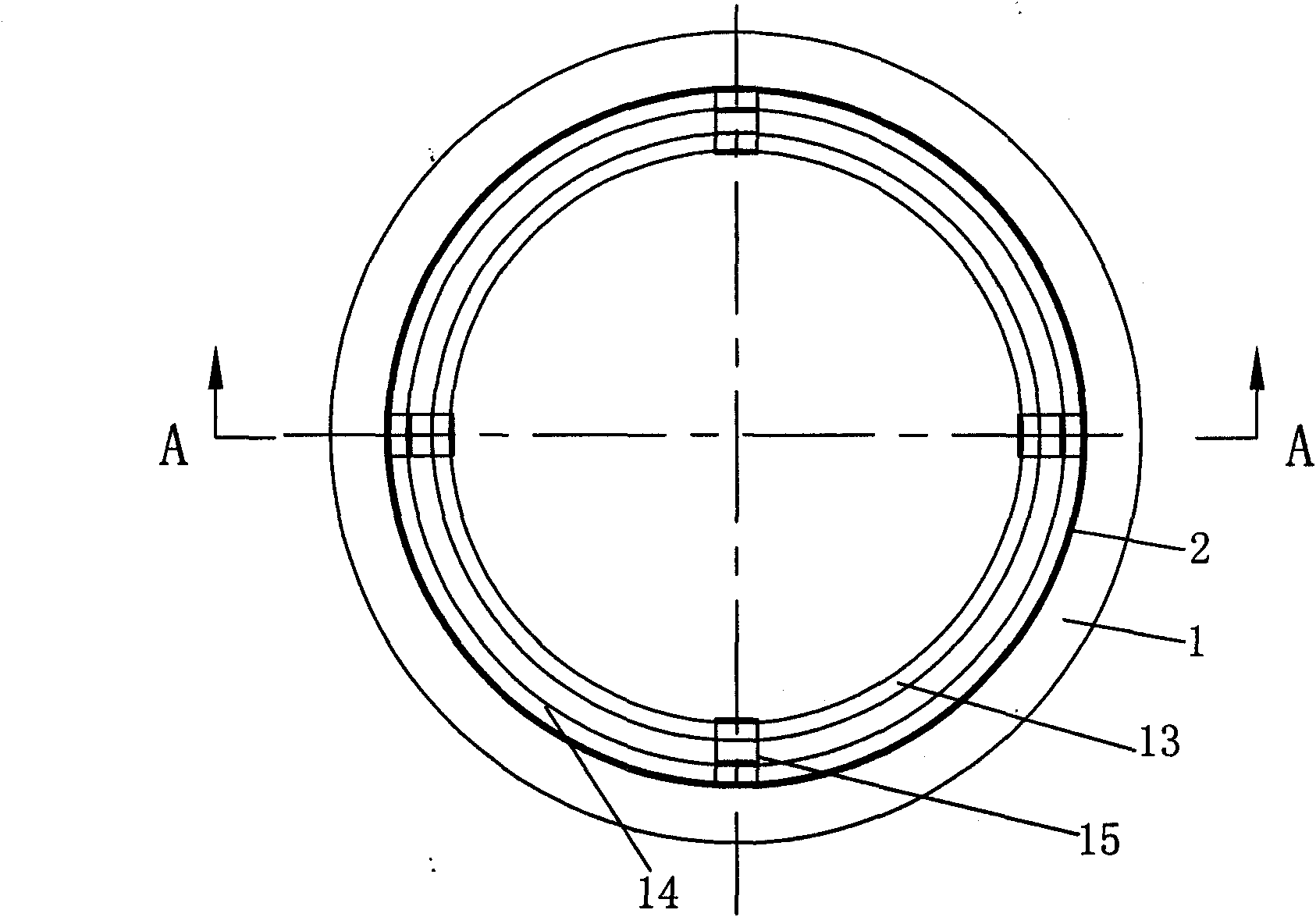

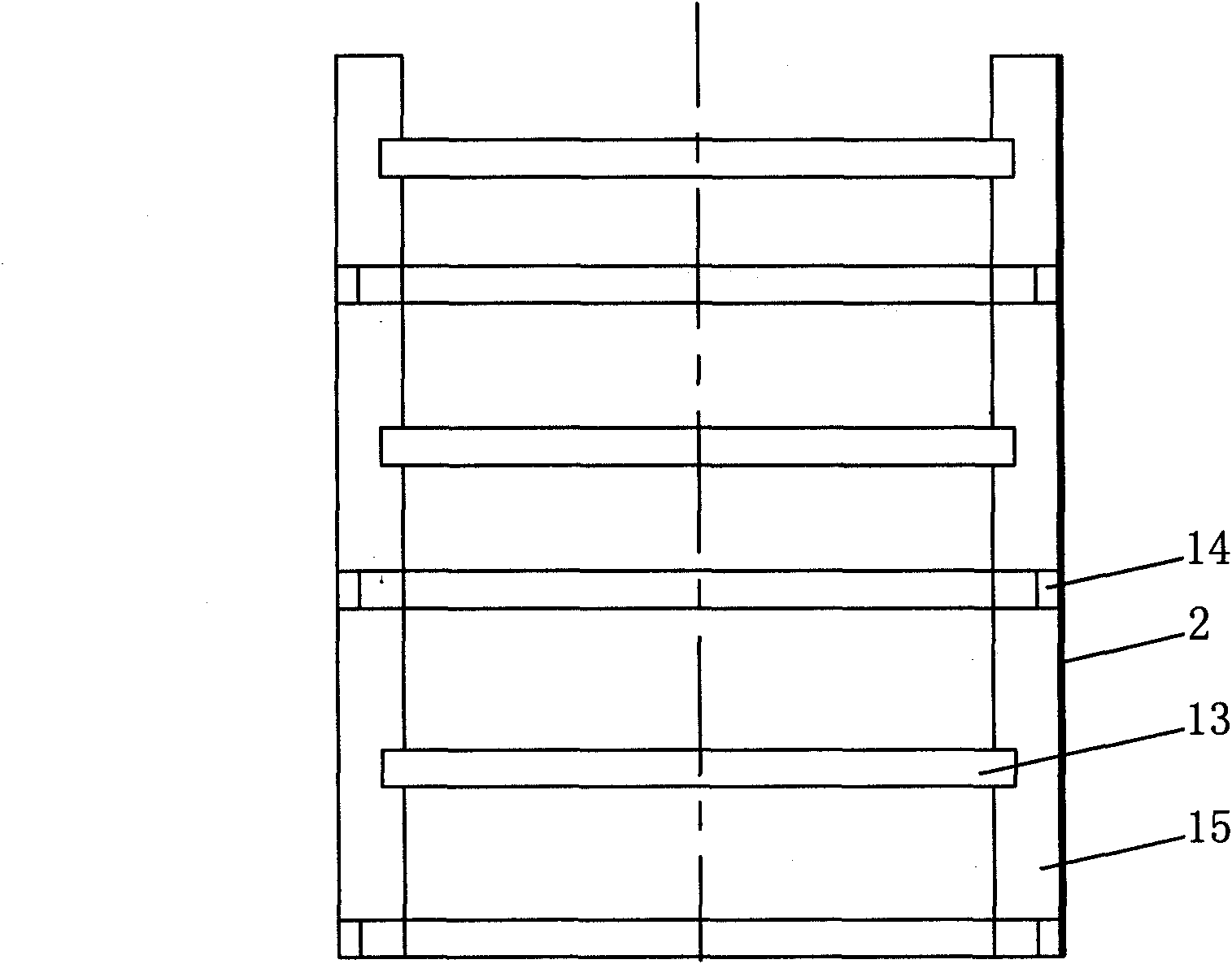

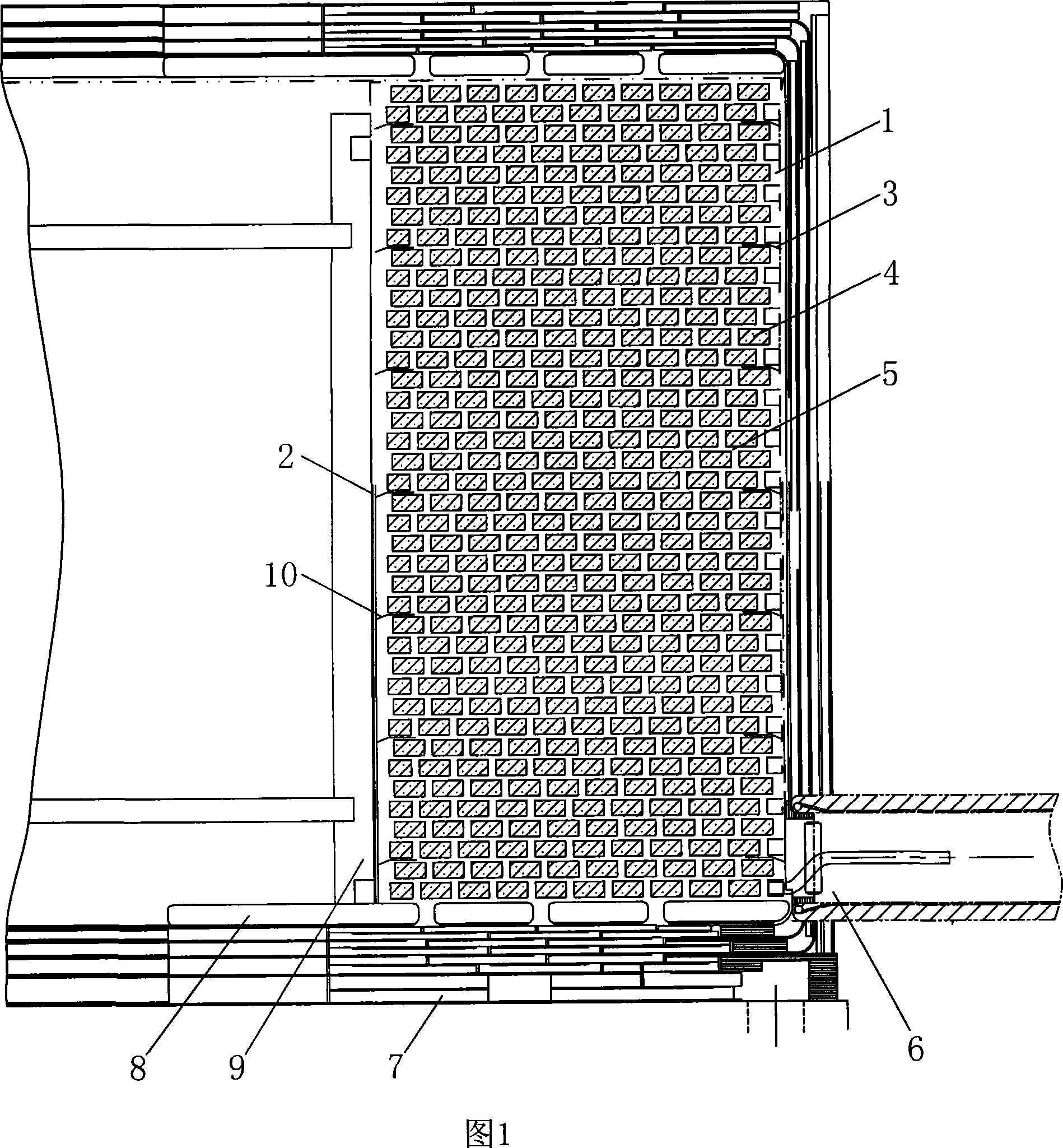

[0019] Embodiment 1: as figure 1 As shown, the present invention includes a ring coil 1, a brace structure frame 9, an inner oil baffle 10, an outer oil baffle 3, a first insulating block 8, an insulation structure 7 at the end of the ring coil and an oil blocking structure 6 at the lead-out line, A strut structure frame 9 is arranged inside the toroidal coil 1, an inner oil baffle 10 and an outer oil baffle 3 are placed on the inside and outside of the toroidal coil 1 respectively, and a paper tube 2 is placed between the strut structure frame 9 and the inner oil baffle 10 An oil blocking structure 6 is provided at the lead-out line at the lower end of the toroidal coil 1, a first insulating block 8 is provided at the upper and lower ends of the toroidal coil 1, and a coil end insulation structure is provided at the lower part of the first insulating block 8 at the lower end of the toroidal coil 1 7.

[0020] The toroidal coil 1 of this example is composed of several wires 4...

Embodiment 2

[0024] Embodiment 2: as figure 1 As shown, the present invention includes a ring coil 1, a brace structure frame 9, an inner oil baffle 10, an outer oil baffle 3, a first insulating block 8, an insulating structure 7 at the end of the coil and an oil blocking structure 6 at the lead-out line. A strut structure frame 9 is arranged inside the toroidal coil 1, an inner oil baffle 10 and an outer oil baffle 3 are arranged on the inside and outside of the toroidal coil 1, and a paper tube 2 is placed between the strut structure frame 9 and the inner oil baffle 10, An oil blocking structure 6 is provided at the lead-out line at the lower end of the toroidal coil 1, a first insulating block 8 is provided at the upper and lower ends of the toroidal coil 1, and a coil end insulating structure 7 is provided at the lower part of the first insulating block 8 at the lower end of the toroidal coil 1 .

[0025] The ring coil 1 , the insulation structure 7 at the end of the coil and the oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com