Gear shaping machine and method for manufacturing or processing gear wheel

A gear shaping machine, a technology of processing direction, applied in the direction of manufacturing tools, gear tooth manufacturing devices, gear cutting machines, etc., to achieve the effect of good precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

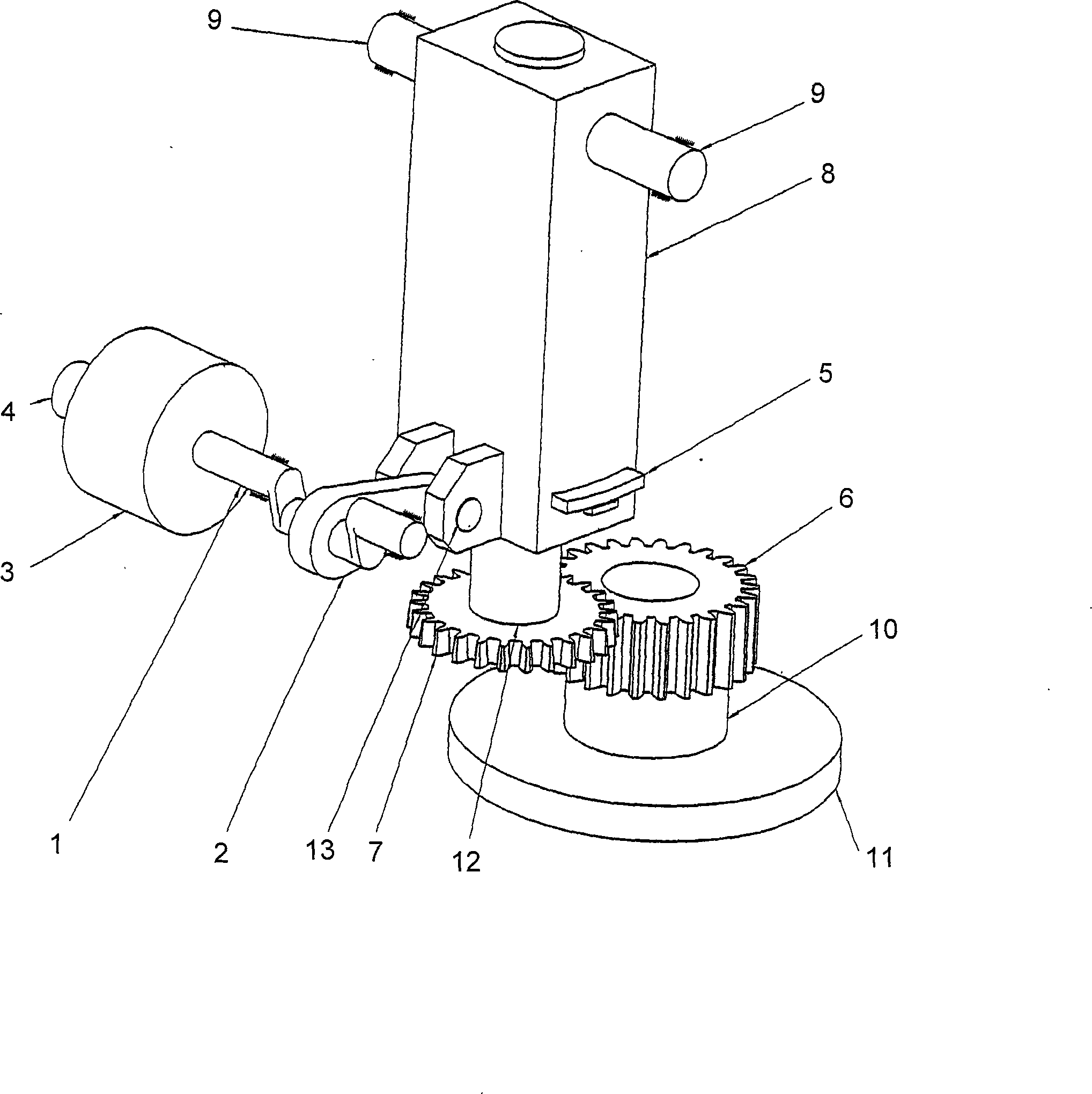

[0022] The embodiment of the gear shaping machine according to the invention has a tool 7 which is rigidly connected to a machining spindle 12 . The machining spindle 12 is in turn hydrostatically supported in the machining head 8 . Due to the reciprocating stroke movement of the machining spindle 12 , the tool 7 traverses the workpiece 6 in a reciprocating manner. The workpiece 6 is clamped on a table 11 by means of a clamp 10 . During this process, the machining spindle 12 as well as the tool 7 and the workpiece 6 are simultaneously rotated about their longitudinal axes in a geared manner. During the stroke movement, the machining head 8 , which holds the tool 7 via the machining spindle 12 , is rotatably supported on the support point 9 about an axis extending transversely to the machining direction, in order to advance the tool 7 to the workpiece 6 during the stroke movement. and exit from workpiece 6. A movement of the tool 7 transversely to the machining direction is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com